Bilateral mid-axle torque sensor of booster bicycle based on converse magnetostriction effect

A technology of assisting bicycles and inverse magnetostriction, which is applied in the direction of instruments, torque measurement, and vehicle components, can solve the problems of complex mechanical structure, high technical difficulty, and low reliability, and achieve high safety, good repeatability, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

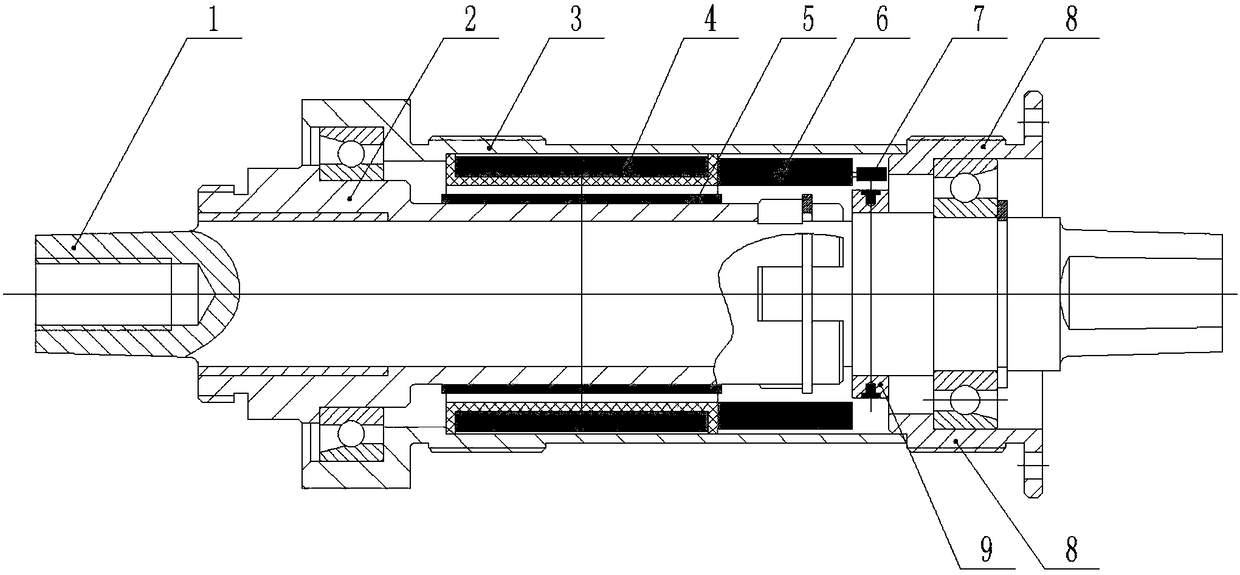

[0021] Combine below figure 1 In this embodiment, a torque sensor based on the inverse magnetostrictive effect of a double-sided bottom bracket for a power-assisted bicycle includes a through shaft 1, an elastic sleeve 2, a bottom bracket cover 3, a coil assembly 4, a magnetostrictive coating 5, and a circuit board 6. , Hall sensor 7, bottom cover 8 and multi-stage magnetic ring 9, the through shaft 1 and the elastic sleeve 2 are connected by a key, the elastic sleeve 2 is rotatably connected in the bottom sleeve 3, the through shaft 1 The right end of the shaft is rotatably connected to the bottom end cover 8, the outer surface of the elastic sleeve 2 is coated with a magnetostrictive coating 5, and the cavity between the bottom sleeve 3 and the elastic sleeve 2 is provided with a coil assembly 4 and the circuit board 6, the through shaft 1 is fixedly connected with a multi-stage magnetic ring 9, the Hall sensor 7 is arranged between the multi-stage magnetic ring 9 and the cen...

specific Embodiment approach 2

[0022] Combine below figure 1 This embodiment will be described. This embodiment will further explain the first embodiment. The magnetostrictive coating 5 is arranged on the stressed part of the elastic sleeve 2, and the coil assembly 4 is coaxially arranged on the surface of the elastic sleeve 2 to have magnetostriction. The position of the coating 5, the coil assembly 4 is an excitation coil and a measuring coil, and the magnetostrictive coating 5 and the coil assembly 4 constitute a torque detection unit.

specific Embodiment approach 3

[0023] Combine below figure 1 To illustrate this embodiment, this embodiment will further explain the first or second embodiment. The coil assembly 4 is made of enameled copper wire, and the enameled copper wire is coaxially arranged on the surface of the elastic sleeve 2. In the position of the stretch coating 5, there is insulating paper between two adjacent layers. The measurement principle is: the coil assembly 4 contains two coils, one is an excitation coil and the other is an induction coil. The excitation coil is used for magnetostriction. When the coating is excited, when the magnetostrictive coating deforms with the torque, the electromagnetic induction intensity detected by the induction coil changes, thereby converting the corresponding relationship between the magnetic induction intensity and the current torque; the Hall sensor 7 is used to measure Rotation speed, the Hall sensor 7 is selected because of its firm structure, small size, light weight, long life, easy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com