Biplane oil driven micropump based on giant magnetostrictive film driver

A giant magnetostrictive and coil-driven technology, applied to pumps with flexible working elements, pumps, machines/engines, etc., can solve the problems of insufficient magnetic field strength, low performance and low efficiency of micro-pumps, and achieve load capacity Strong, avoid frequency doubling effect, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

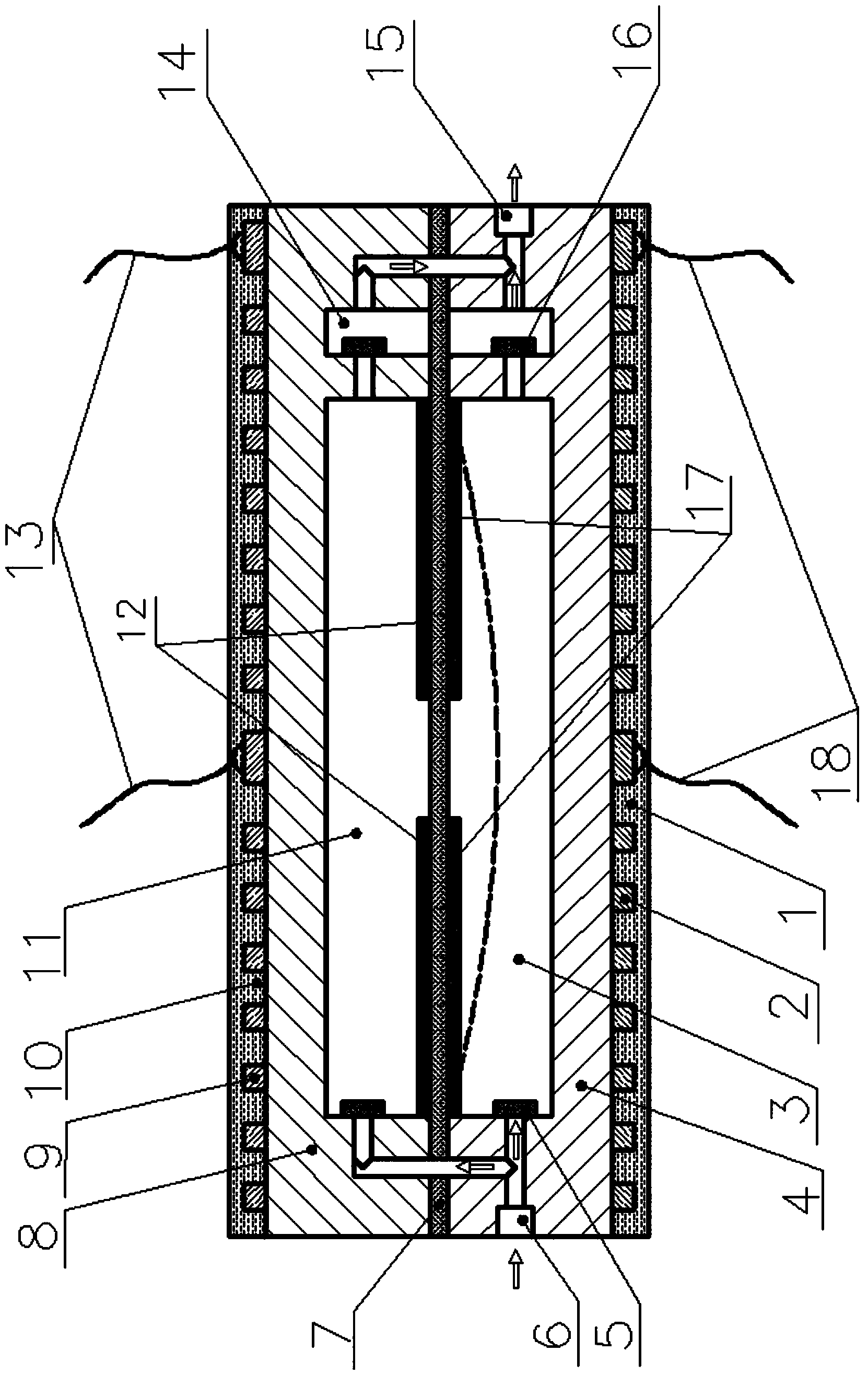

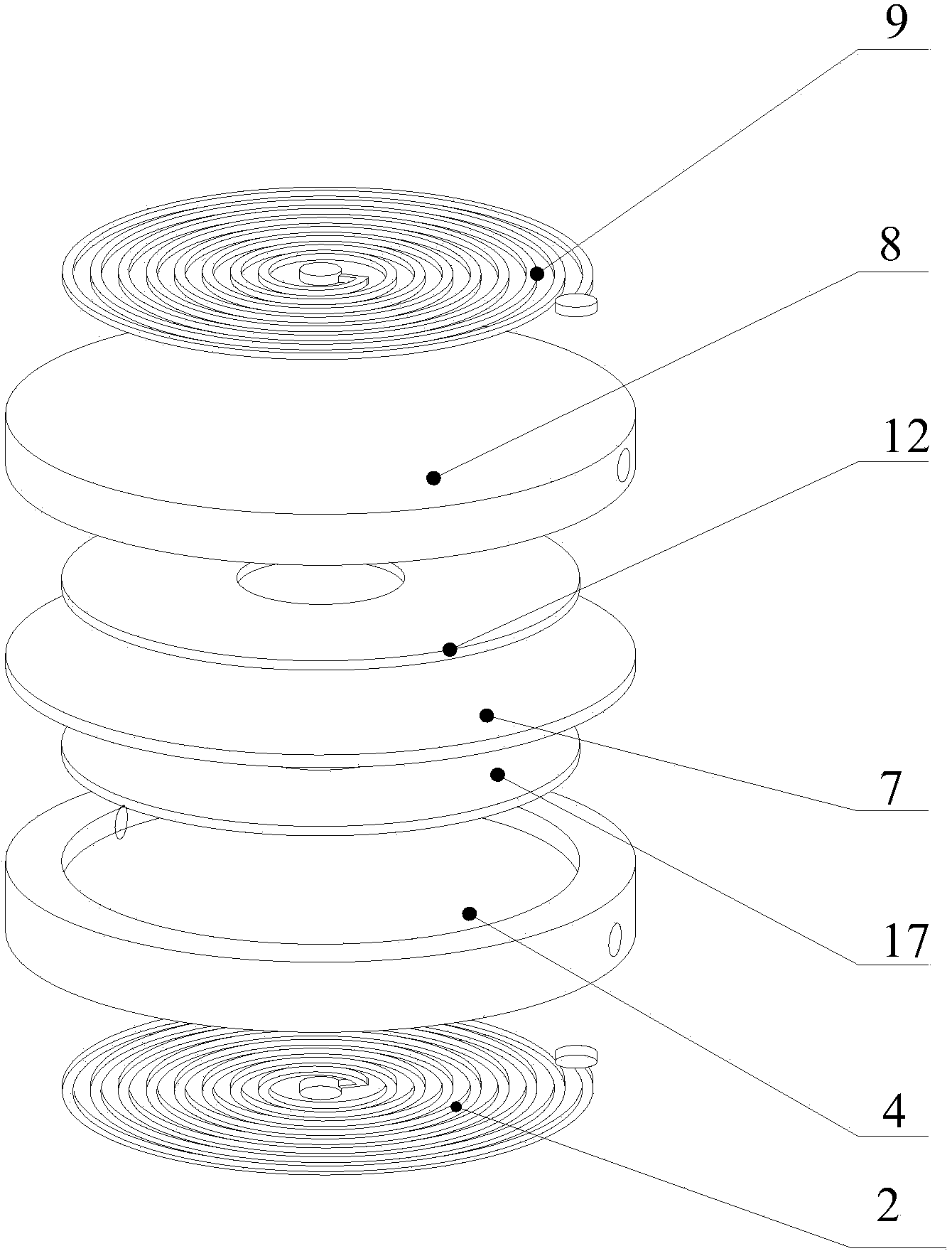

[0030] The present invention is described further below:

[0031] combine figure 1 , figure 2 : A double planar coil-driven micropump based on a giant magnetostrictive film driver, including a pump body, a substrate 7 that divides the pump body into upper and lower pump bodies, and an upper plane spiral coil is provided on the upper surface of the upper pump body 8 9. The upper plane spiral coil 9 is electrically connected to the external AC power supply through the upper coil electrode pair lead wire 13, the upper surface of the substrate 7 is provided with a positive magnetostrictive effect film 12, and the lower surface is provided with a reverse magnetostrictive effect film 17; The pump body is provided with a liquid inlet 6 and a liquid outlet 15. The pump body is provided with a valve chamber 14. The substrate 7 and the upper pump body 8 form an upper liquid chamber 11, and the substrate 7 and the lower pump body 4 form a lower liquid chamber. 3. The liquid inlet 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com