High-torque double-electromagnet-head normally-closed type safety brake

A safety brake, double electromagnet technology, applied in the direction of brake actuators, gear shifting mechanisms, mechanical equipment, etc., can solve the problems of increased yoke and armature, increased processing difficulty, increased heat, etc., to achieve increased safety performance, Easy and safe control, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

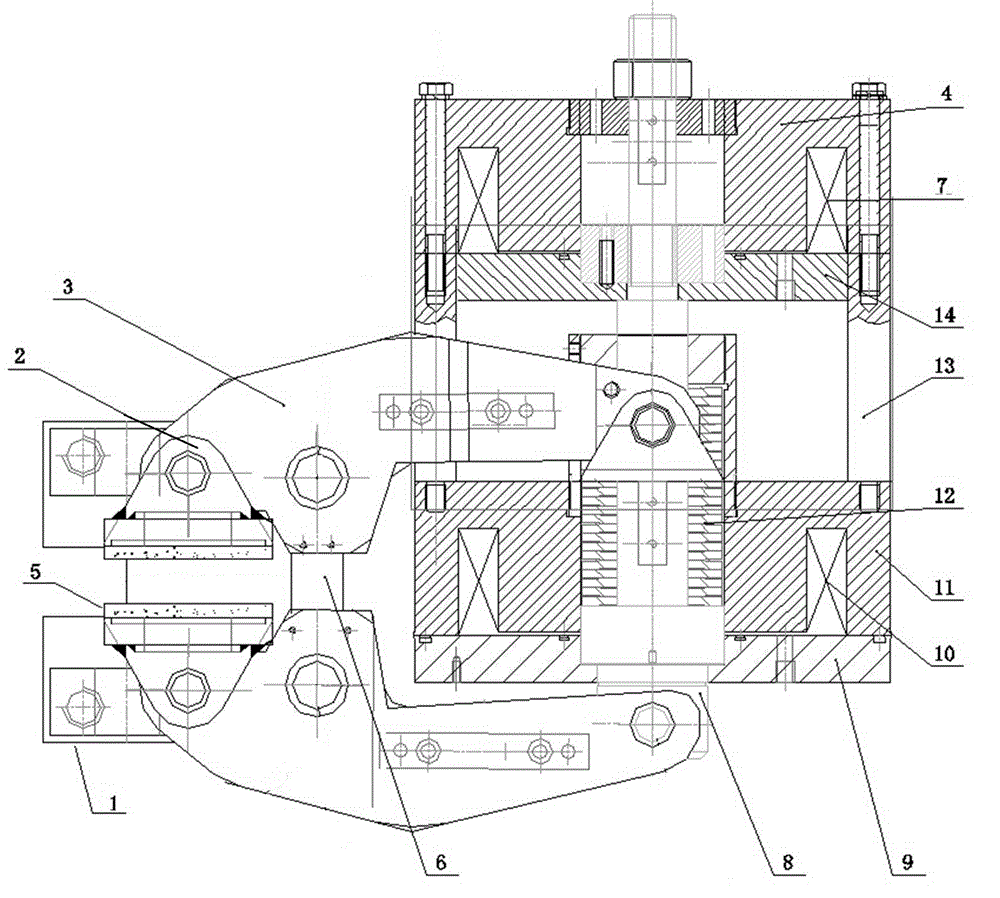

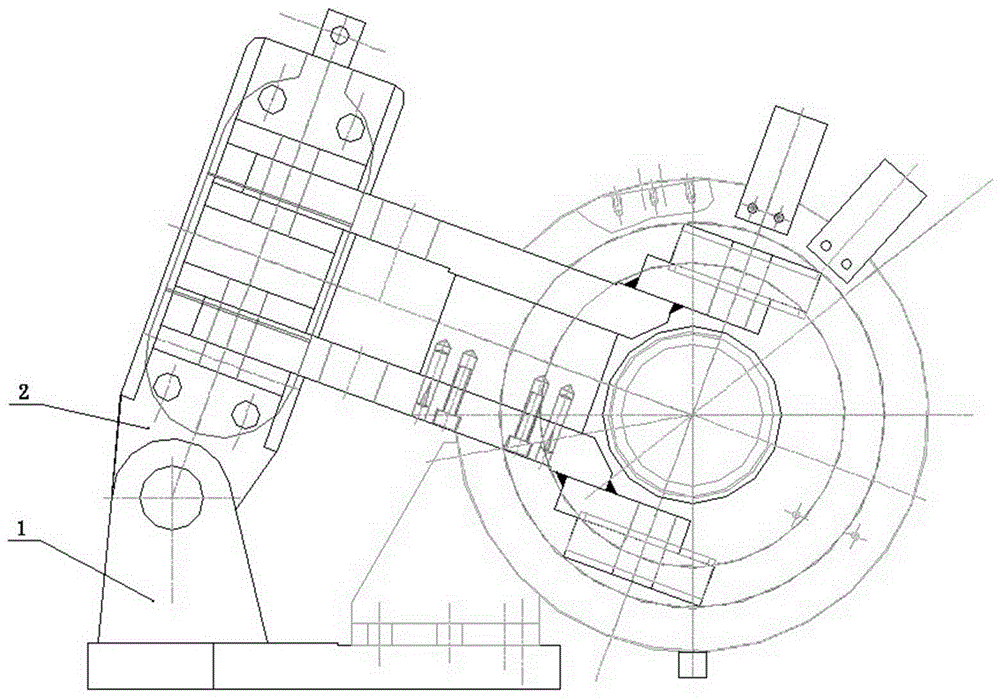

[0013] Such as figure 1 , figure 2 As shown, a high-torque double electromagnet head normally closed safety brake includes a symmetrically arranged brake arm 3. One end of the symmetrically arranged brake arm is connected to the stepped shaft, and the other end is connected to the brake shoe. The brake shoe passes through the The pin shaft is connected to the base, and an adjusting screw 6 with positive threads and negative threads at both ends is installed between the two brake arms. The front end of the brake arm is a friction plate assembly, and the friction plate assembly includes a The brake shoe 2, the friction plate 5 installed on the brake shoe (the part where the friction plate is installed on the brake shoe has its own magnetic force, which makes the disassembly and installation of the friction plate simple and convenient). The end of the brake arm is a brake power device connected by a stepped shaft, which is composed of two sets of electromagnet devices connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com