Method for manufacturing high strength steel plate hot stamping die

A technology of hot stamping die and manufacturing method, which is applied in the field of hot stamping forming, can solve the problem that the conformal cooling water channel cannot be processed, and achieve uniform cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

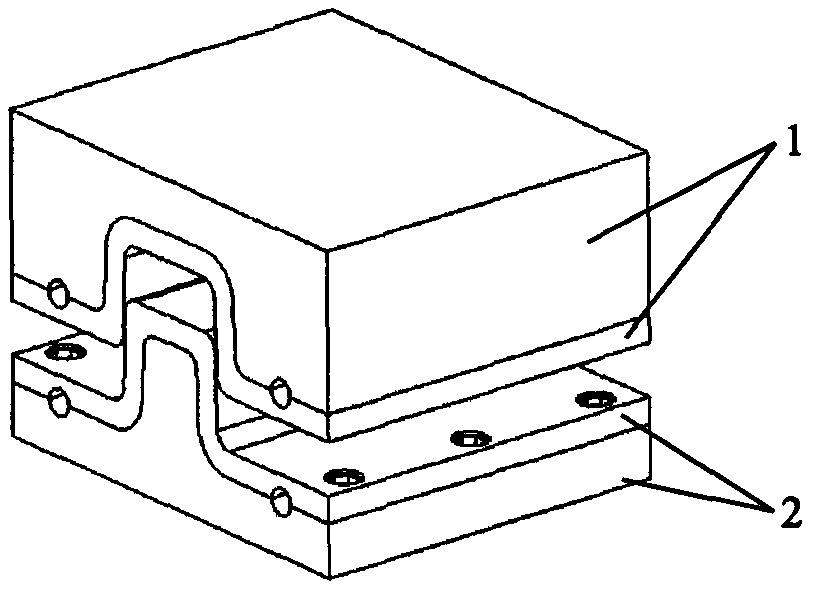

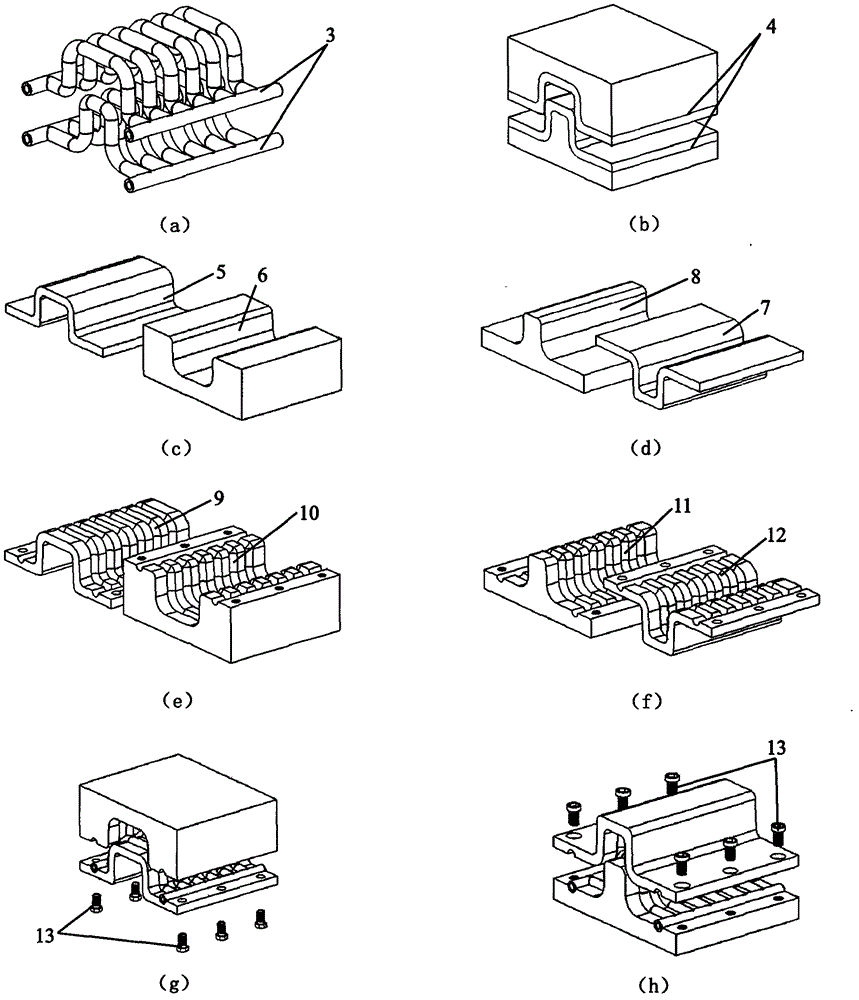

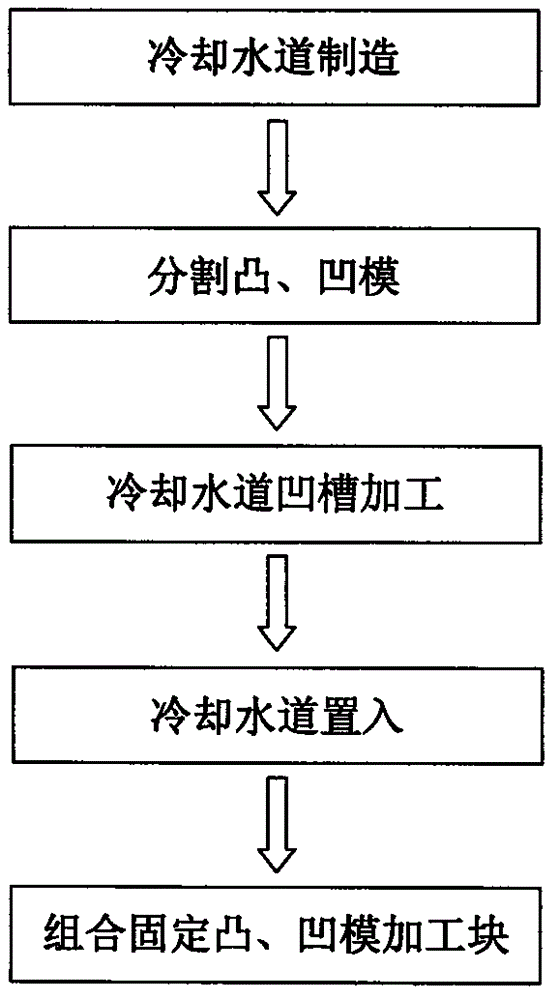

[0032] figure 1 It is the structural diagram of the convex and concave dies of the hot stamping die. First, according to the curved shape of the mold punch 2 and the concave mold 1, the metal pipe is made into a combined three-dimensional space cooling channel 3 by cutting, bending, welding, and threaded connection. Refer to figure 2 (a). In order to put the bent conformal three-dimensional space cooling water channel into the convex and concave molds, and the distance from the convex and concave model surfaces of the mold is equal everywhere, take the center position 4 of the cooling water channel as the cutting plane, refer to figure 2 (b), using methods such as wire electric discharge cutting or laser cutting, respectively divide the convex and concave molds into two processing blocks 5, 6, 7, 8, see figure 2 (c) and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com