Intrinsic frequency measuring method for long and thin object

A technology for natural frequency and slender objects, applied to measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of inapplicability and difficulty in distinguishing the natural frequencies of longitudinal waves or transverse waves, etc., and achieve accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

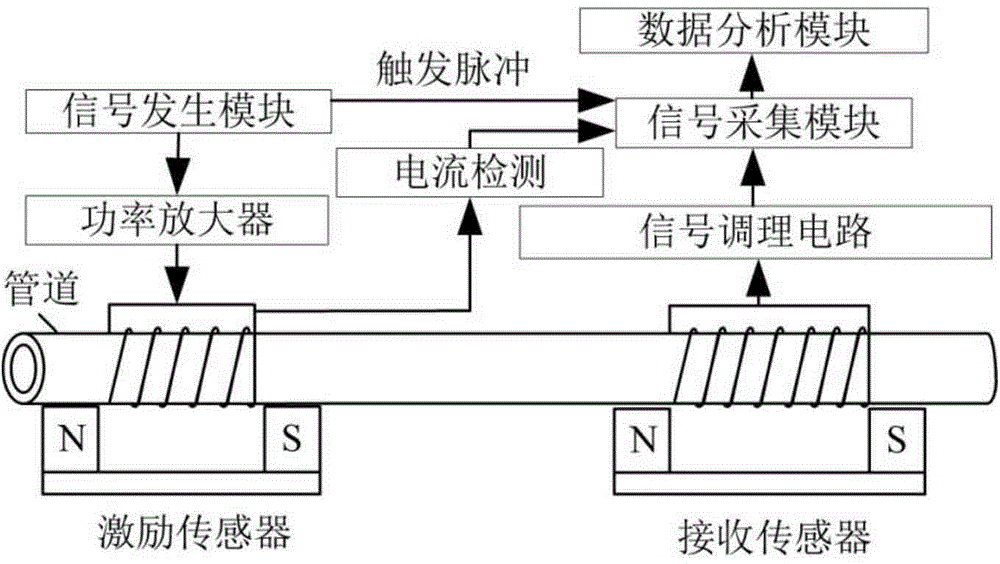

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] as attached figure 1 Shown is a measured pipeline longitudinal vibration natural frequency measuring device adopted by the present invention, wherein N and S respectively represent the two poles of the bias magnetic field, N is an N pole, and S is an S pole; the device includes the following modules:

[0034] Signal generation module: use a combination of a microcontroller and a signal generation circuit to generate a pulse signal that triggers the signal acquisition module and a wide-spectrum pulse excitation signal that is output to the power amplifier;

[0035] Power amplifier: composed of operational amplifiers and power devices to generate the excitation current i(t);

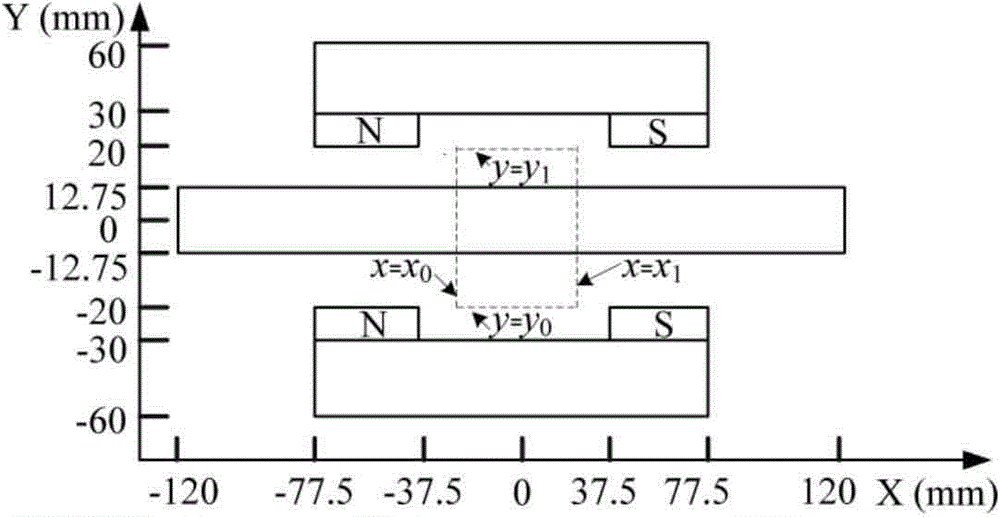

[0036] Sensors: including excitation sensors and detection sensors, which are composed of a bias magnetic field and a coil respectively. The bias magnetic field is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com