Cooling device with a plurality of fin pitches

a cooling device and fin technology, applied in the field of cooling devices, can solve the problems of increasing manufacturing costs, difficult to secure a space, increasing dimensions and weight of cooling devices, etc., and achieve the effects of reducing temperature, reducing manufacturing costs, and suppressing the rise of cooling air temperatur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

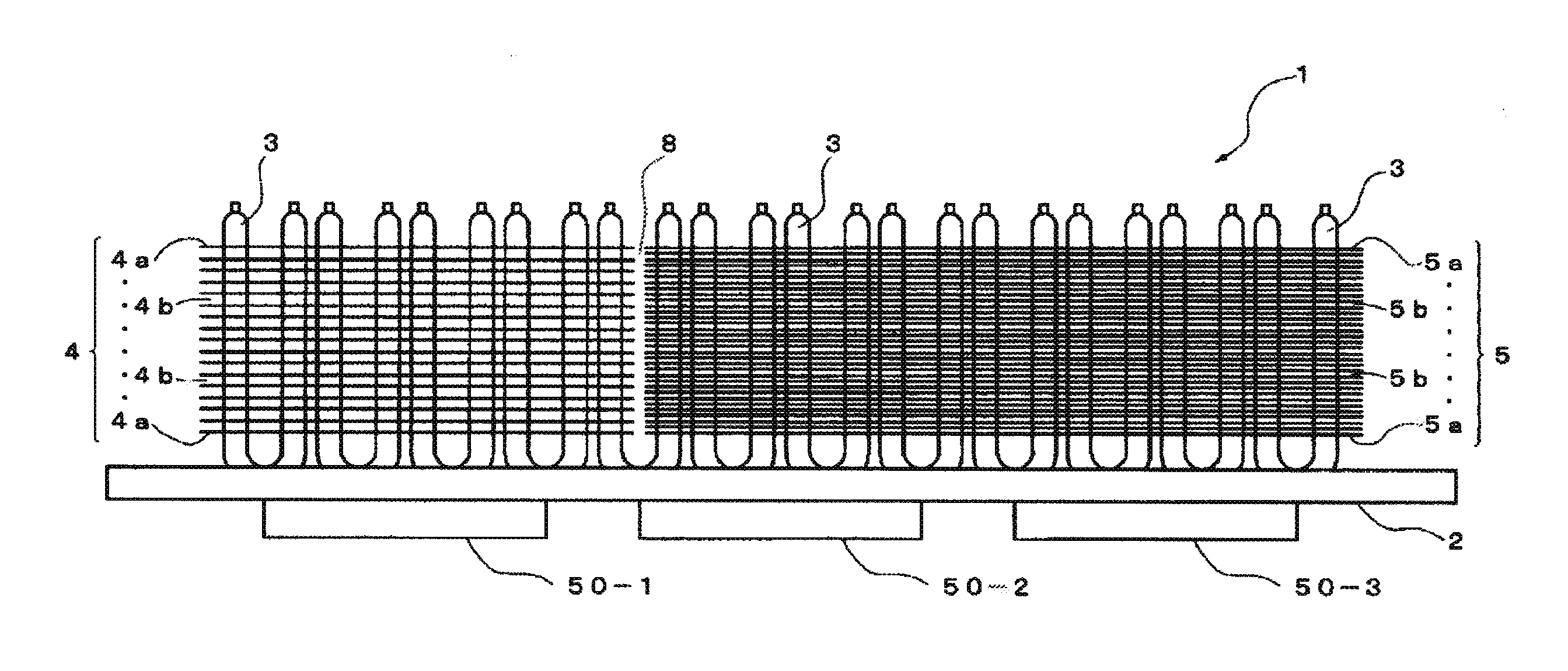

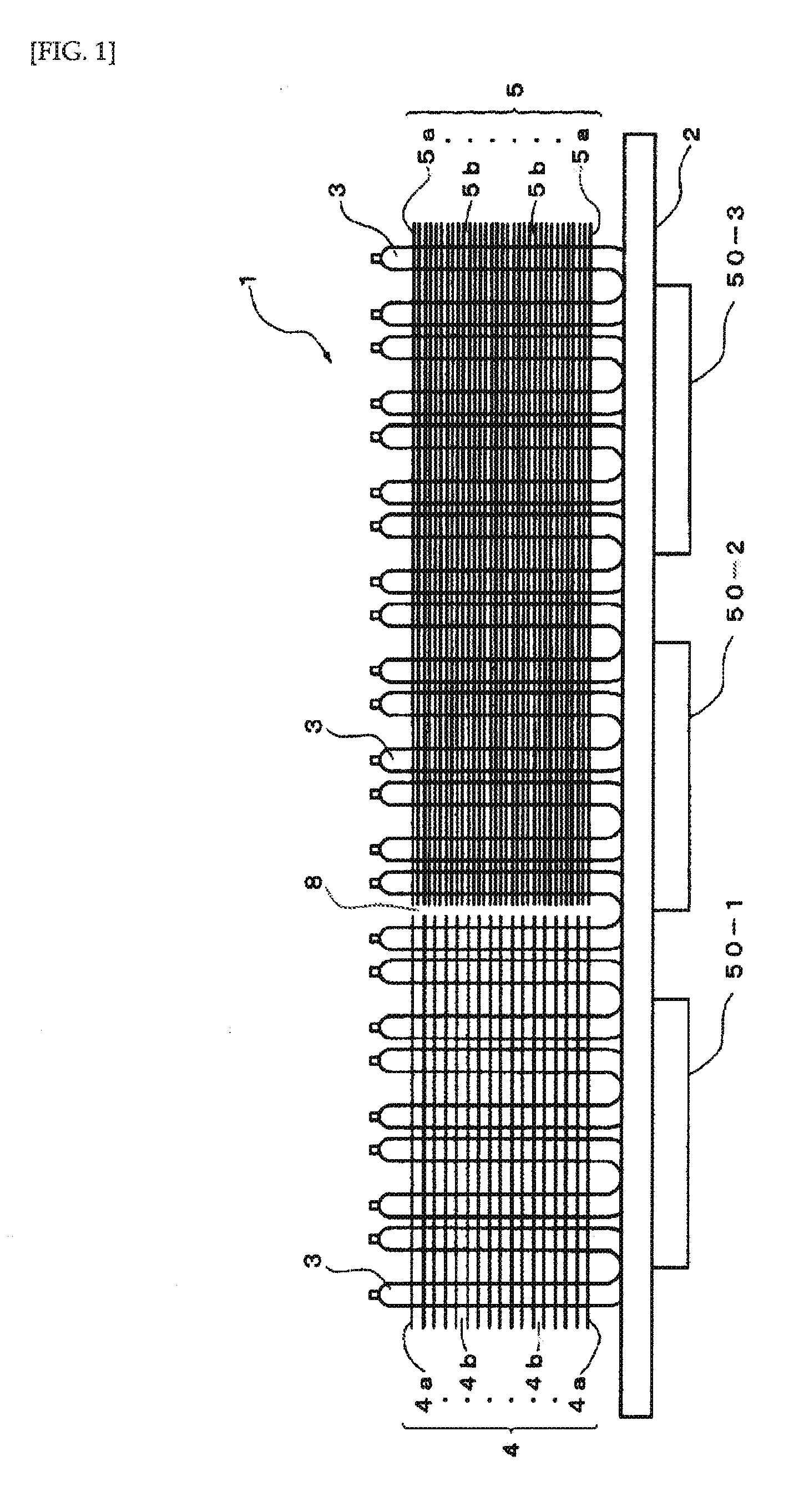

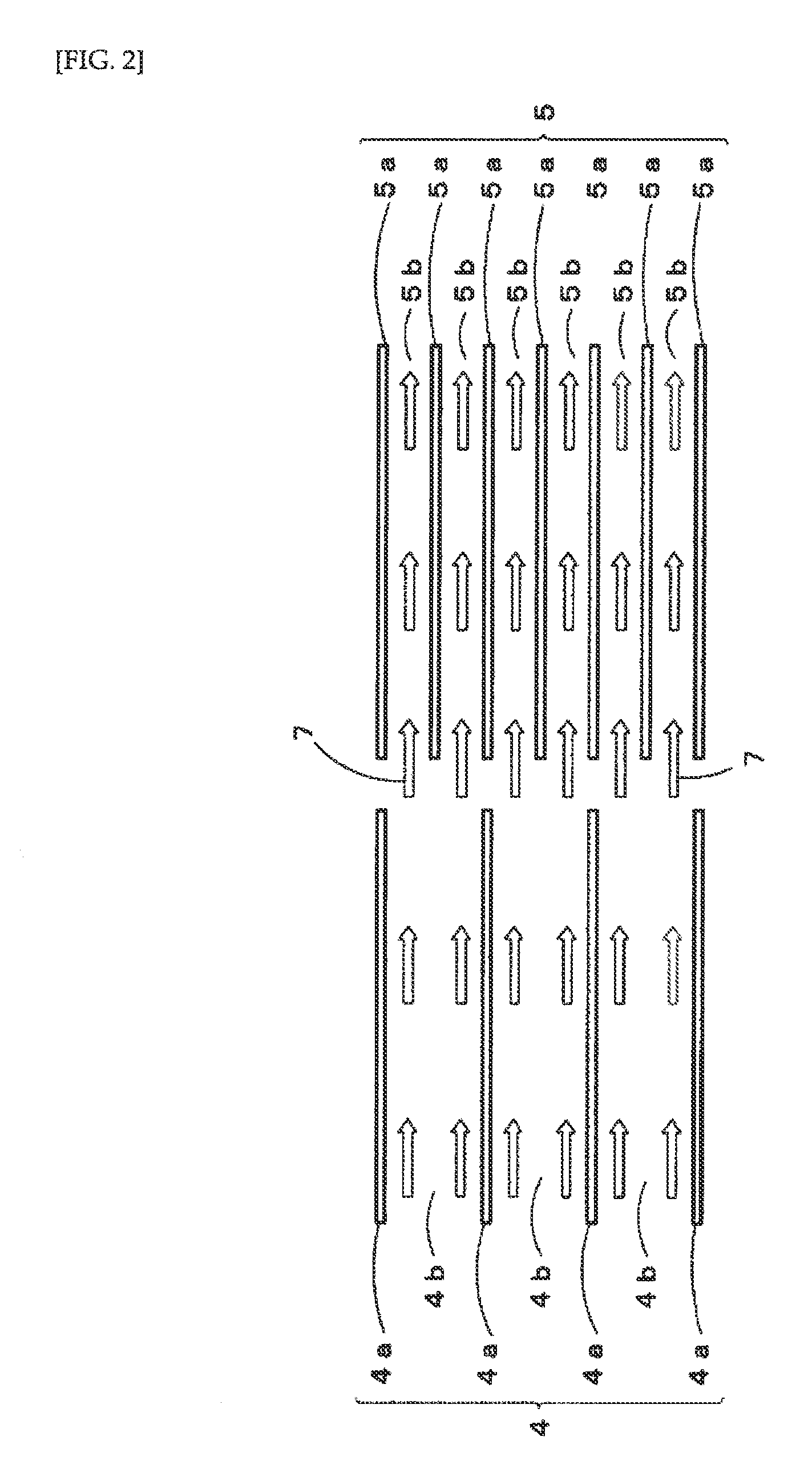

[0039]In the cooling device 1 cooling air is supplied in the direction from left to right in FIG. 1. Further, the cooling device 1 is arranged so that cooling air is supplied in parallel or substantially in parallel with the surface of the heat-receiving block 2, i.e., supplied in parallel or substantially in parallel with the surfaces of each first fin 4a and each second fin 5a. In this way, the cooling air, first, travels through each first fin 4a in the first heat radiation fin group 4. Next, the cooling air having passed through the first heat radiation fin group 4 enters the second heat radiation fin group 5. In turn, the cooling air travels through each second fin 5a in the second heat radiation fin group 5. Therefore, it is possible to prevent the first heat radiation fin group 4 and the second heat radiation fin group 5 from blocking the cooling air. Further, a gap 8 between heat radiation fin groups is formed between the first heat radiation fin group 4 and the second heat...

third embodiment

[0055]The arrangement relationship between the first fins 24a, the second fins 25a and the third fins 26a is not particularly limited as long as the gaps 24b between the first fins 24a are larger than the gaps 25b between the second fins 25a and the gaps 25b between the second fins 25a are larger than the gaps 26b between the third fins 26a. In this embodiment, since the pressure loss due to the first heat radiation fin group 24 can be decreased, a reduction in the amount and velocity of the cooling air passing through the second heat radiation fin group 25 can be suppressed, and the number of first fins 24a is reduced so that a temperature rise of the cooling air having passed through the first heat radiation fin group 24 is suppressed. As the pressure loss due to the second heat radiation fin group 4 can be also decreased, a reduction in the amount and velocity of the cooling air passing through the third heat radiation fin group 26 can be suppressed, and the number of second fins...

second embodiment

[0059]In the cooling device 31 heat-generating elements, which are objects to be cooled, are disposed on the back side of the heat-receiving block 32, on which fins are not mounted. The heat-generating elements are thermally connected to each other and assigned, in the order from windward to leeward, reference numerals 350-1, 350-2, 350-3.

[0060]The arrangement relationship between the first fins 34a, the second fins 35a and the third fins 36a is not particularly limited as long as the gaps 34b between the first fins 34a are larger than the gaps 35b between the second fins 35a and the gaps 35b between the second fins 35a are larger than the gaps 36b between the third fins 36a. In this embodiment, a reduction in the amount and velocity of the cooling air passing through the second heat radiation fin group 35 and the third heat radiation fin group 36 can be suppressed. Also, the numbers of first fins 34 and second fins 35a are reduced so that a temperature rise of the cooling air havi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com