Giant magnetostrictive micro-displacement self-sensing driving method and actuator

A technology of giant magnetostriction and driving method, applied in the direction of control using feedback, can solve problems such as the influence of interference force, and achieve the effects of improving measurement accuracy, positioning accuracy, and suppressing nonlinearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

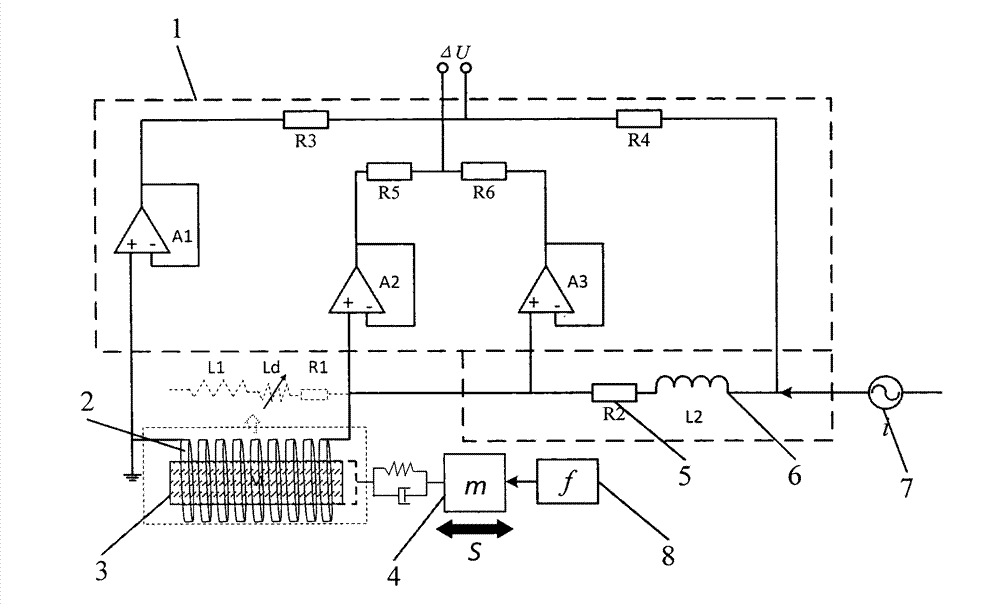

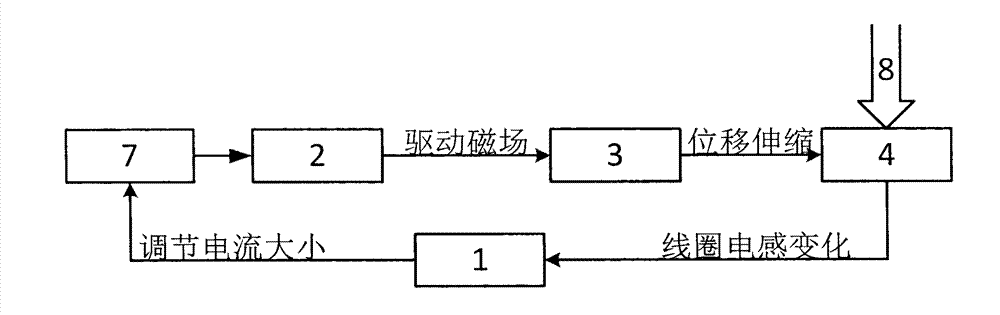

[0028] A giant magnetostrictive micro-displacement self-sensing driving method, the implementation steps of the method will be described in detail below in conjunction with the accompanying drawings:

[0029] In the first step, the constant current source amplifying circuit 7 provides excitation current for the cylindrical coil 2 of the giant magnetostrictive actuator to make it generate a uniform magnetic field. When the driving magnetic field is stable, the giant magnetostrictive rod 3 produces a stretching effect to make the super The output displacement of the magnetostrictive micro-displacement driver, at this time, the equivalent resistance R of the energized cylindrical coil 2 1 and inductance L 1 A certain voltage division is generated in the drive circuit;

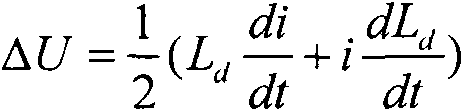

[0030] In the second step, the inductance bridge circuit 1 for measuring the inductance variation of the cylindrical coil 2 is integrated on the basis of the constant current source amplifier circuit 7, and the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com