Micro-pump based on super-magnetostrictive film driver

A technology of giant magnetostriction and reverse magnetostriction, which is applied to components of pumping devices for elastic fluids, pumps with flexible working elements, pumps, etc., and can solve problems such as low drive frequency, small flow rate, and high drive voltage. problem, to achieve the effect of high driving frequency, small driving current and large flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

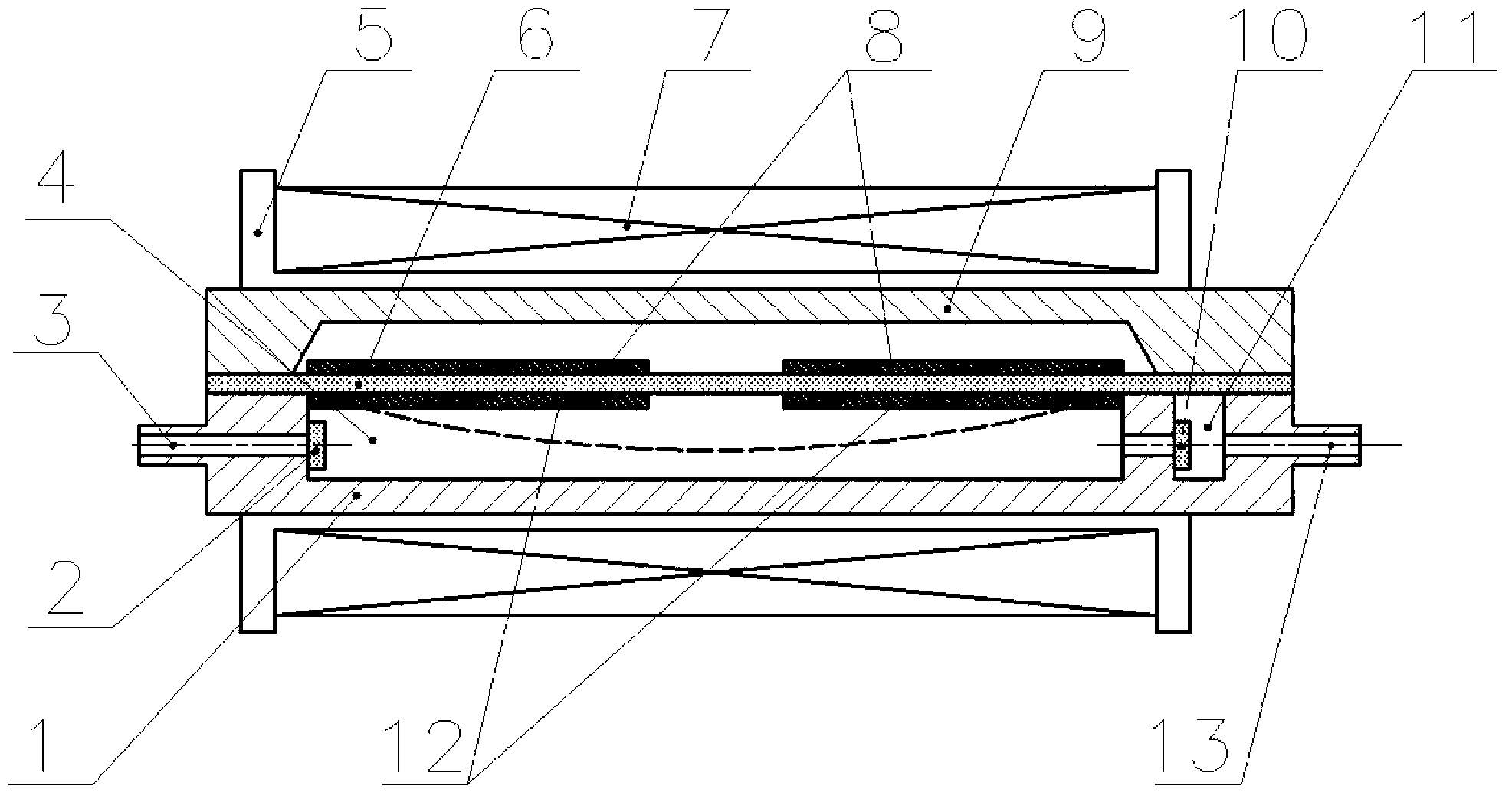

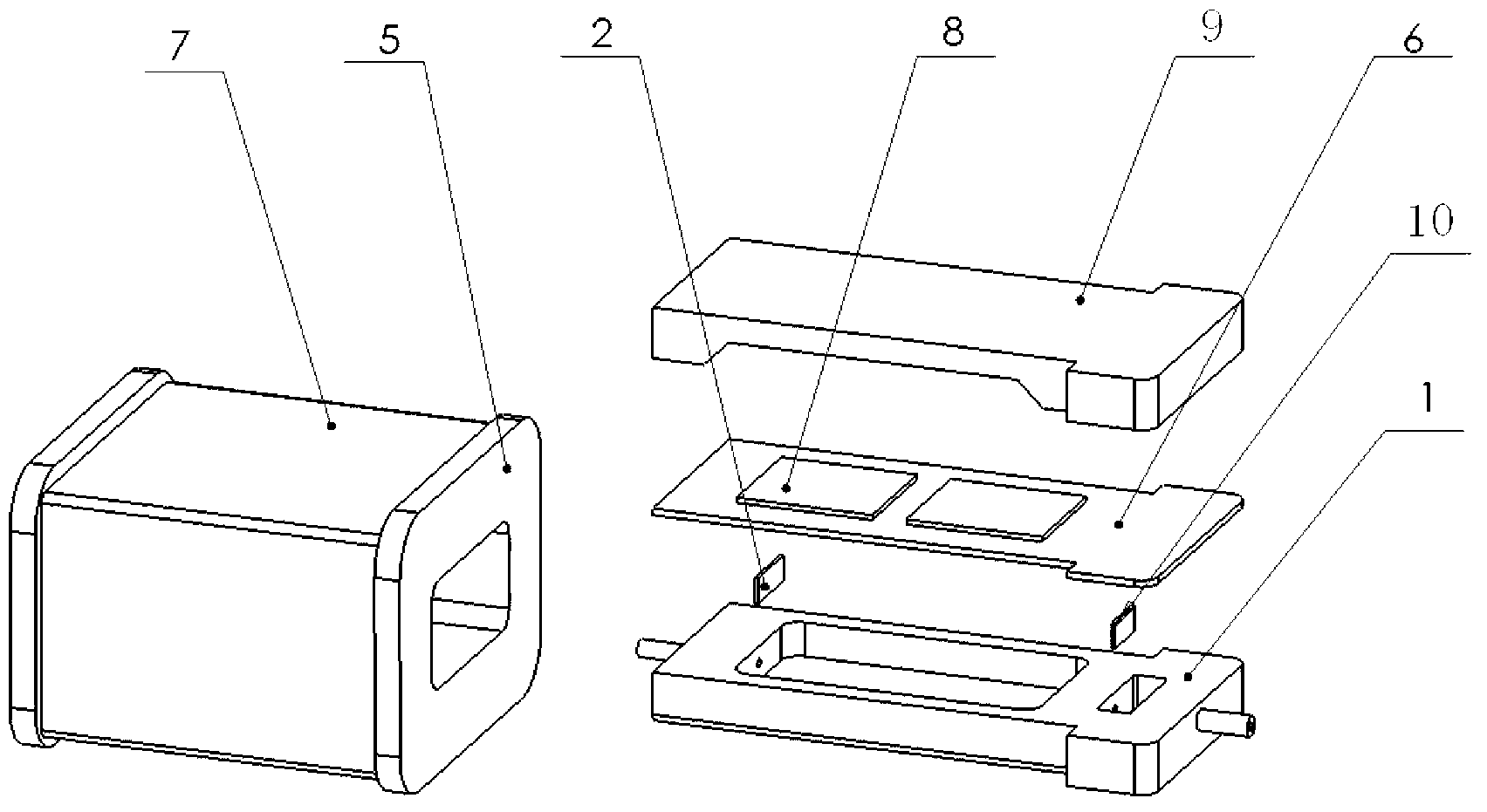

[0018] As shown in the figure, the micropump includes a lower pump body 1, a substrate 6 and an upper pump body 9 sequentially laminated on the lower pump body 1, the upper side of the substrate 6 is coated with a film 8 with a positive magnetostrictive effect, and the lower side is coated with a film 8 with a positive magnetostrictive effect. There is a film 12 with inverse magnetostrictive effect; the bottom surface of the substrate 6 and the lower pump body constitute the pump cavity 4 and the valve cavity 11, and the pump cavity 4 and the valve cavity 11 are in a communication state through a through hole; the pump cavity is connected There is a liquid inlet pipe 3, and the valve cavity is connected with a liquid outlet pipe 13. The connection between the liquid inlet pipe 3 and the pump chamber 4 is provided with a liquid inlet valve film 2, and the liquid inlet valve f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com