Patents

Literature

104results about How to "Low requirements for measurement environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

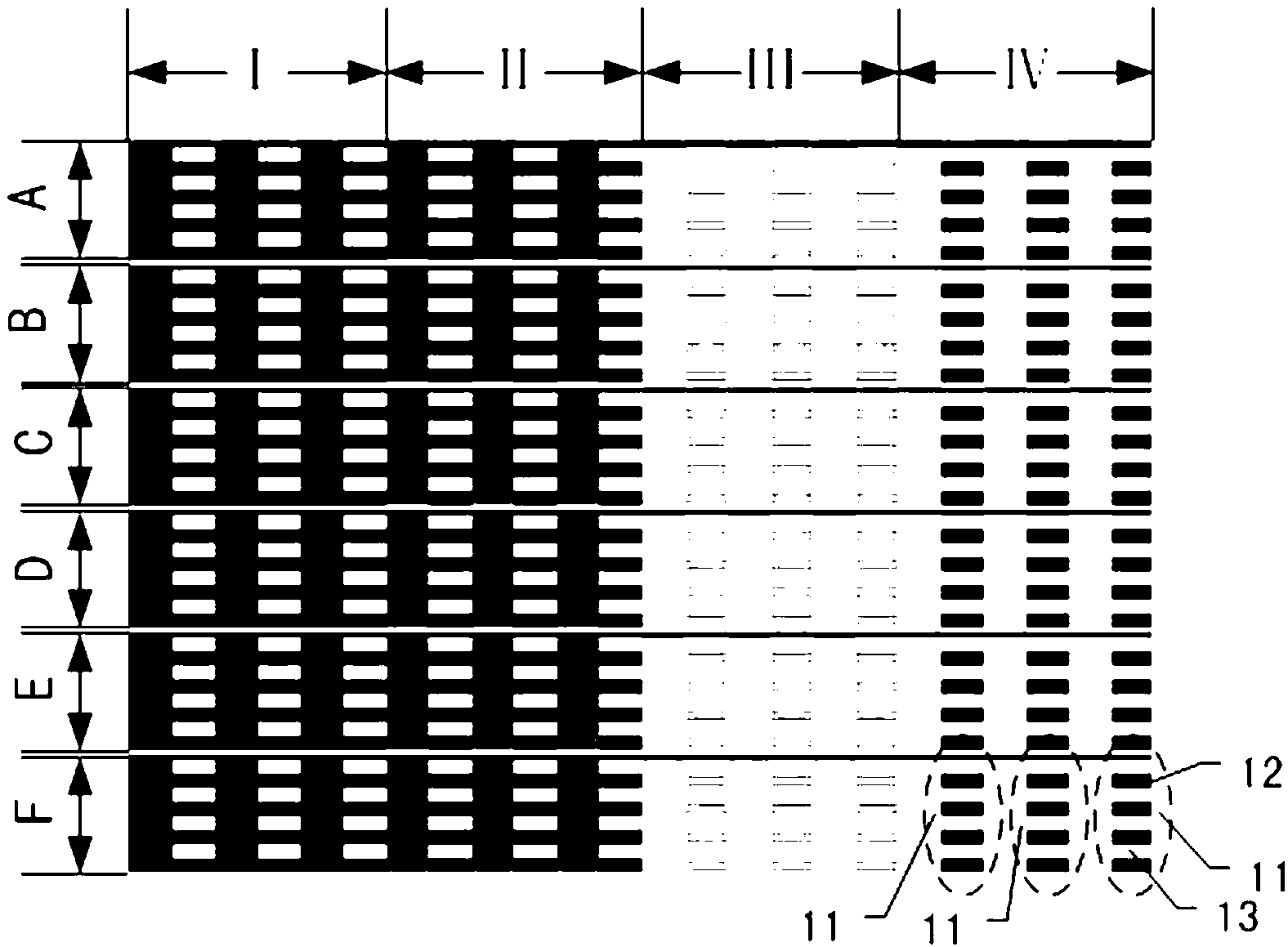

Method and device for three-dimensionally reestablishing surface contour of human body

InactiveCN102175179AImprove reconstruction accuracyImprove stabilityUsing optical meansHuman bodyGrating

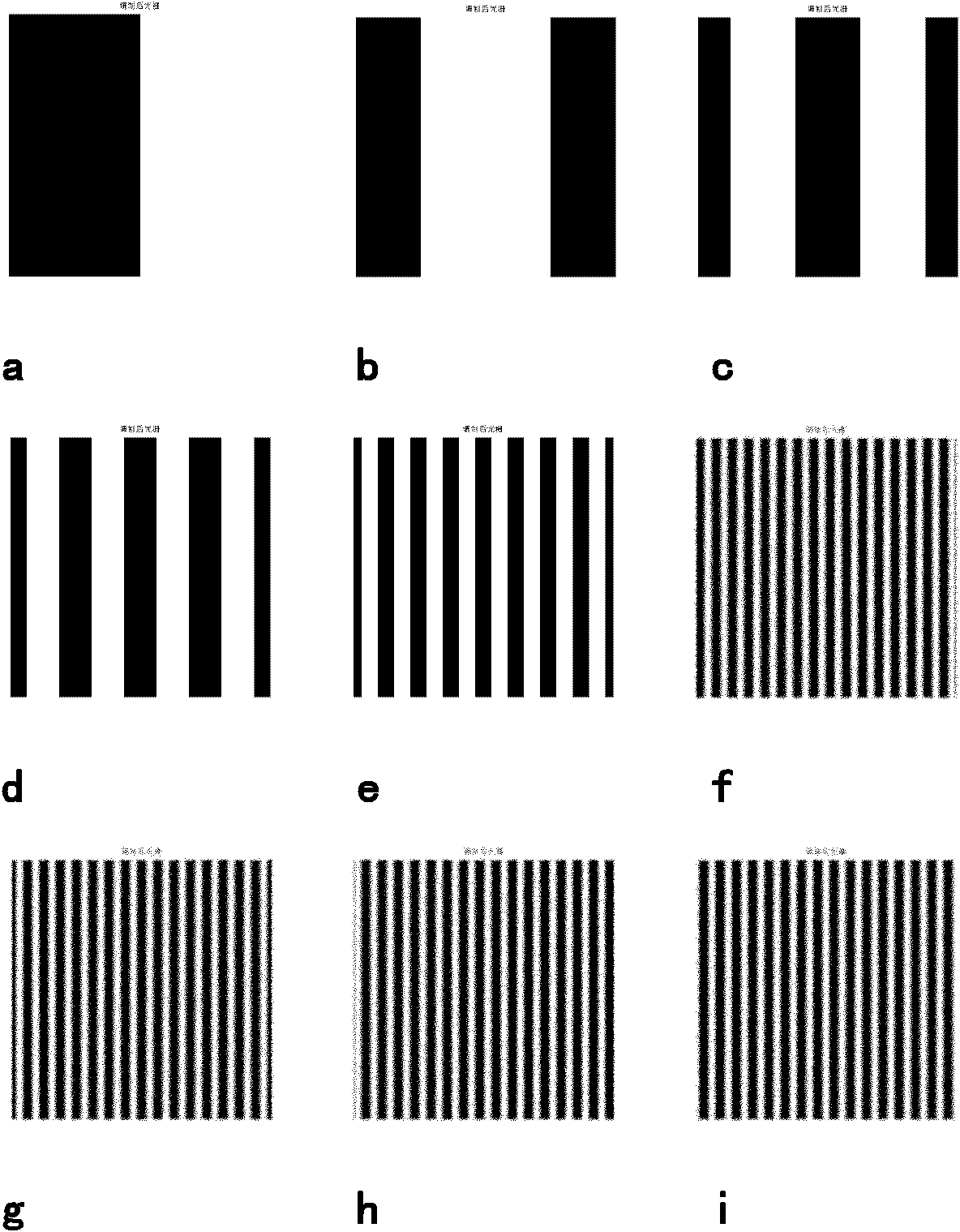

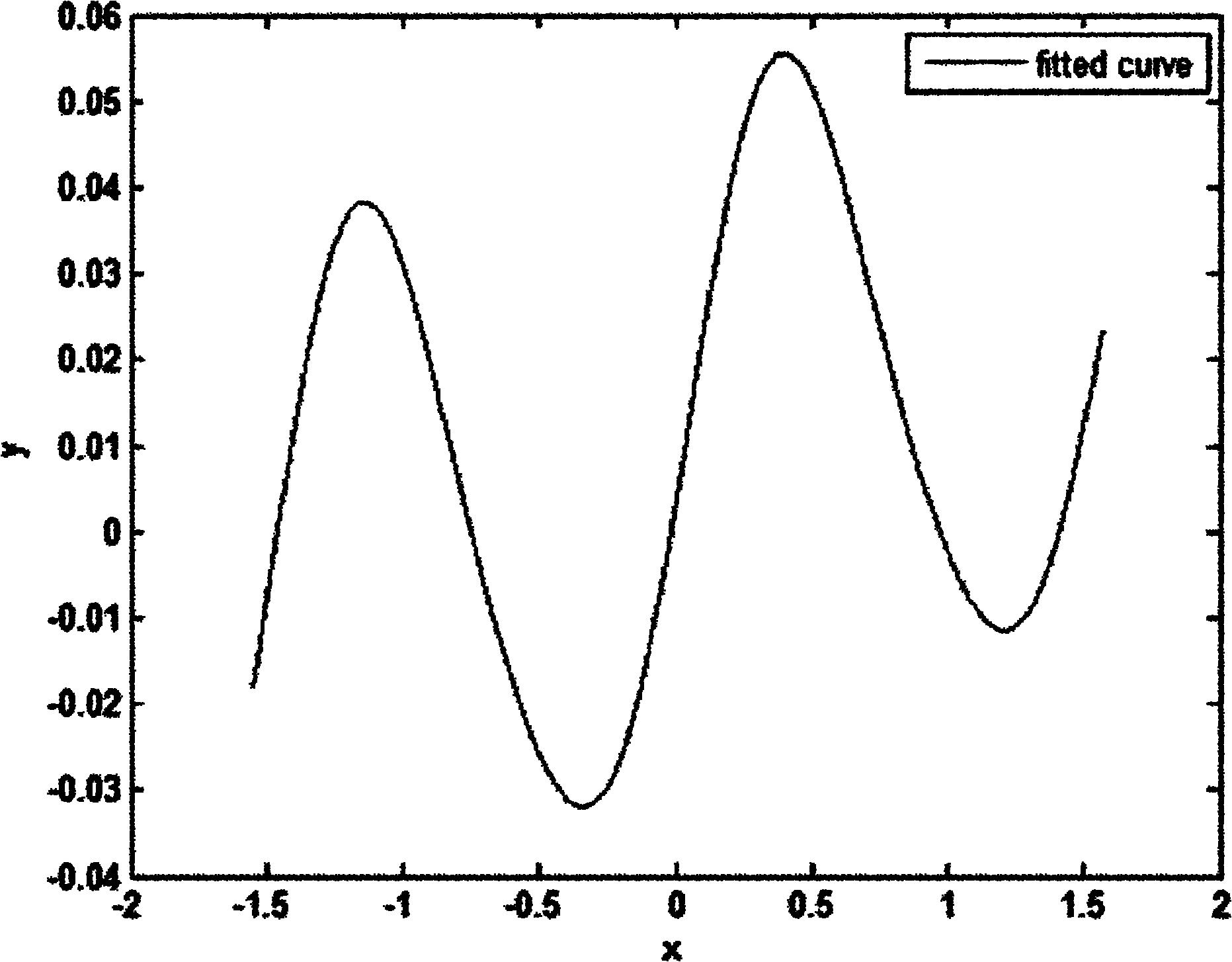

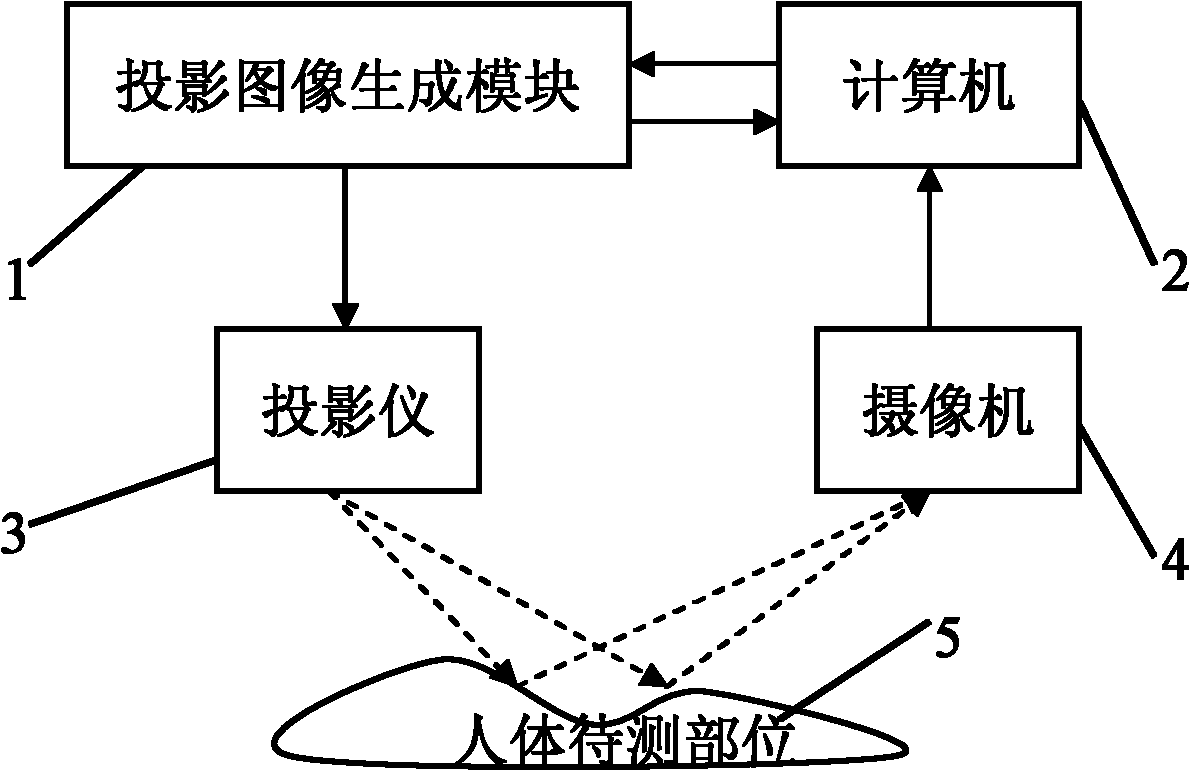

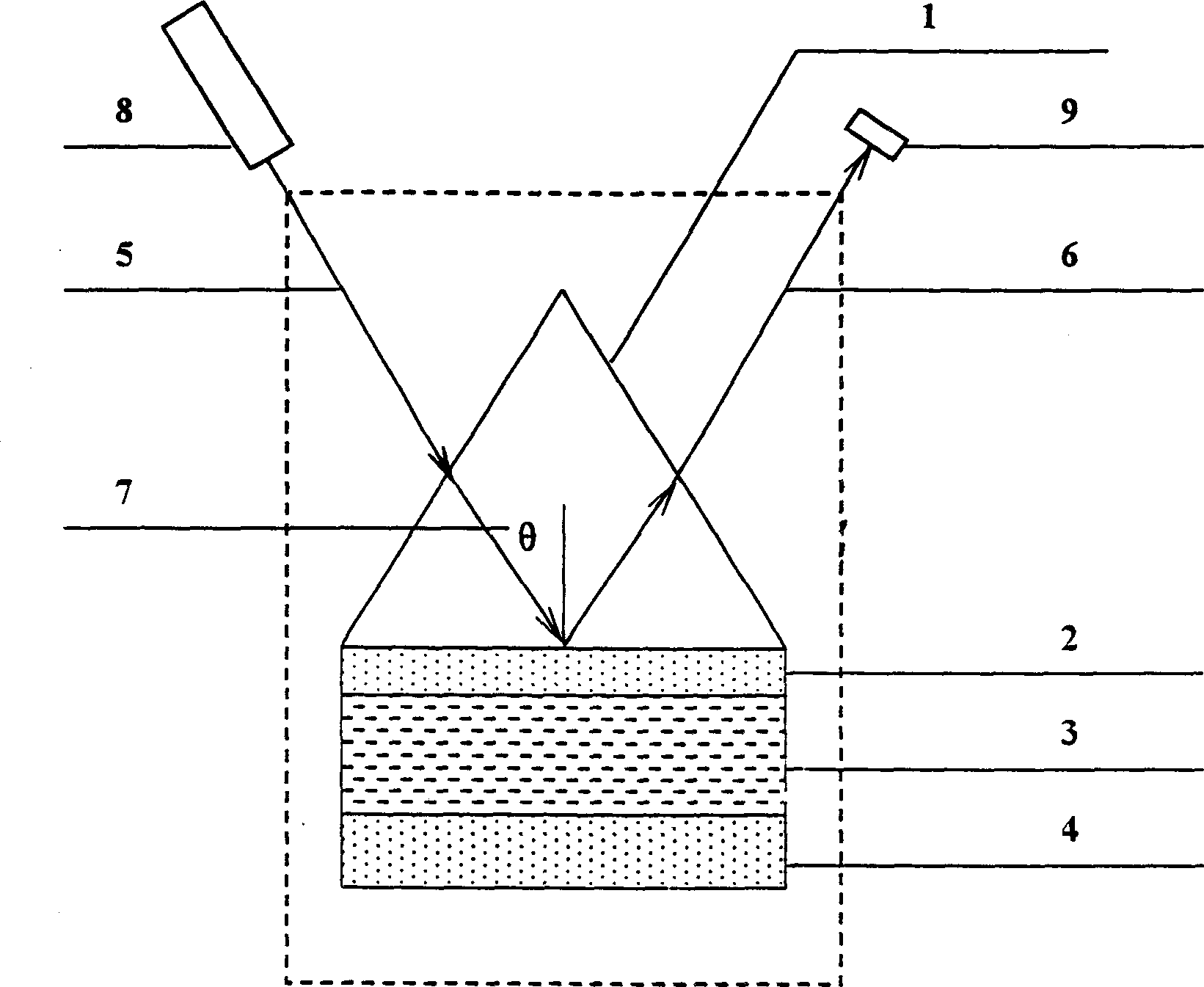

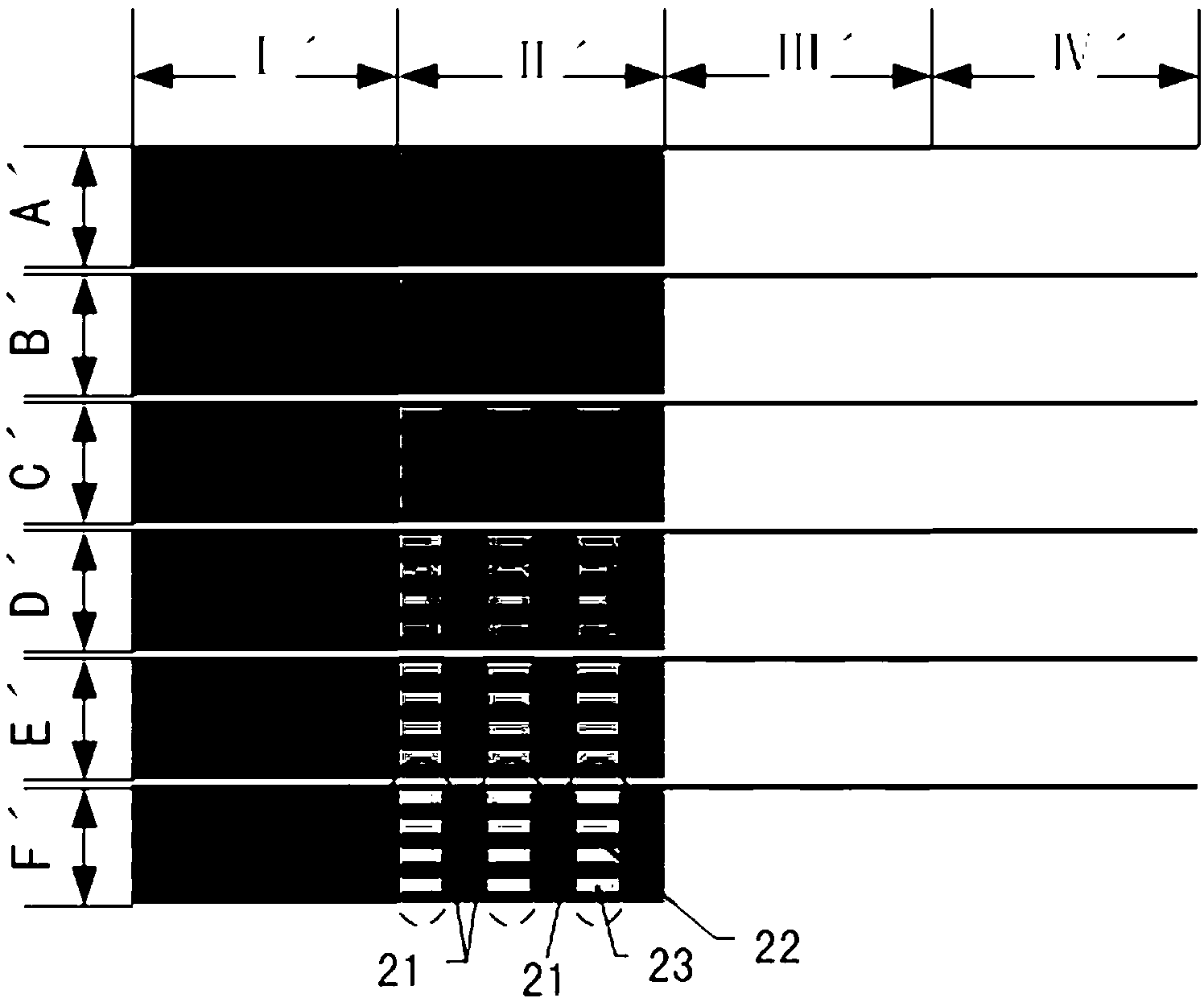

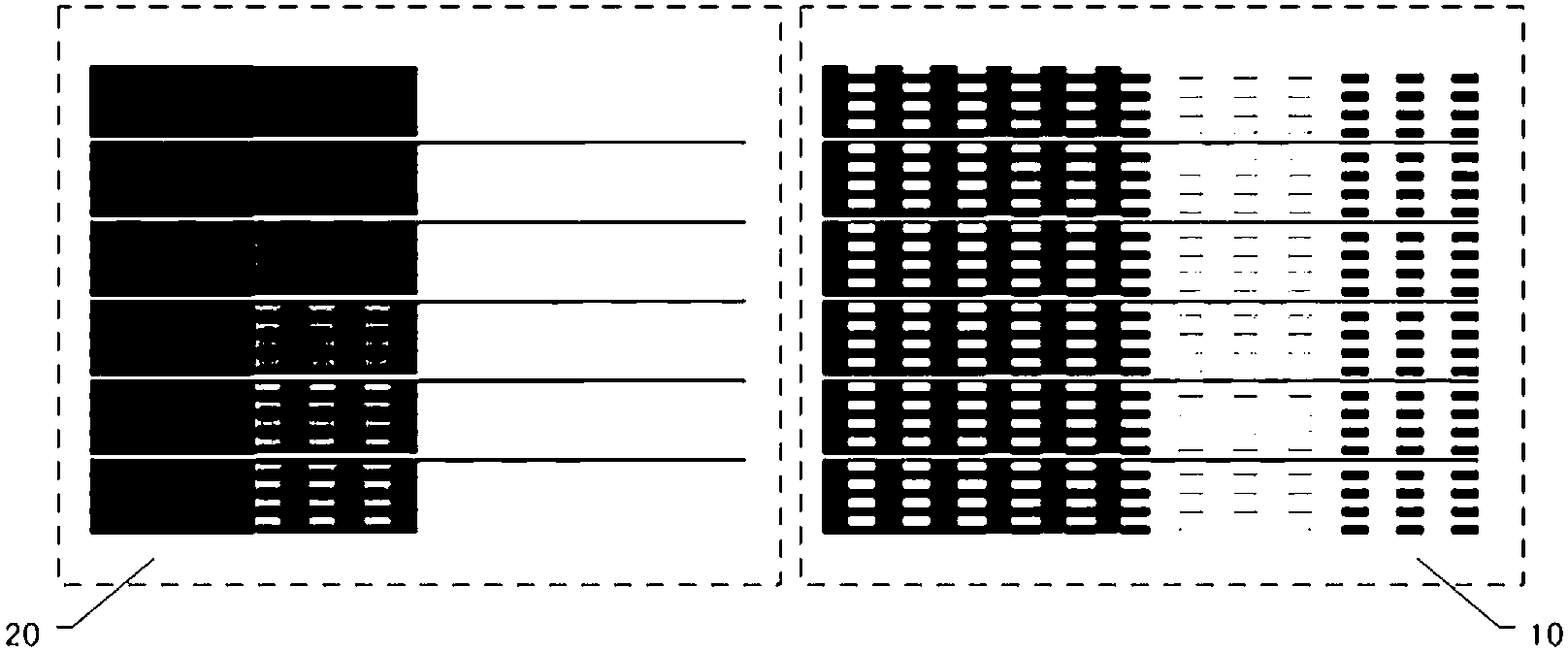

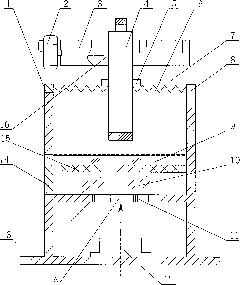

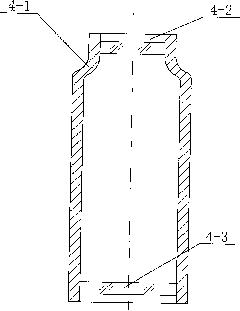

The invention discloses a method for three-dimensionally reestablishing a surface contour of a human body, and the method is characterized by comprising the following steps: (1) the projection region of a protector, the shooting region of a camera and the measured part of the human body are corresponding; (2) the projector projects one image once, the camera collects one image, and the projected image comprises black and white images, Gray code images and phase shift grating images; and (3) the collected pictures are processed to obtain the three-dimensional information of the surface contour of the human body. In the invention, a phase error compensation curve is designed and the reestablishment accuracy of the surface contour of the human body is enhanced according to the characteristics of the projector and the time characteristics in the projecting and shooting courses; a common period calibration method is improved and used for calibrating the absolute phase of the surface contour of the human body, thereby enhancing the reestablishment accuracy of the surface contour of the human body; and an independent projected image generating module is adopted and used for generating the projected images and controlling the projected images of the projector, thereby facilitating the control on the time interval between the projected images of the projector and the collected images of the camera and enhancing the stability of phase error fitted functions.

Owner:SOUTHEAST UNIV

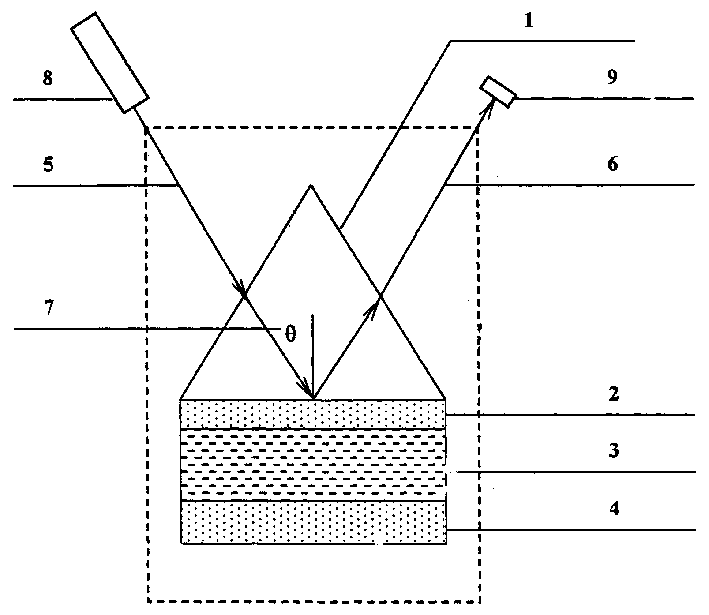

Dual-surface metal waveguide measuring method and its device

InactiveCN1396445ACancel noiseSimple methodScattering properties measurementsInvestigating moving sheetsFilm materialRefractive index

A device for measuring dual-surface metal waveguide is composed of a coupler, an upper metal membrane, the film layer to be measured, and a lower metal membrane. The film layer to be measured and the two metal membranes are of dual-surface metal waveguide structure with the upper and lower metal membranes as upper and lower cover layers for wave guide, and so the light is mainly transmitted in the film layer to be measured. Its method includes such steps as preparing the device by evaporation plating, sputtering, or other methods, selecting the wavelength, incident angle and polarizing mode of laser, receiving and recording the laser intensity, changing the incident angles to obtain the laser intensity-incident angle curve, finding out the resonant angle, width and depth of absorption peak, and calculating refractivity and thickness of the film material.

Owner:SHANGHAI JIAO TONG UNIV

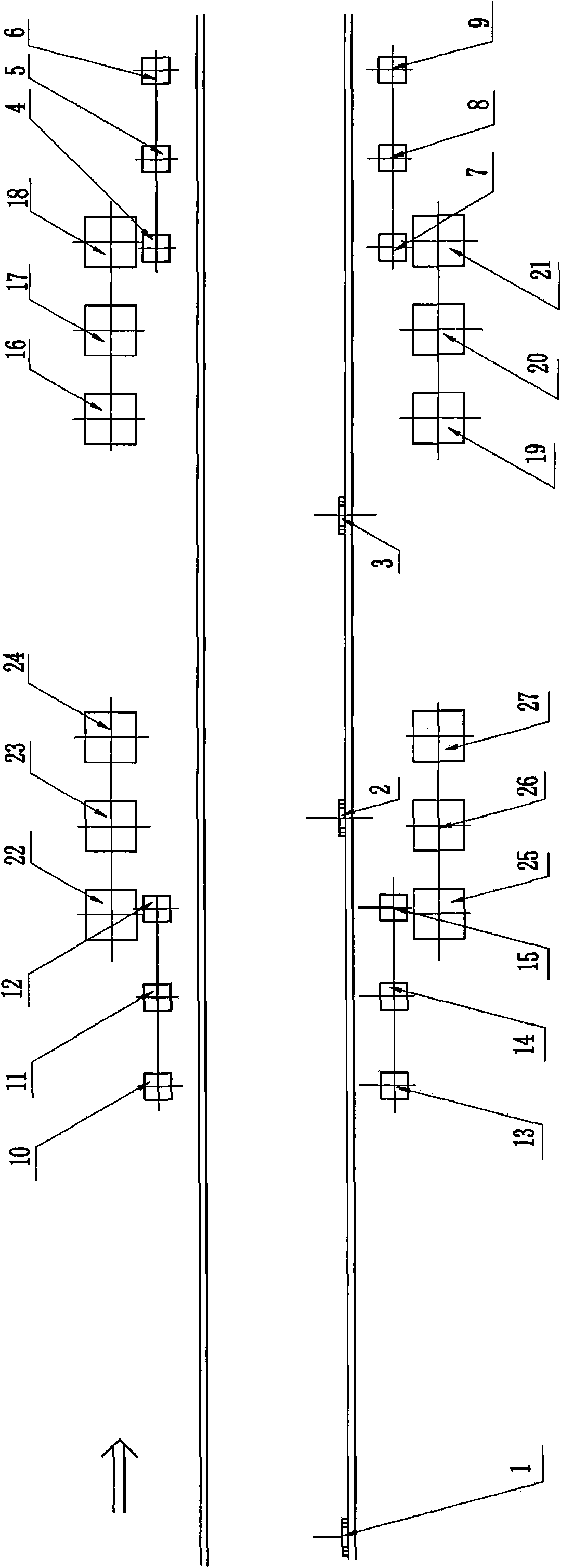

Railway wheel tread scratch image dynamic detection device

InactiveCN101913367AEasy to judgeEasy to handleWheel-rims surveying/measuringOptically investigating flaws/contaminationRailroad wheelPersonal computer

The invention discloses a railway wheel tread scratch image dynamic detection device, belonging to the technical field of machinery detection equipment structure carrying out detection on railway (vehicle) wheel tread. The detection device comprises a plurality of scratch detection camera cases provided with built-in camera, a wheel positioning system, an image acquisition system and a control circuit are utilized, an industrial personal computer is utilized to detect wheel pair image shot by a camera which is fixedly arranged and wheel pair safety state. The device can be used for wheel pair detection on vehicles passing through main line of railway, wheel pair detection when motor train unit is put in storage and wheel pair detection when locomotive is put in storage and can dynamically measure fault state of wheel pair tread of train in normal operation, including wheel faults of scratch, stripping, ground pile and the like, so that overhauling person can timely handle the wheel fault of train and the train is ensured to operate safely.

Owner:北京福斯达轨道交通技术有限公司

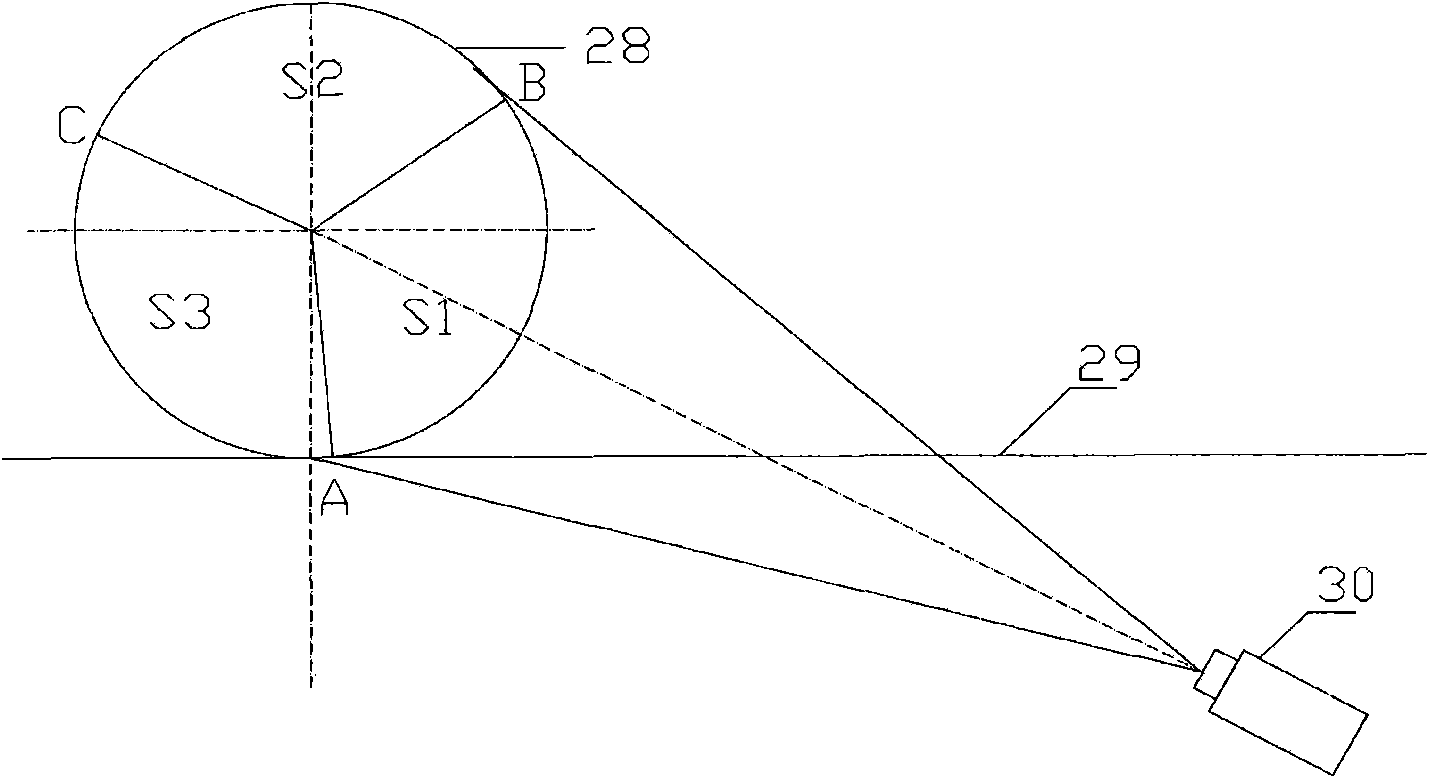

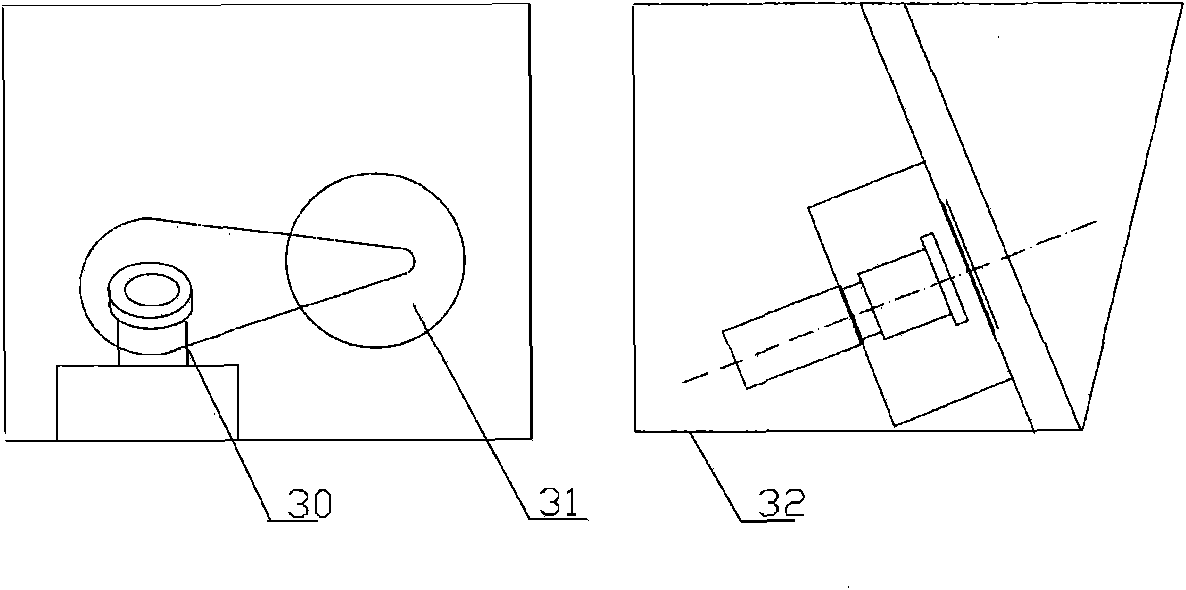

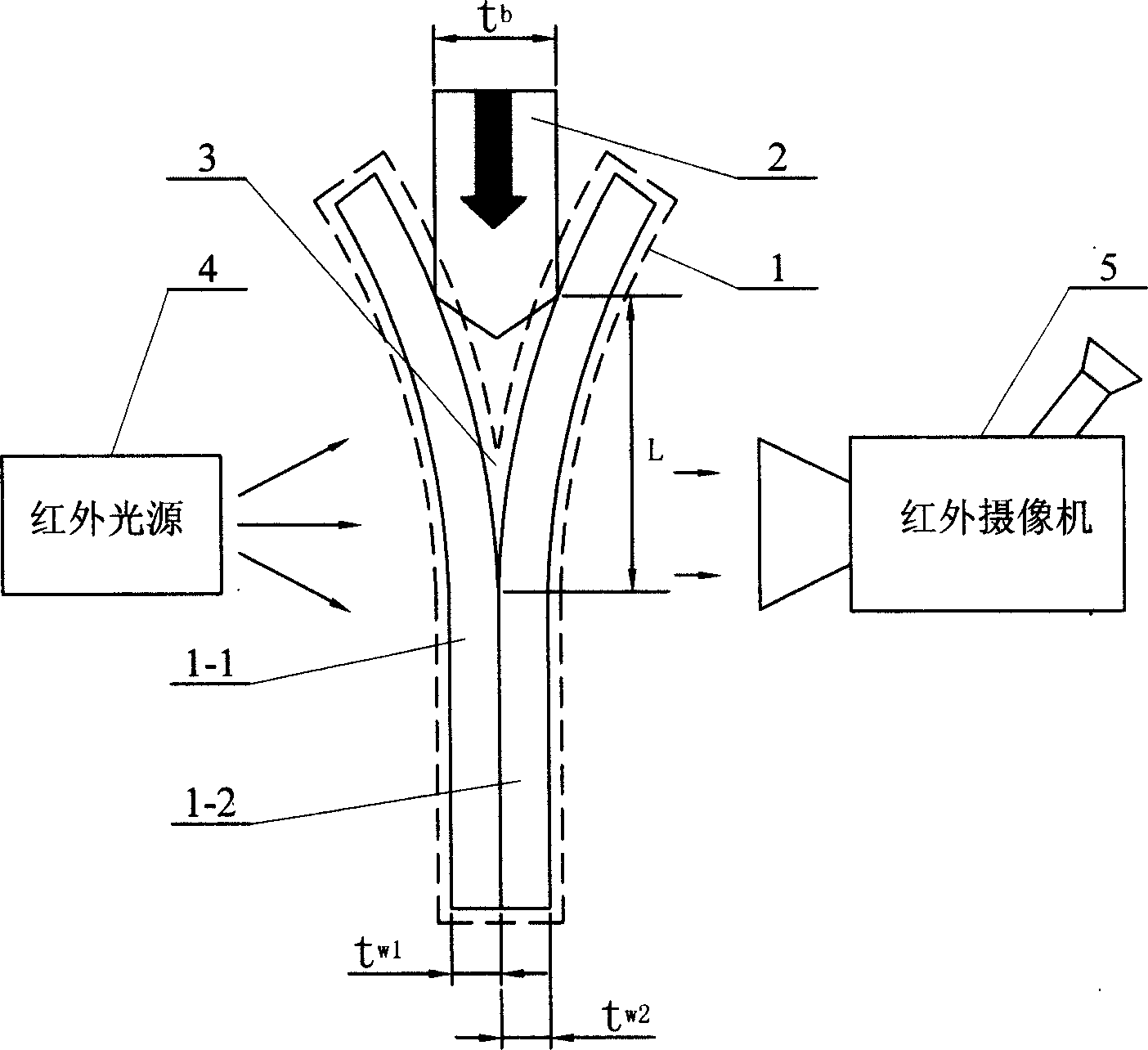

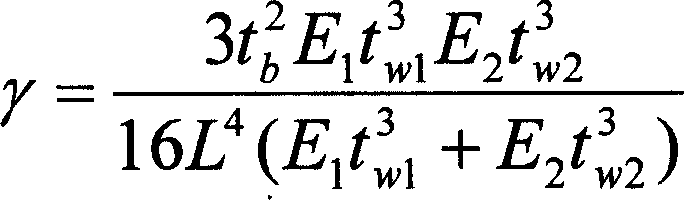

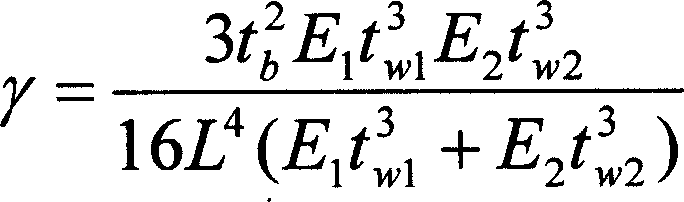

Measuring method for silicon sheet binding strength

InactiveCN1648632AEasy to measureAccurate and reliable measurement resultsUsing mechanical meansUsing optical meansUltimate tensile strengthSilicon chip

The present invention relates to measurement technology of material bonding strength. The measurement of silicon chip bonding strength includes the following steps: measuring the thickness of two bonded silicon chips separately; inserting blade of 100-230 micron thickness into the bonding surface of two silicon chips with the edge being inserted into the bonding surface completely to separate two bonded silicon chips partially and the edge line of the blade being parallel to the bonding surface; measuring the length of the separated part between two silicon chips; and calculating the bonding strength based on the principle that the elastic force to separate the bonded chip part and the bonding force in the cracked top are balanced. The present invention completes the quantitative measurement of bonding strength, and measurement method is simple, reliable, relaxed in environment requirement, universal and accurate.

Owner:HARBIN INST OF TECH

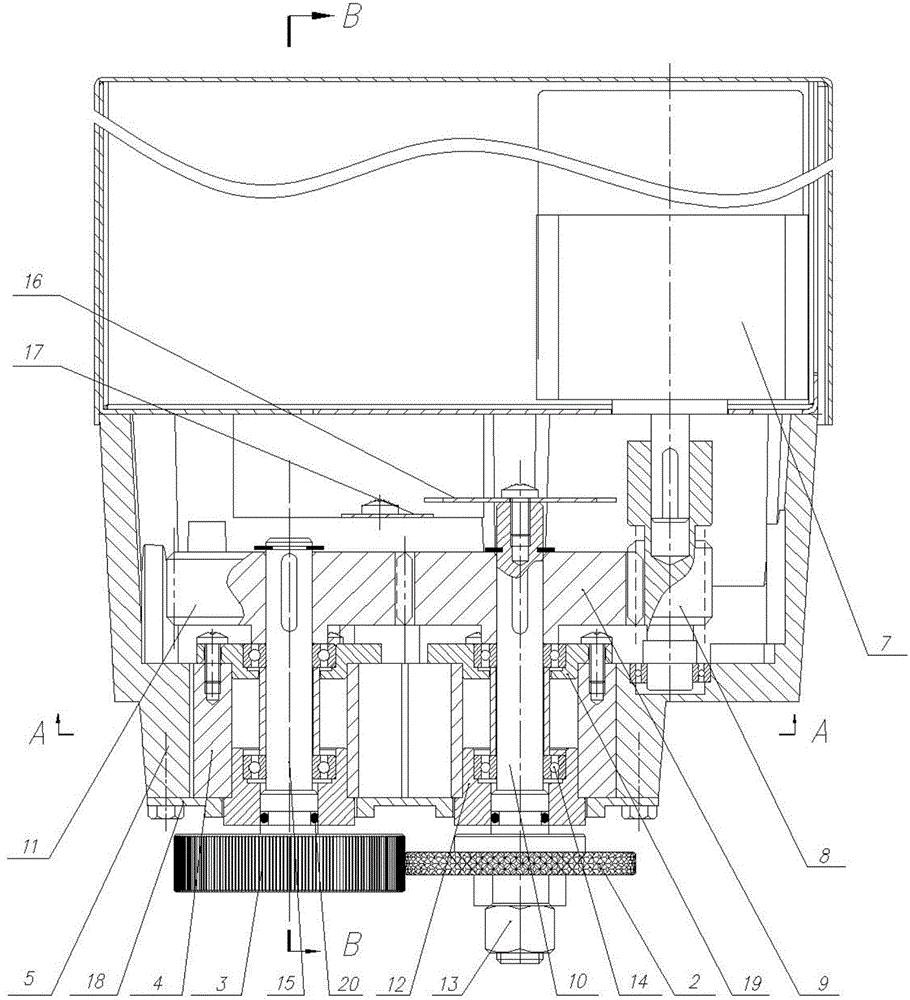

Force measurement type online grain water sensing device

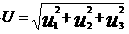

ActiveCN104142358ARealize high-precision measurementReliable deliveryMaterial resistanceEngineeringHardness

The invention discloses a force measurement type online grain water sensing device which comprises a shell, wherein a grain sampling device is arranged in the shell and comprises a force measurement sensor and two roller wheels; the force measurement sensor is fixed in a front opening of the shell, and is used for measuring an extruding force borne by grains between the two roller wheels; the two roller wheels are arranged at the front surface of the force measurement sensor in parallel by two wheel axles, oppositely rotate, and are used for extruding the grains falling between the two roller wheels to deform and transmitting the extruding force to the force measurement sensor; and a power transmission mechanism is arranged in the shell, sequentially connected with the two wheel axles, and used for driving the two wheel axles to oppositely rotate. The force measurement type online grain water sensing device has the beneficial effects that a signal measured by adopting the force measurement type online grain water sensing device is transmitted stably, reliably and accurately without an electric brush; the stability is good, high-precision measurement can be realized; the structure is simple, the process is easy, and the requirements on measured grains and a measurement environment are low; and the detection of water and hardness of the grains can be realized through advanced calibrations of different manners by the sensing device.

Owner:吴新怡

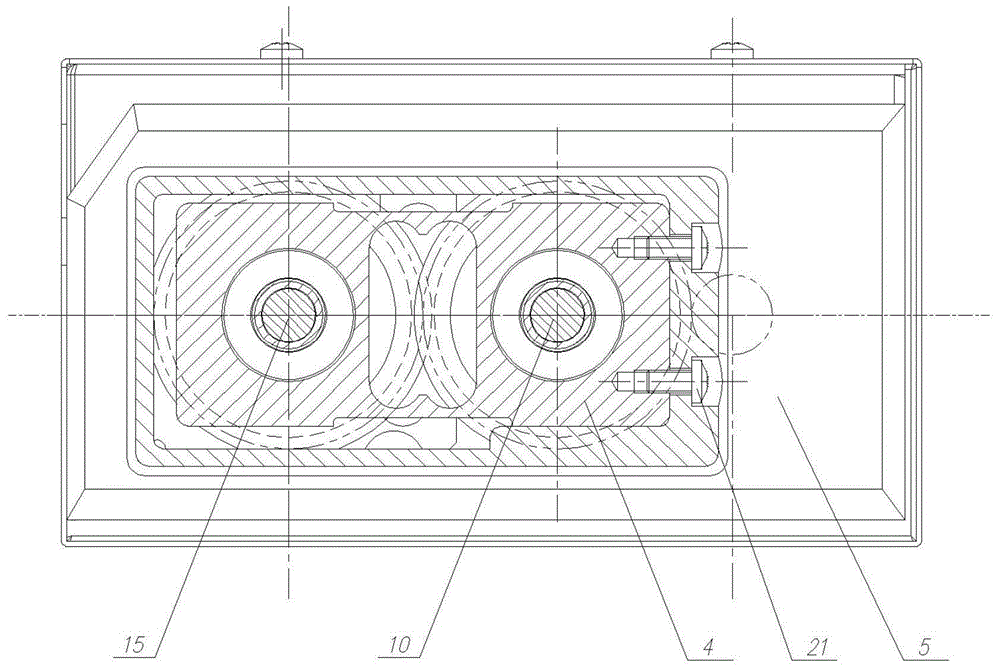

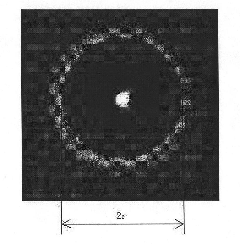

Liquid refractive index CCD real-time measuring device and measuring method

InactiveCN101776572ALow costLow requirements for measurement environmentPhase-affecting property measurementsMeasurement deviceLight spot

The invention relates to a liquid refractive index CCD real-time measuring device, wherein the lower end of the inside of a dark cassette is provided with a luminescent element, a diaphragm with a light-admitting orifice is arranged above the luminescent element on the dark cassette, the upper surface of the diaphragm is provided with flat-plate transmitting glass, the upper surface of the flat transmitting glass is provided with flat-plate image display glass with an upper optical surface and a lower frosted surface, a shading cover is arranged on the left side of the dark cassette, and the upper end of the inside of the dark cassette is provided with a CCD camera which is connected with a computer through a cable. A method which adopts the measuring device to measure the liquid refractive index is as follows: liquid to be measured forms a liquid film between the flat-plate transmitting glass and the flat-plate image display glass, visible light penetrates through the light-admitting orifice, the flat-plate transmitting glass and the liquid film of the liquid to be measured to form a circular dark spot using an incident light spot as the centre of the circle on the frosted surface of the flat-plate image display glass; the CCD camera converts the received circular dark spot to a digital signal to output to the computer through a cable, and the computer calculates the refractive index of the liquid to be measured.

Owner:SHAANXI NORMAL UNIV

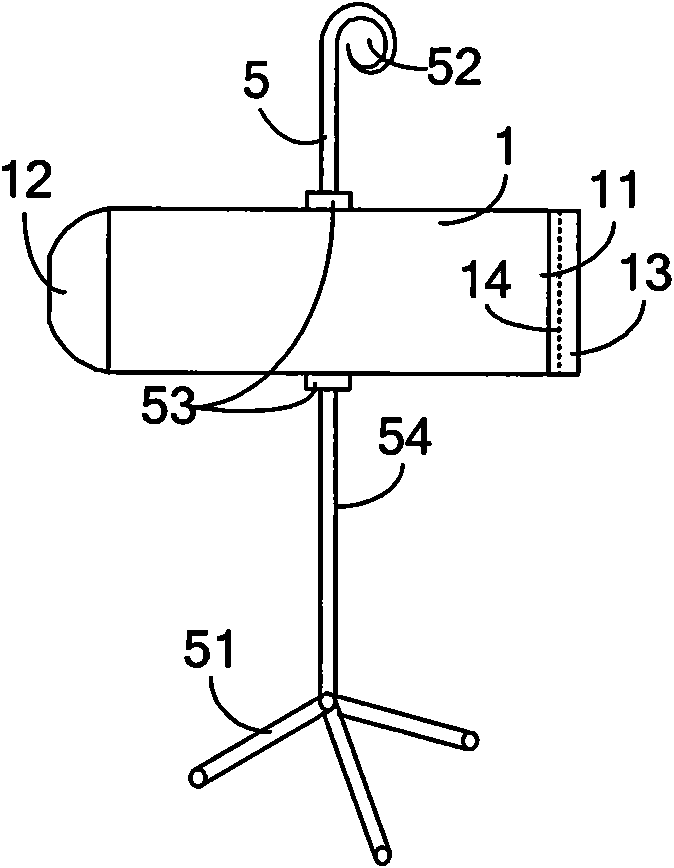

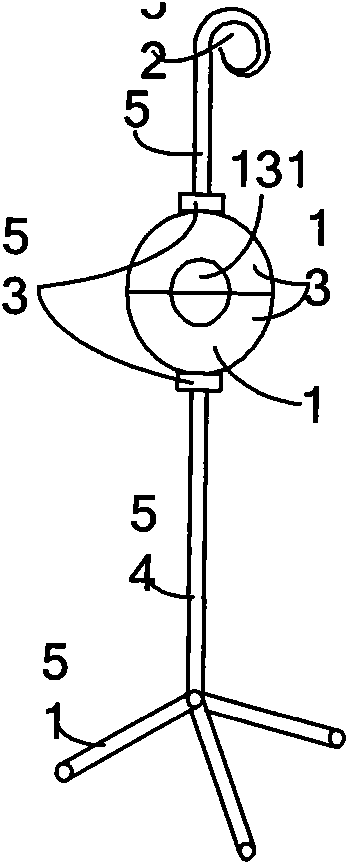

Plant transpiration measuring device

The invention discloses a plant transpiration measuring device. The device comprises an observation room, a condensation system, a water collection measuring component and an exhaust component, wherein the observation room is of a container structure that one end of the observation room is provided with an inlet, while the other end thereof is provided with an outlet; the outlet of the observation room is communicated with one end of a cooling tube of the condensation system; the other end of the cooling tube is communicated with the water collection measuring component; the cooling tube is communicated with the exhaust component; and the bottom of the water collection measuring component is provided with a gravity measuring component. The measuring device not only has the advantages of simple structure, easy manufacturing, convenient carrying, low price and convenient operation and use, but also has excellent measuring effect and can directly measure transpiration water consumption data of plant branches or plants.

Owner:BEIJING FORESTRY UNIVERSITY

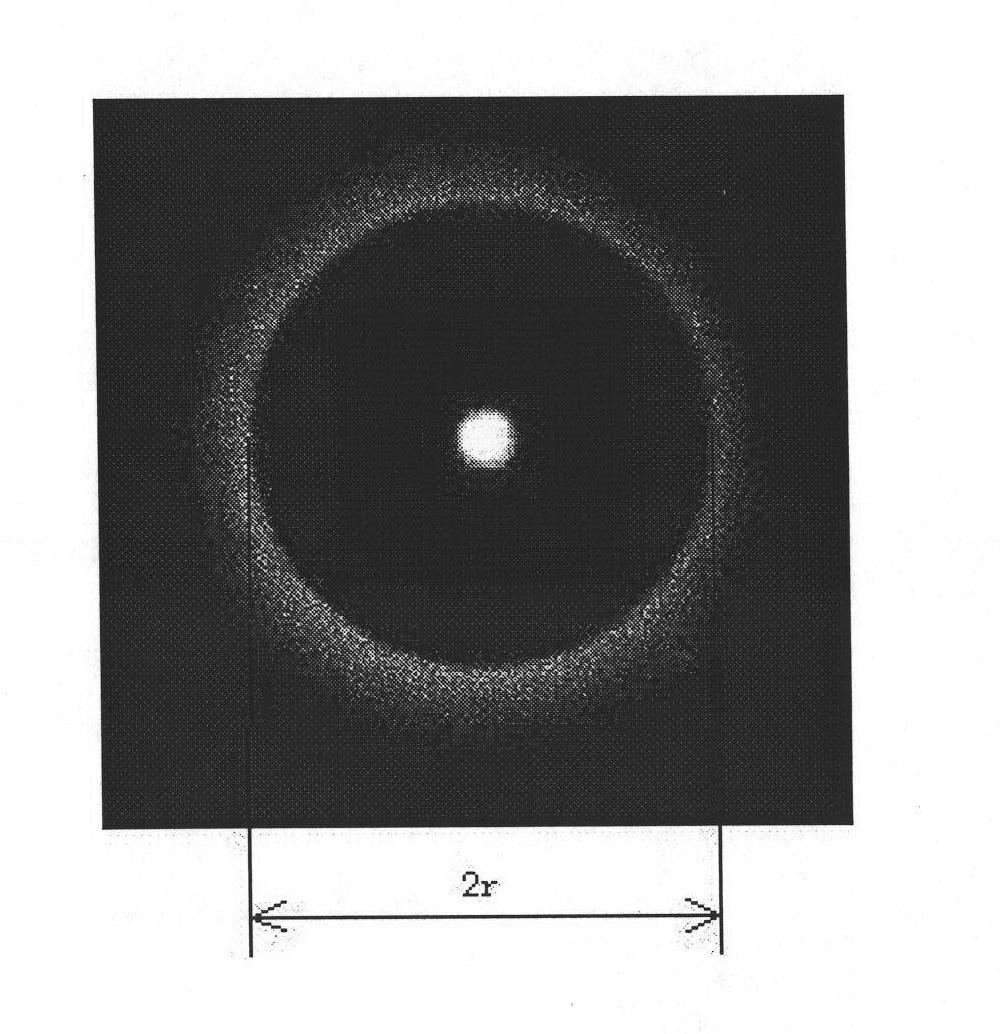

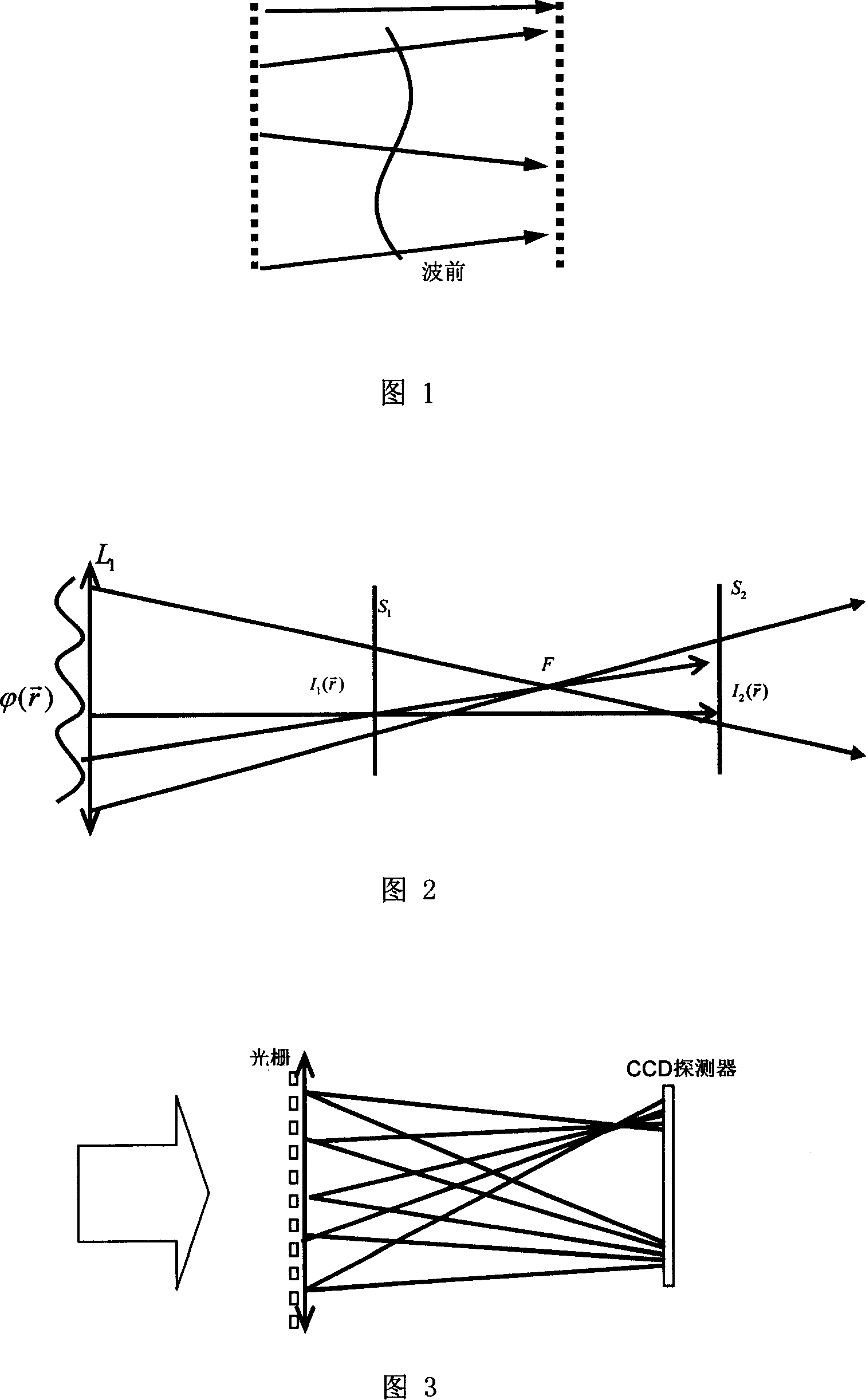

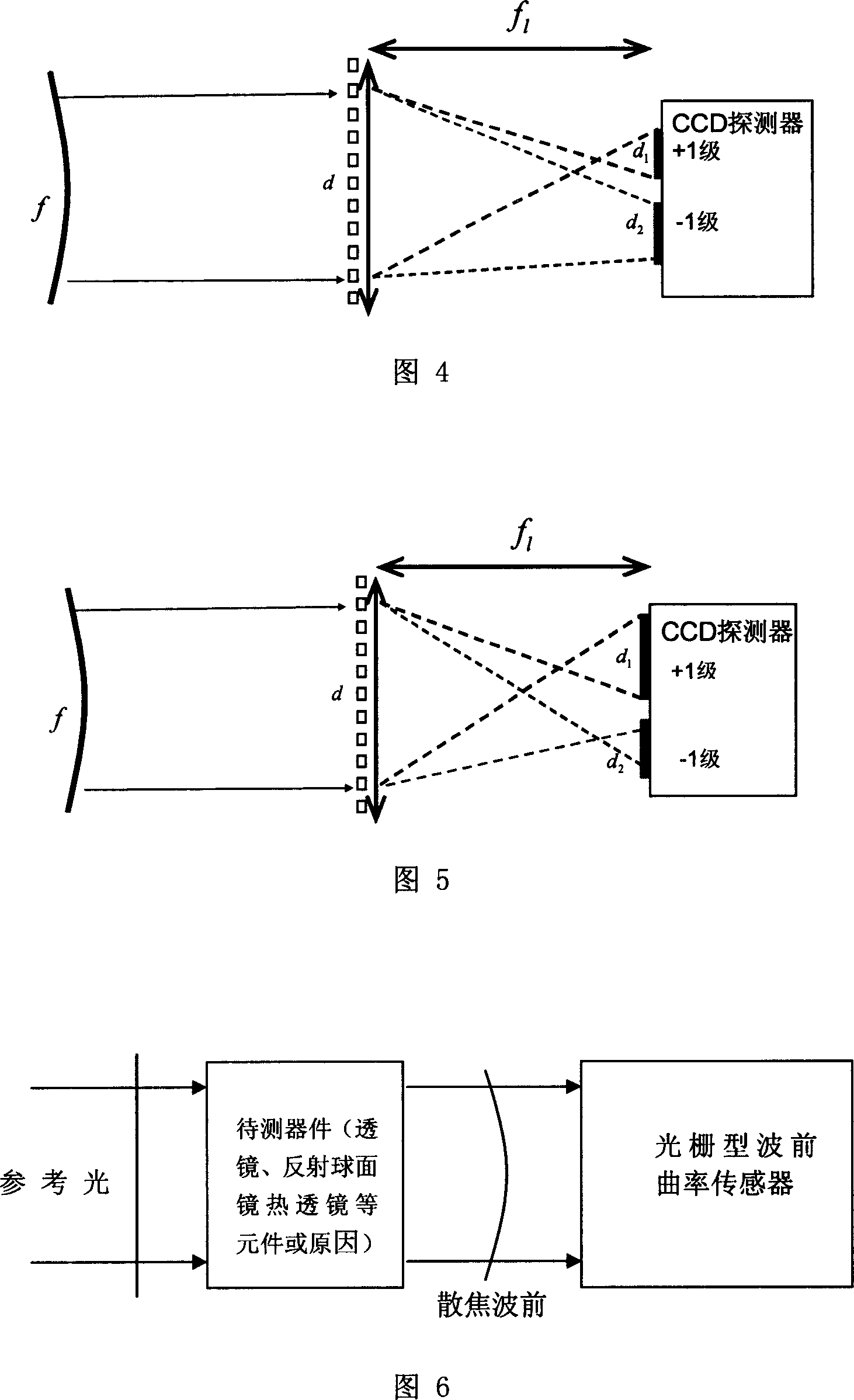

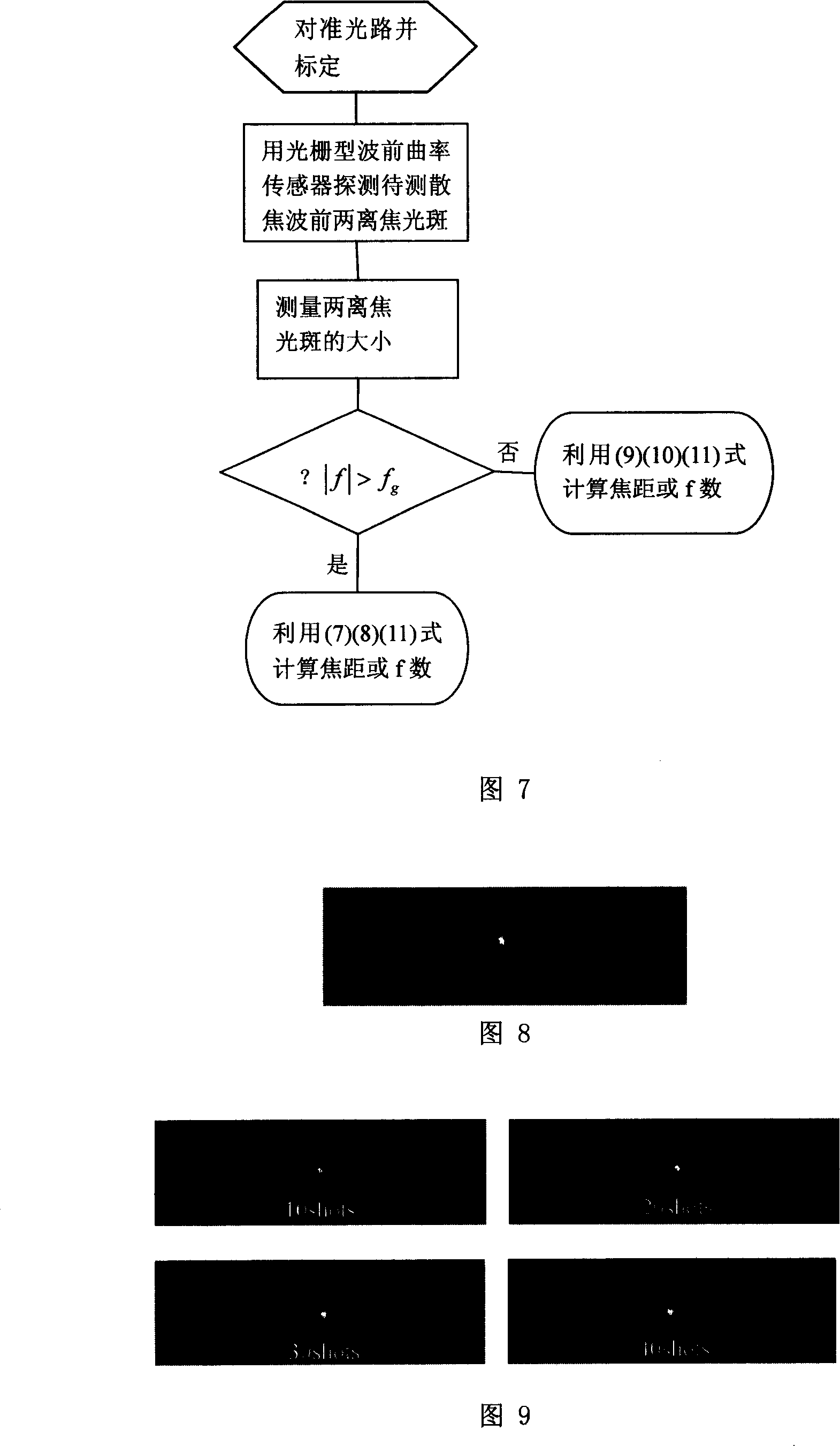

Method for measuring focus and equivalent f coefficient using optical grating type wave-front curvature sensing unit

The invention discloses a method using grating wave front curvature sensor to measure focus and equivalent f number, the steps being: firstly, using reference beam to calibrate the grating wave front curvature sensor; placing the measured device in the optical path, and through the transmission or reflection way to generate the dispersing focus wave front of the measured focus, and the dispersing focus wave front incidents into the grating wave front curvature sensor and using the grating wave front curvature sensor to detect the focus away spot of two focus away surfaces, and measuring diameter d1 of the front focus away spot and the rear focus away spot d2, and according to the grating wave front curvature sensor design parameters, obtaining focus away grating equivalent focal length fg, and the short focal length lens focal length fl; calculating the normalized difference S of the two defocus spot diameter d1 and d2; judging the two defocus spots position relation, and through various formulas, respectively calculating the focal length and equivalent f number. The invention has advantages of high measurement precision, wide application range, and low cost.

Owner:NAT UNIV OF DEFENSE TECH

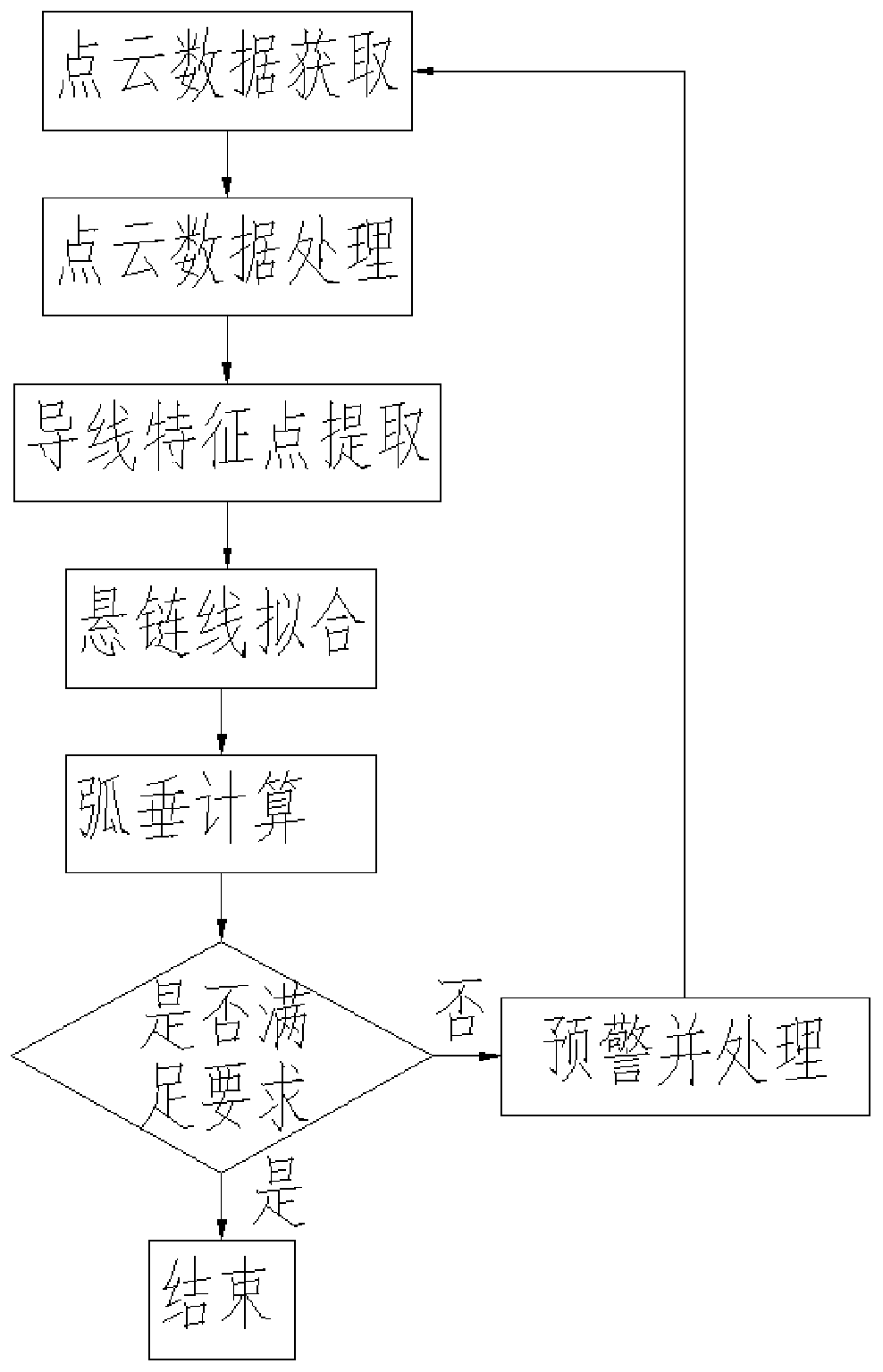

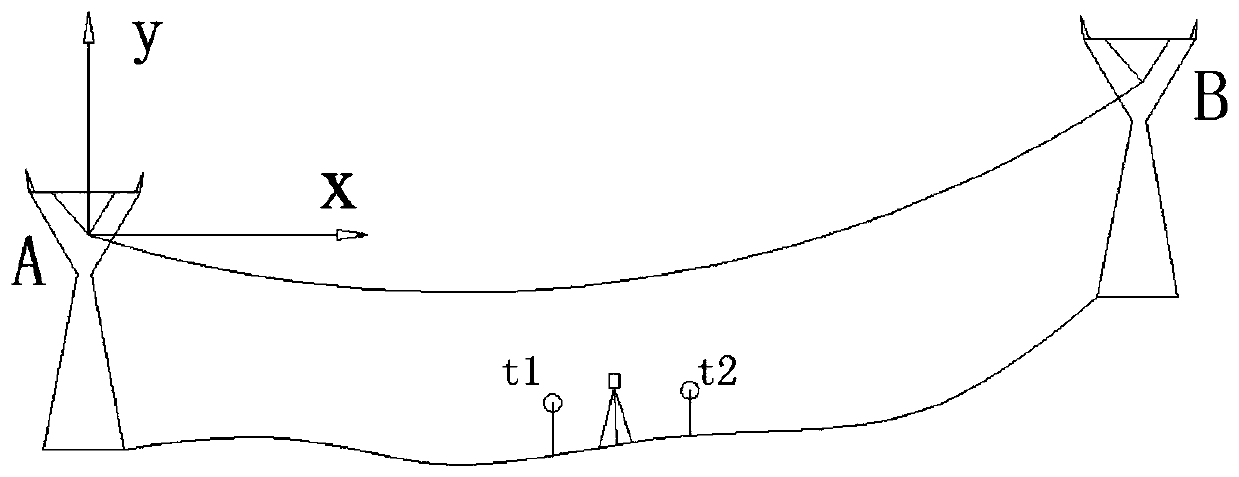

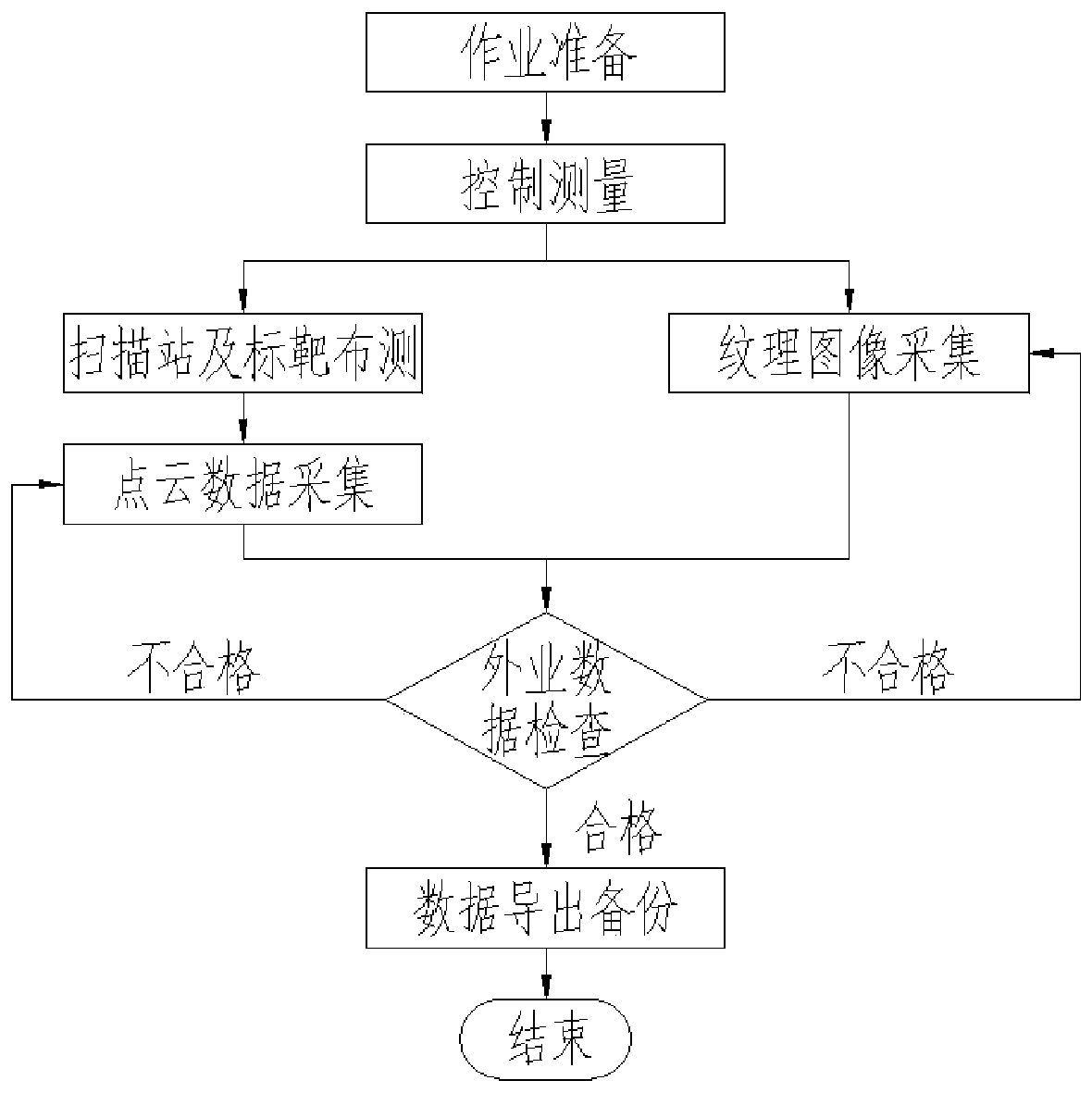

High-precision overhead transmission conductor sag detection method

ActiveCN111121645AAvoiding Mis-Aim SituationsEasy way to work in the fieldUsing optical meansPoint cloudConductor sag

The invention discloses a high-precision overhead transmission conductor sag detection method, and relates to the technical field of metering length, width or thickness by metering equipment characterized by adopting an optical method. The method comprises the following steps: acquiring conductor point cloud data of different instantaneous points of one overhead transmission conductor in a measurement period; performing data processing on the wire point cloud data, establishing a wire coordinate system, and extracting wire feature point data; establishing a catenary equation of the overhead transmission conductor and a sag equation of the overhead transmission conductor based on the conductor coordinate system; and fitting and solving a catenary equation of the overhead transmission line and a sag equation of the overhead transmission line by adopting a nonlinear least square method based on the line feature point data. The method is high in precision, and can calculate the conductor sag at any position.

Owner:内蒙古蒙能建设工程监理有限责任公司

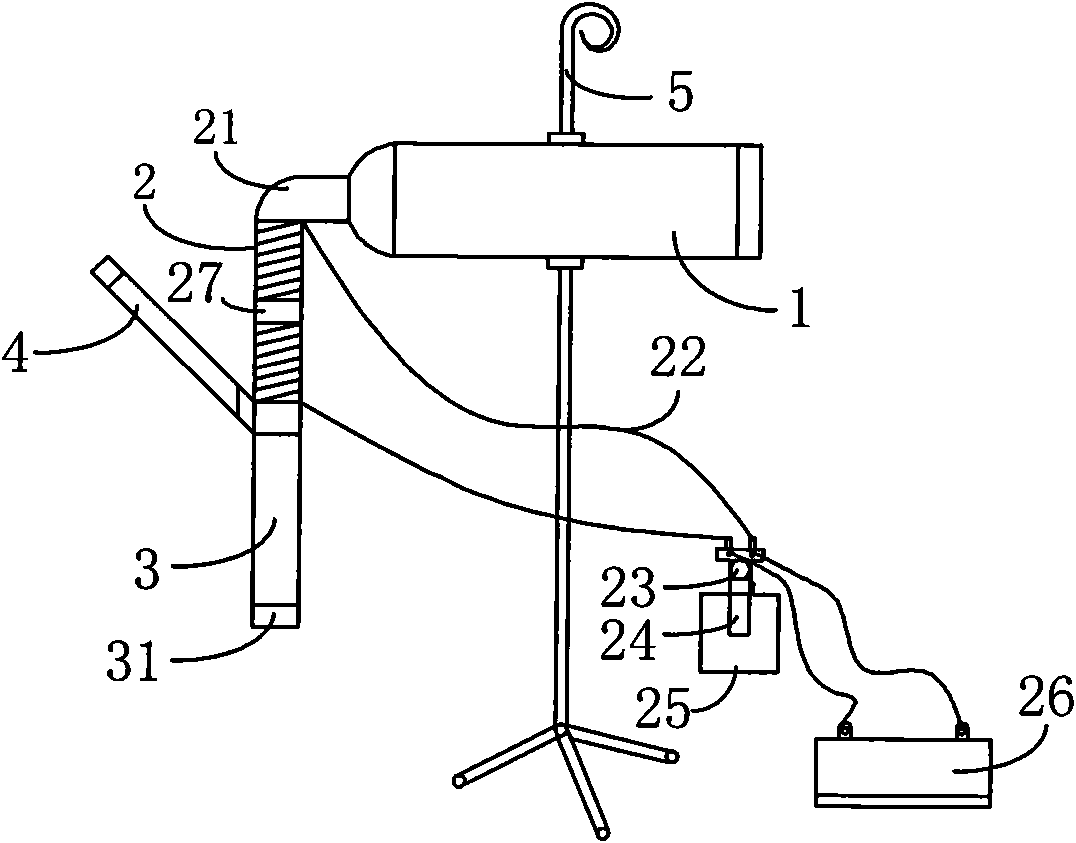

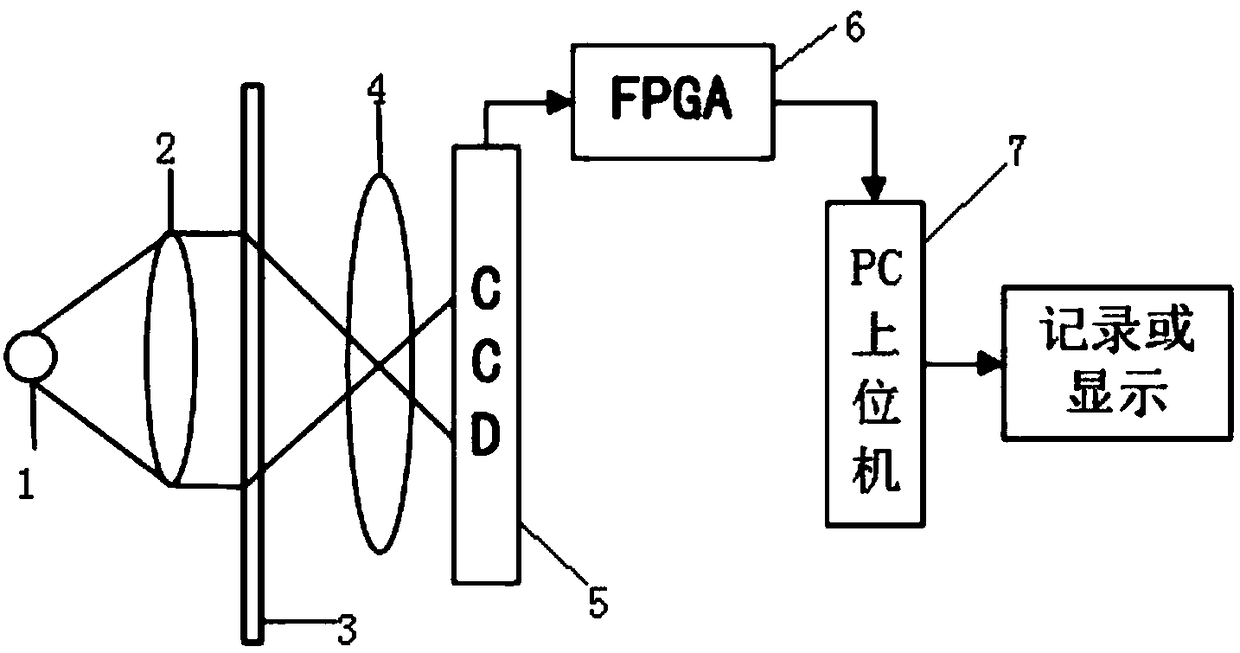

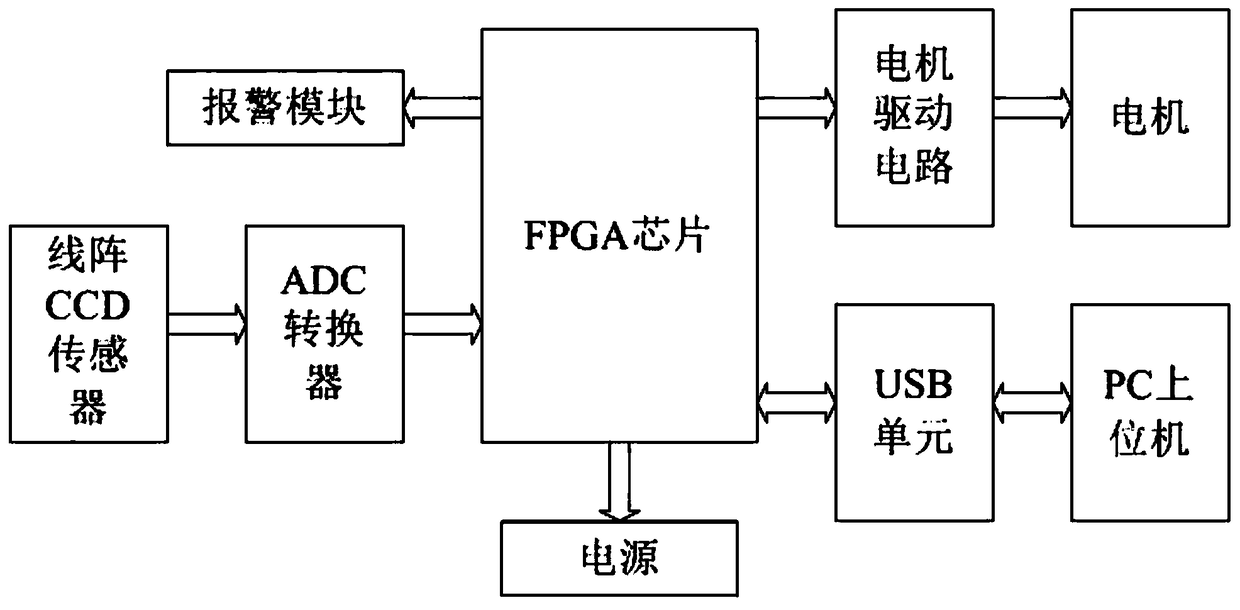

Noncontact yarn tension detection system and method

The invention discloses a noncontact yarn tension detection system and method. The system comprises a yarn guiding wheel, a detection head, an FPGA chip, a power supply and a PC upper computer, wherein the yarn guiding wheel is used for conveying yarns, the detection head is formed by a linear array CCD image collection device, and the power supply is used for supplying power to the FPGA chip; andthe linear array CCD image collection device comprises a parallel light source, a prism, an imaging lens and a linear array CCD sensor, wherein the prism, the imaging lens and the linear array CCD sensor are sequentially located on a passing route of the parallel light source, a shade of the yarn is imaged on the linear array CCD sensor under the irradiation of the parallel light source, the linear array CCD sensor is used for detecting the size change of the shade of the yarn and transmitting a size change signal of the shade into an ADC converter, and the ADC converter is used for converting a received analog signal into a digital signal, transmitting the digital signal into the FPGA chip and calculating a tension value of the yarn. According to the noncontact yarn tension detection system, the tension value of the yarn can be measured in a noncontact manner in the continuous working process of a spinning frame, and compared with an existing contact yarn measurement manner, the precision is relatively high.

Owner:FOSHAN UNIVERSITY

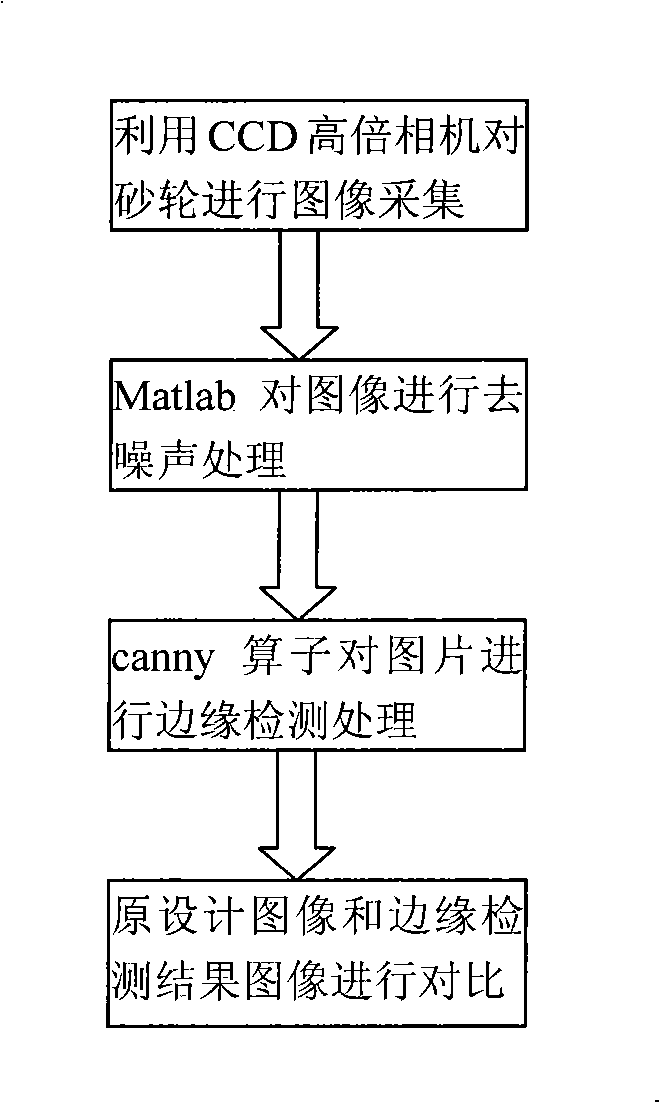

Complicated-type plane metal binder diamond outline detection method

InactiveCN101266140AThe detection process is fastLow requirements for measurement environmentImage enhancementUsing optical meansMATLABGrinding wheel

The invention relates to a diamond outline model detection method of complex surface metal bonding, carrying out image acquisition of wheel grinded aluminum sheet by CCD high-power camera, then denoising the image with matlab algorithm, and performing edge detection of the image with canny operator, finally comparing the design drawing with the image obtained from the edge detection and realizing real-time detecting of grinding wheel truing condition. The invention provides a complex surface metal bonding diamond outline model detection method possessing the characteristics of good rapidity and low cost.

Owner:ZHEJIANG UNIV OF TECH

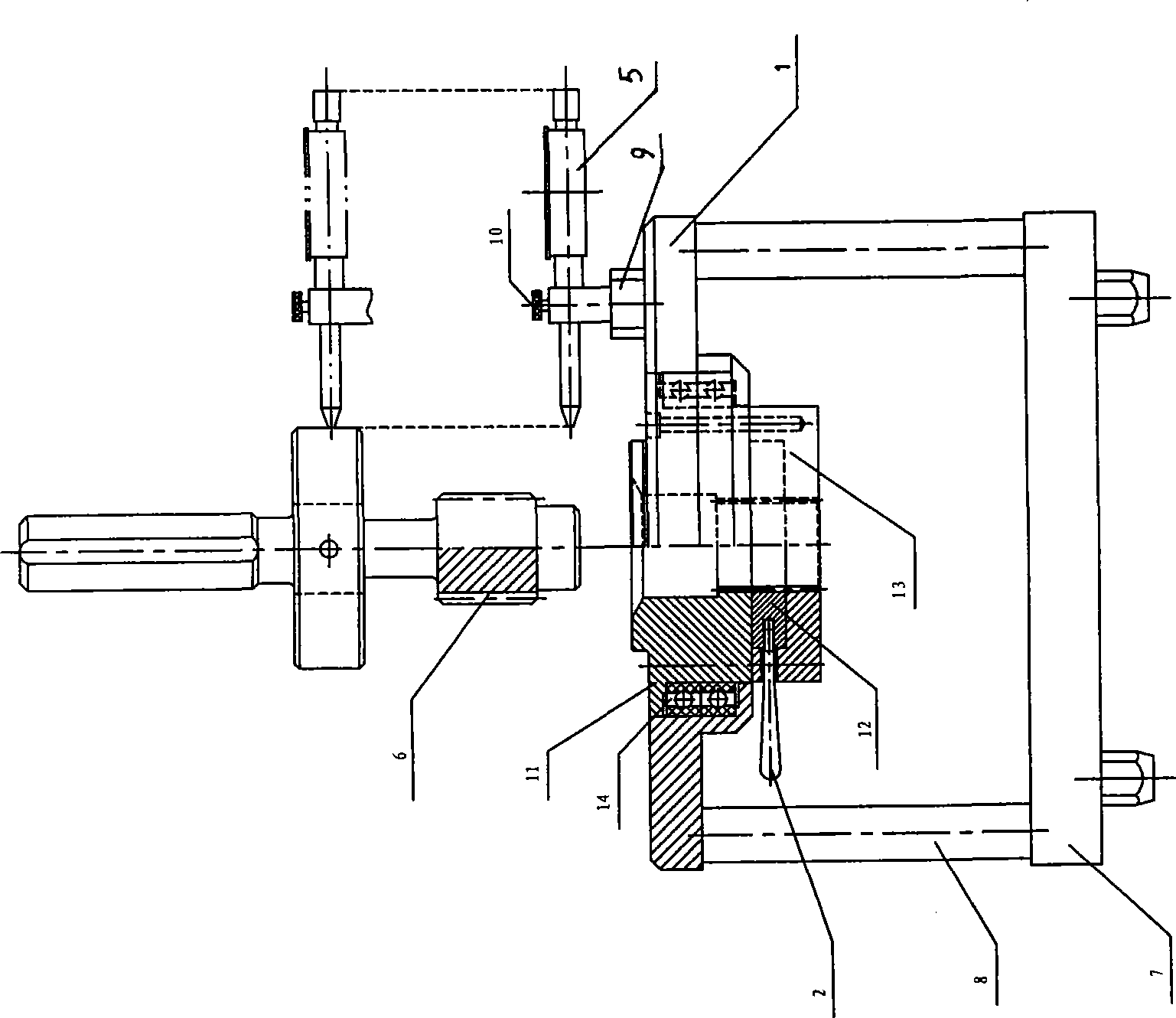

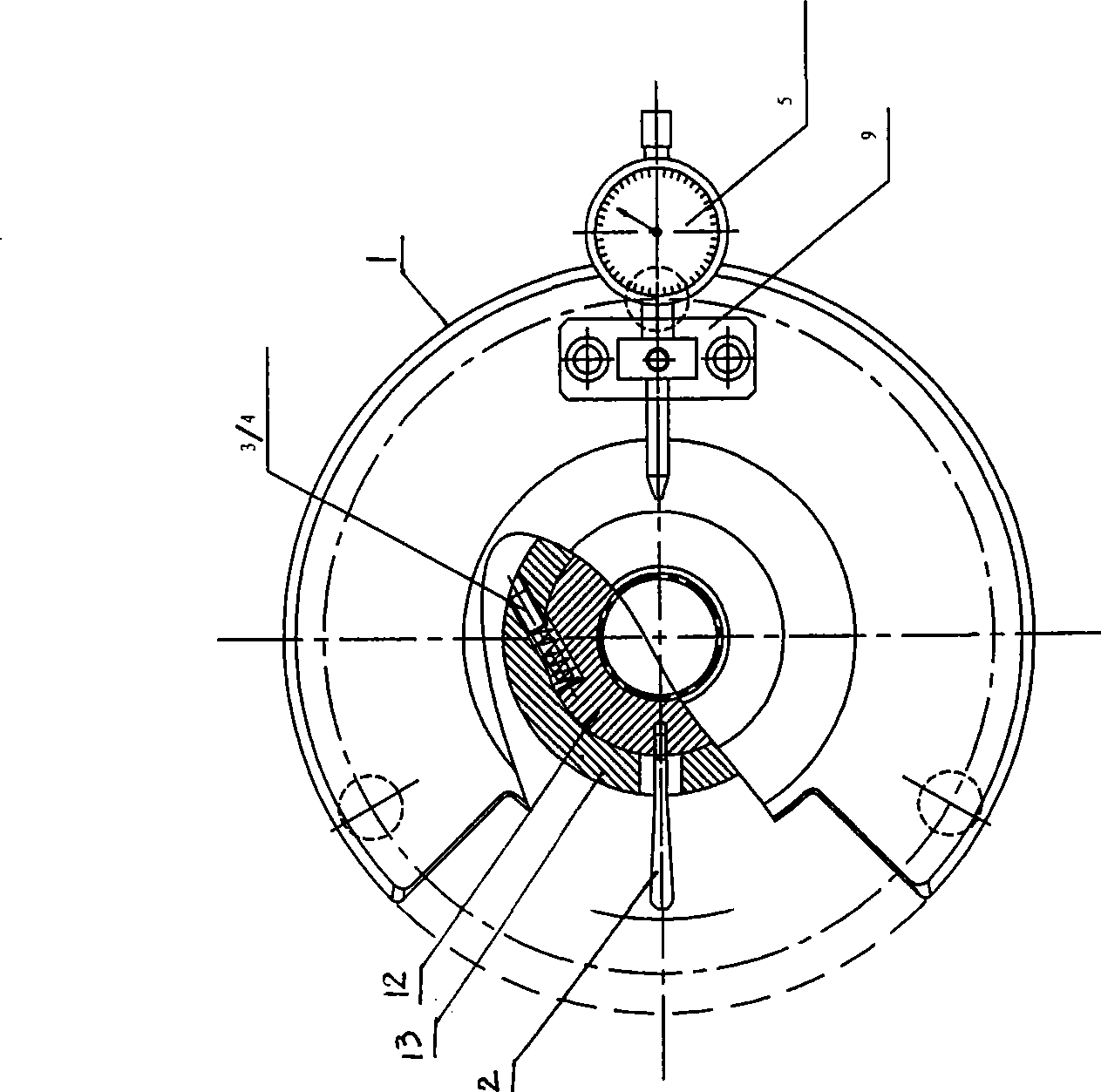

Radial pulsation measurement instrument for external spline gear ring

ActiveCN101476855AGuaranteed rotation accuracyEasy to measureMechanical measuring arrangementsEngineeringField detection

The invention discloses a dial external spline gear ring radial pulsation measuring apparatus, which comprises a measuring stand, an internal spline ring, an adjusting handle, an adjusting screw, a pressure spring and a measuring indicator, wherein the internal spline ring and the measuring indicator are arranged on the measuring stand respectively; the internal spline ring is formed by assembling three coaxial internal splines, namely a first spline, a second spline and a third spline; the first spline and the third spline are fixedly connected with each other and have completely corresponding tooth shape; the second spline is movably connected between the first spline and the third spline and can perform concentric rotation; the adjusting handle is inserted into the second spline and the third spline; and the adjusting screw and the pressure spring are arranged inside concave holes which are arranged inside the second spline and the third spline. The measuring apparatus has the advantages of convenient, accurate and direct measurement, easy maintenance, low requirement on a measuring environment, low cost, high efficiency and the like, and is particularly suitable for mass production field detection.

Owner:EST TOOLS

Box body size measuring method and device, and adhesive tape

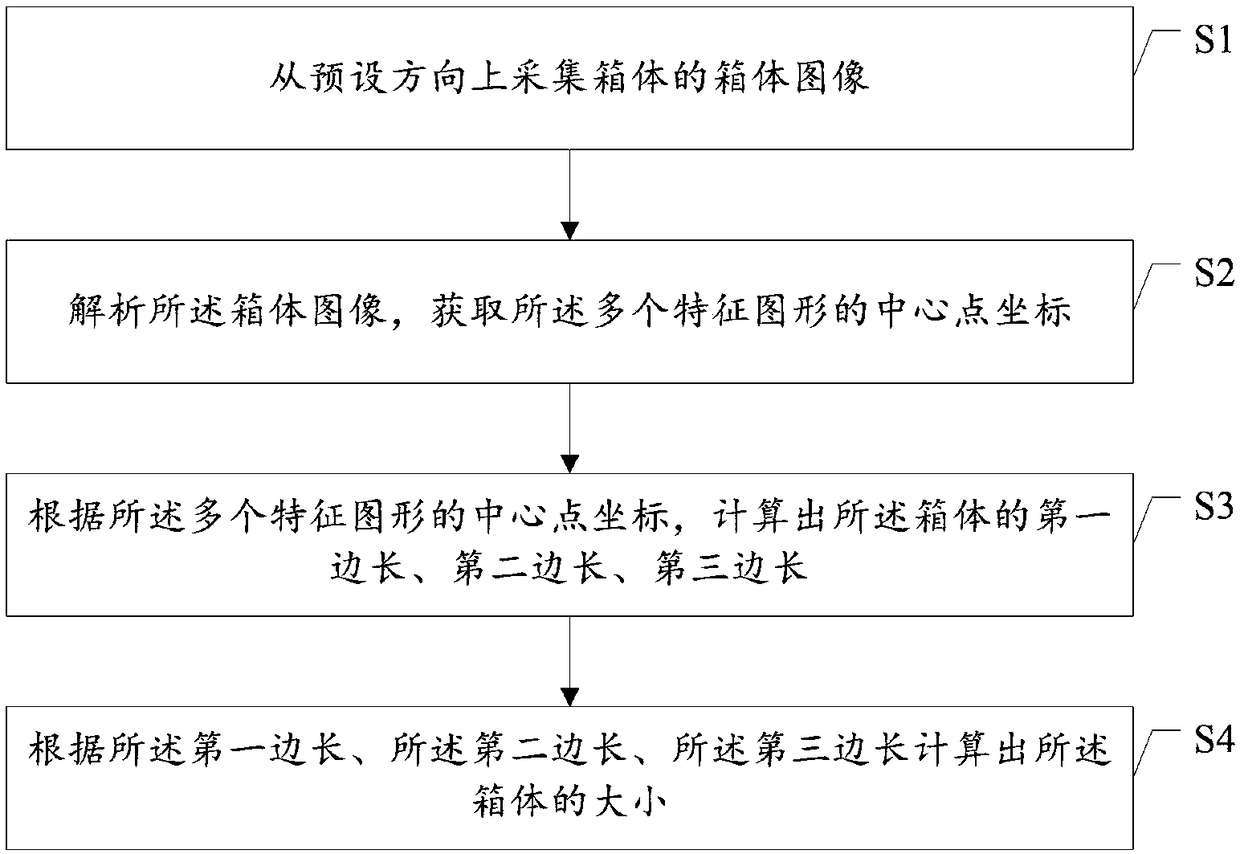

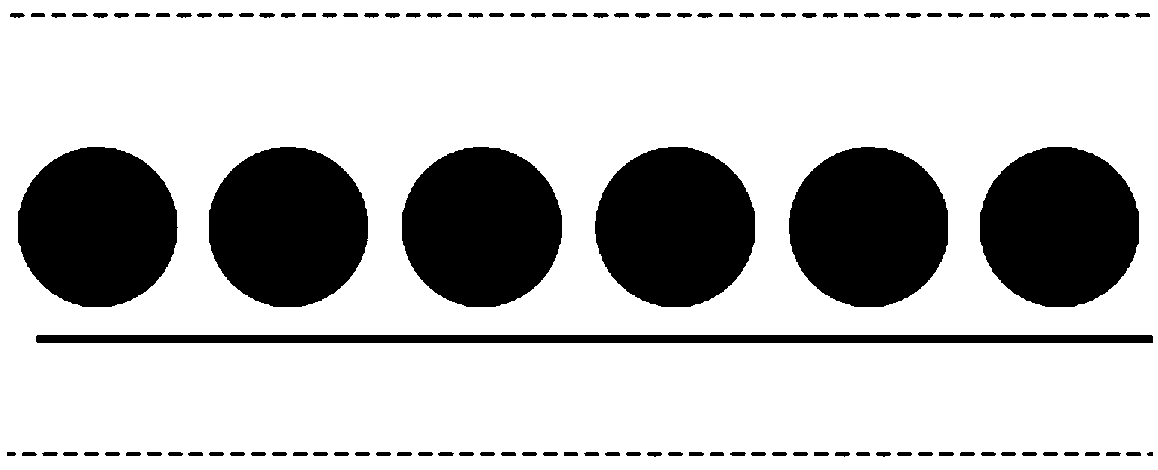

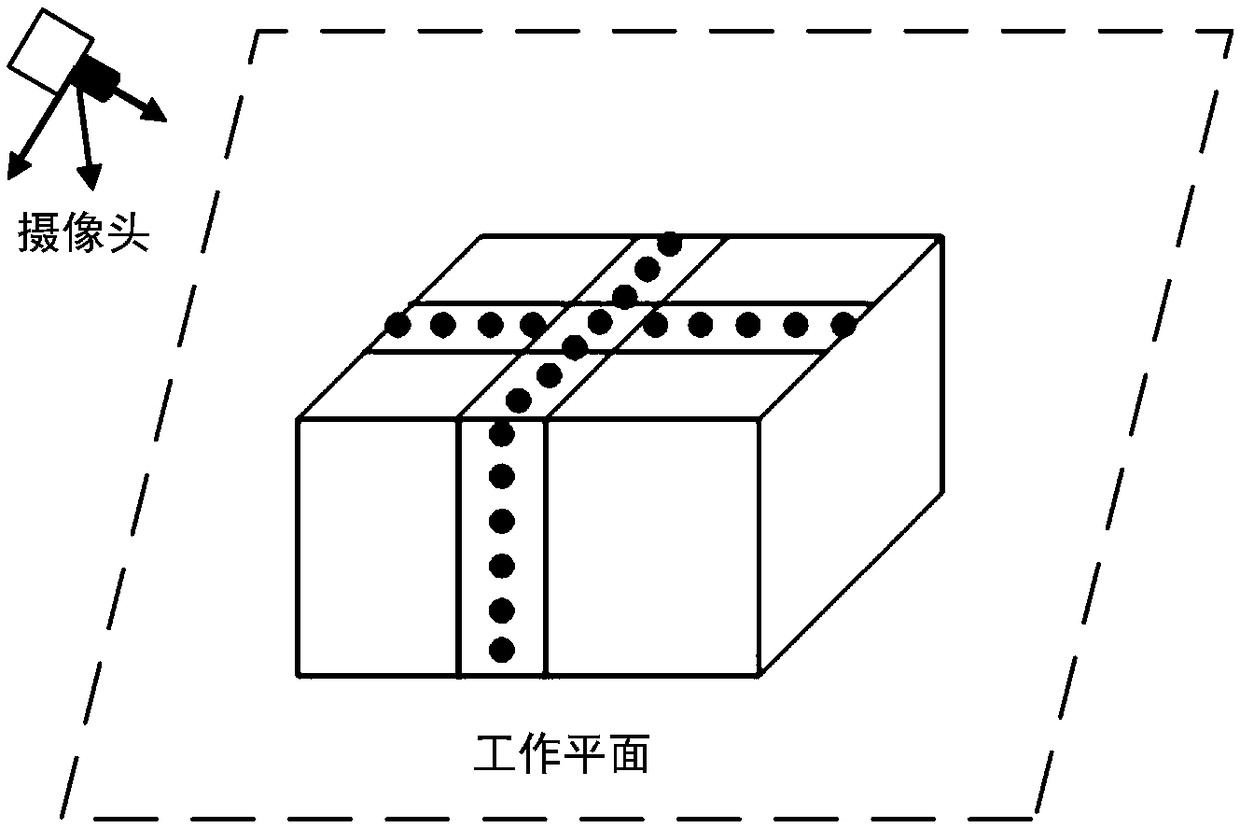

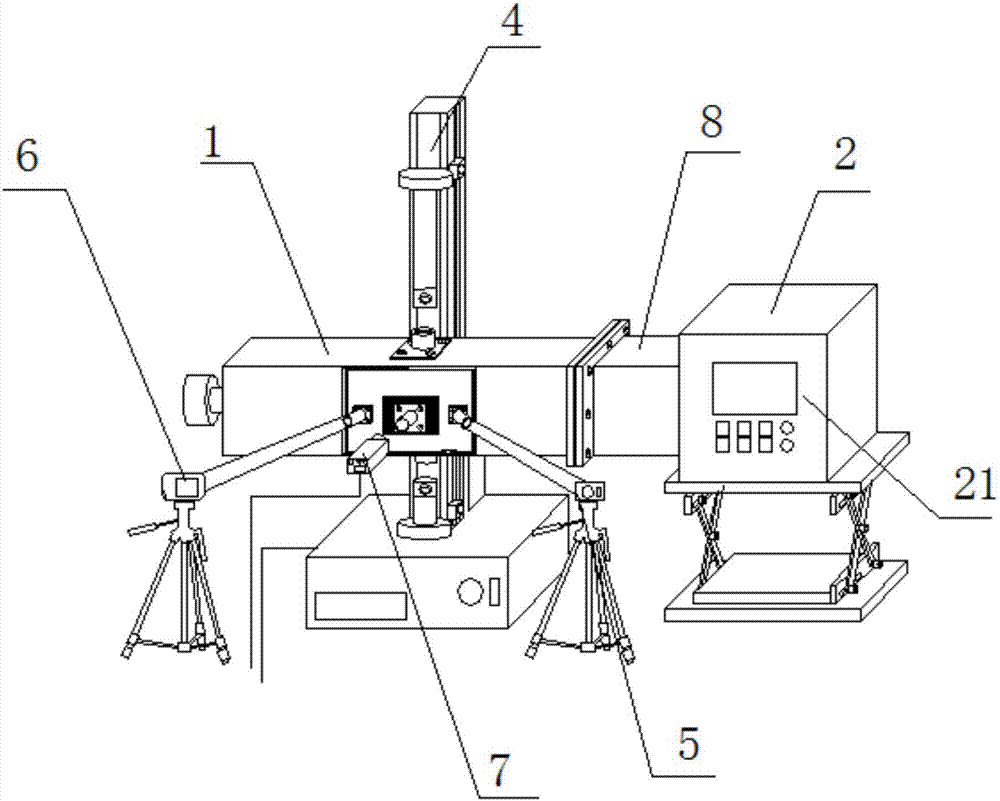

ActiveCN108895961AAccurately measure volumeImprove the efficiency of volume measurementImage analysisUsing optical meansSize measurementBody size

The invention provides a box body size measuring method and device, and an adhesive tape. The box body is provided with an adhesive tape which is wrapped in a preset mode, and the adhesive tape is printed with characteristic patterns which are continuously arranged. The measuring method comprises the steps of S1, acquiring the box body image of the box body in a preset direction, wherein the box body image comprises a plurality of characteristic patterns; S2, analyzing the box body image, and acquiring the coordinates of the center points of the plurality of characteristic patterns; S3. according to the coordinates of the center points of the characteristic patterns, calculating the first side length, the second side length and the third side length of the box body; and S4, according to the first edge length, the second edge length, and the third side length, calculating the size of the box body. According to the invention, the low-cost and high-precision size measurement of the box body is realized.

Owner:NANJING AVATARMIND ROBOT TECH CO LTD

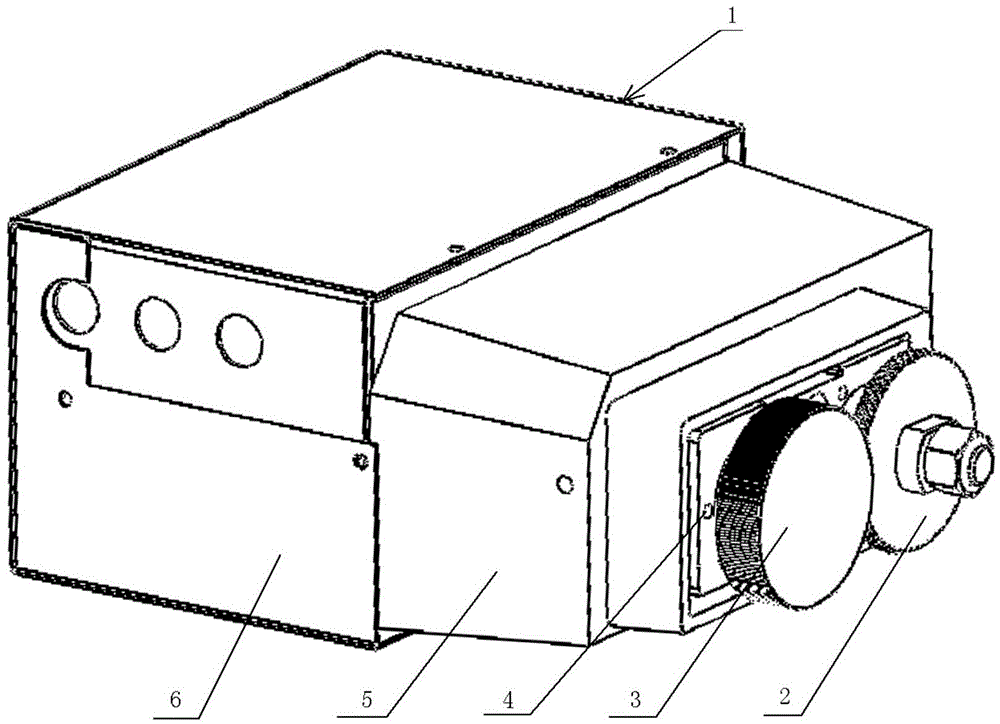

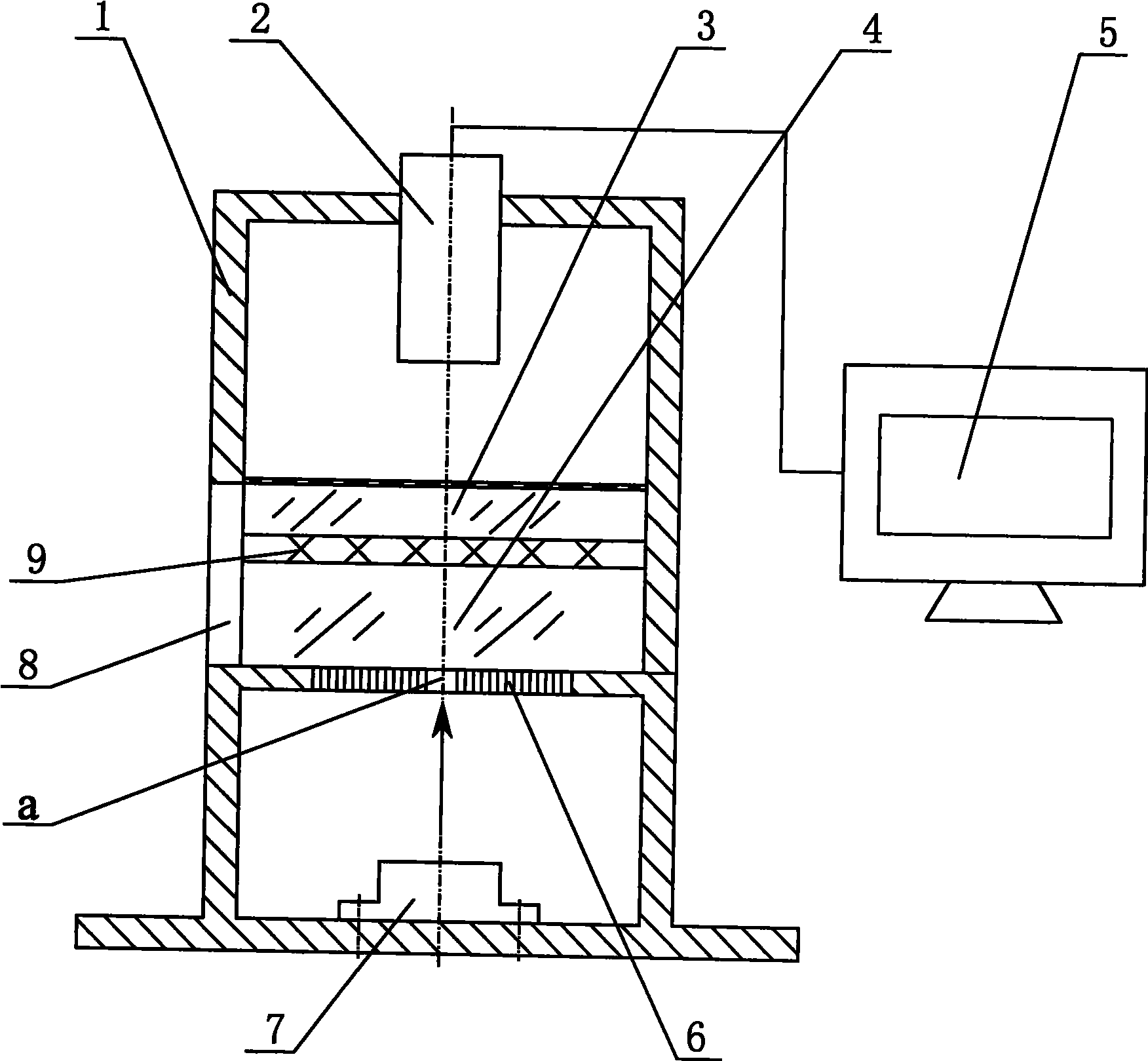

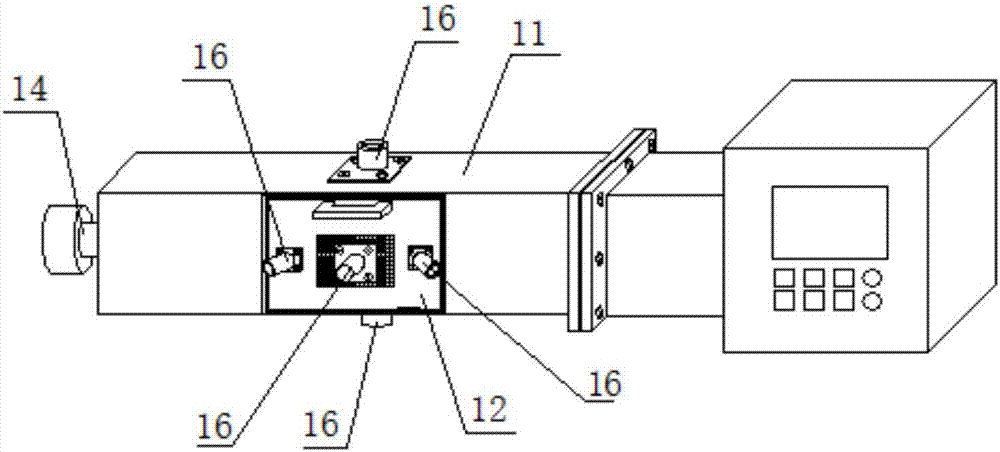

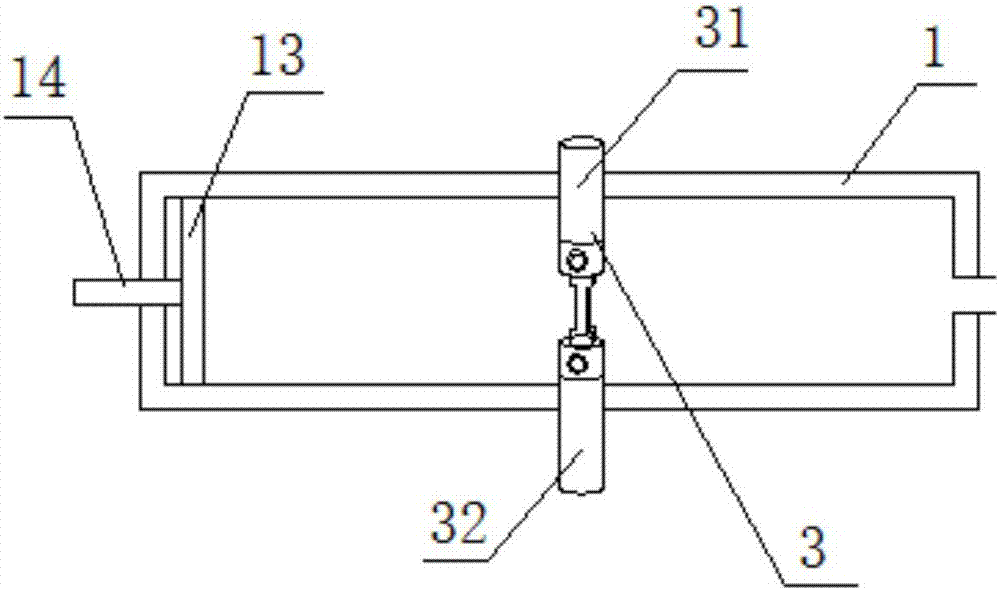

Material performance testing device and material performance testing system

InactiveCN107271294ATo achieve the purpose of supplementary lightGet Full Field DeformationMaterial heat developmentScattering properties measurementsMulti fieldFull field

The invention relates to the technical field of measuring equipment for mechanical properties of materials under force, heat, electromagnetic and other multi-field coupling effect, and in particular relates to a material performance testing device and a material performance testing system. The material performance testing device comprises a heat treatment chamber, a microwave source, a microwave source control module, a holding device for a to-be-tested material, a mechanical loading device, a light source for light supplement, an infrared thermal imager for collection of the surface temperature field of the to-be-tested material and a camera for collection of the speckle image of the to-be-tested material. The material performance testing system includes the material performance testing device, a computer and a mechanical sensor which is arranged on the mechanical loading device; the computer is respectively electrically connected with the mechanical sensor, the infrared thermal imager and the camera. The temperature field and the speckle image of the to-be-tested material under the force, heat, electromagnetic and other multi-field coupling effect can be detected by the material performance testing device and the material performance testing system, further the thermal properties, full field deformation and destruction process of the to-be-tested material can be obtained, and the material performance testing device and the material performance testing system are highly intelligent.

Owner:TAIYUAN UNIV OF TECH

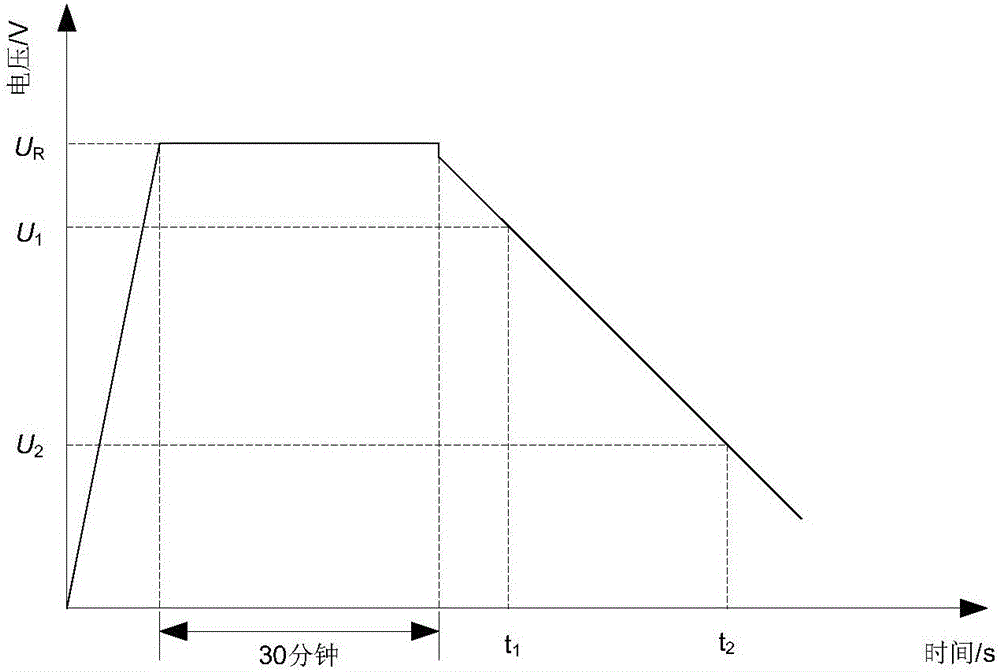

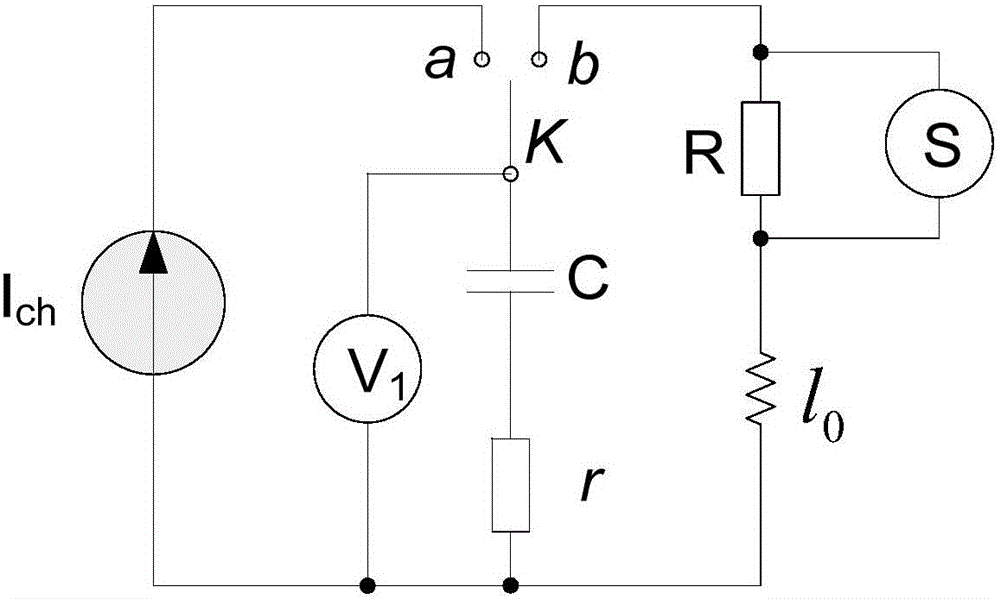

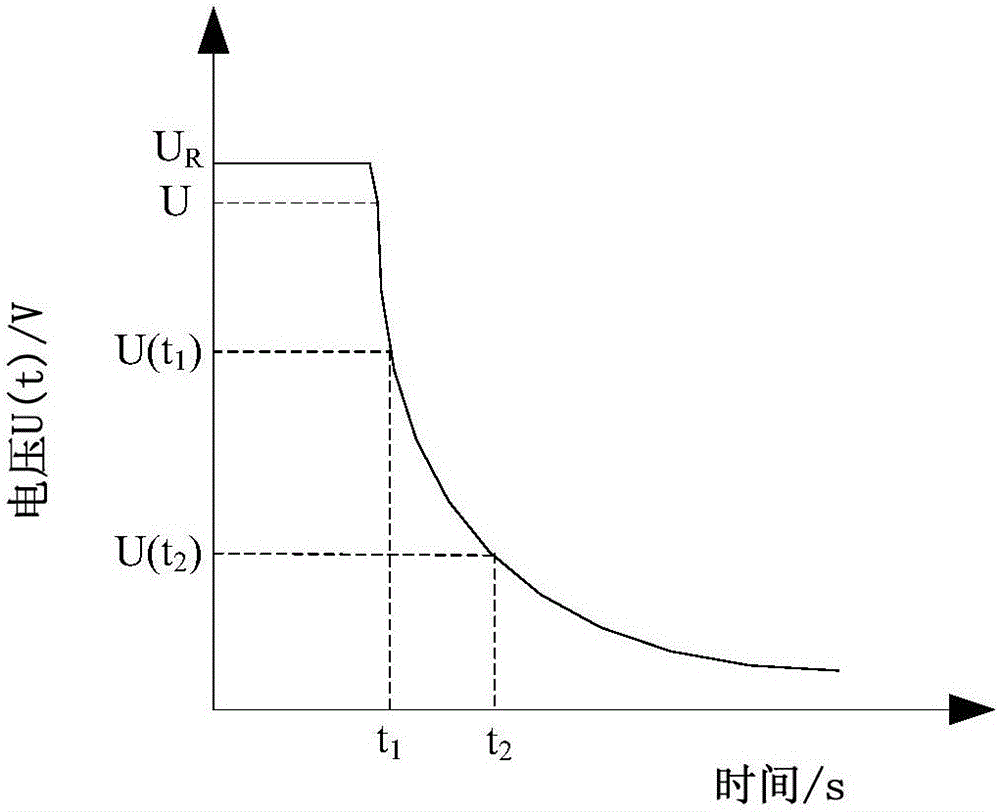

Method for measuring electrostatic capacity of supercapacitor and device thereof

ActiveCN105911373AAvoid measurement errorsLow requirements for measurement environmentElectrical measurementsVoltmeterVoltage rating

The invention discloses a method for measuring electrostatic capacity of a supercapacitor and a device thereof. The method comprises the steps that the supercapacitor is charged until voltage of the two ends of the supercapacitor reaches the rated voltage; charging is stopped, and discharging to a discharge loop connected with a sampling resistor R is performed so that the voltage of the two ends of the sampling resistor is acquired in real time; and the electrostatic capacity C of the supercapacitor is calculated according to the voltage of the two ends of the sampling resistor R. The device comprises a charging power supply, a voltmeter, the sampling resistor and a sampler. The voltmeter is connected in parallel with the two ends of the supercapacitor. A charging loop is formed by the charging power supply and the supercapacitor. The discharge loop is formed by the sampling resistor and the supercapacitor. The sampler is connected in parallel with the two ends of the sampling resistor. According to the method for measuring the electrostatic capacity of the supercapacitor and the device thereof, the method and the device have no relationship with stability of discharge current and have no requirement for the slope of a discharge curve so that measurement error of the electrostatic capacity can be reduced and measurement accuracy can be enhanced.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

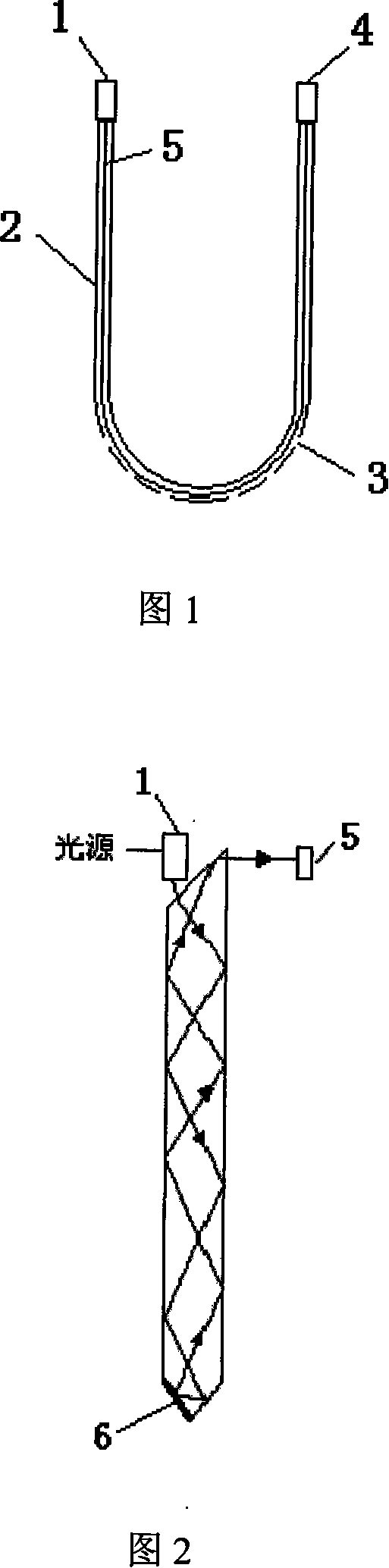

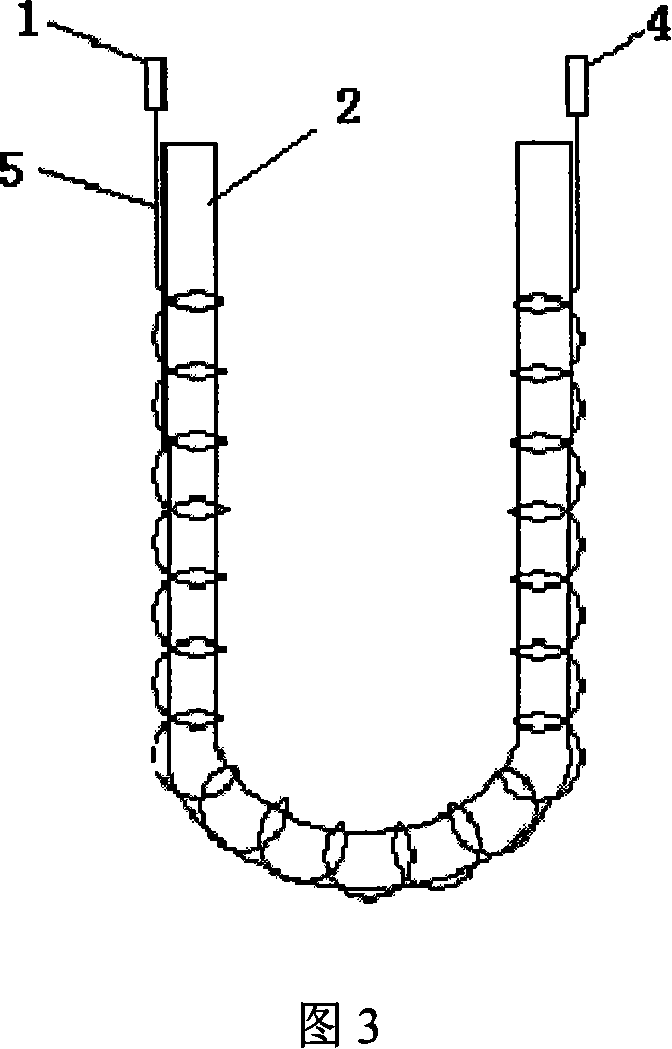

Photoelectric liquid level sensor and measuring method thereof

InactiveCN101140181AEasy to install and adjustSolution to short lifeMachines/enginesLevel indicatorsElectromagnetic interferenceEngineering

The invention discloses a photoelectric liquid level sensor and a measuring method; the photoelectric liquid level sensor comprises a laser and a photoelectric receiver, wherein the laser is connected with the photoelectric receiver through an optical fiber, the optical fiber is arranged in the a protection pipe, and the bottom of the protection pipe is provided with a plurality of holes. Or, the laser is communicated with the photoelectric receiver through a glass rod, the bottom of the glass rod is provided with a triple prism or a reflection device, the photoelectric liquid level sensor provided in the invention is arranged in the liquid, and the internal light transmission conditions are destroyed through changing the boundary condition of light transmission medium to result in that the output light intensity is in direct proportion to the liquid level height in order to measure the liquid level height. The sensor immerges into the liquid, adopts the optical device and has no electronic device, and thereby has the strong anti-electromagnetic interference ability and the good corrosion resistance and is particularly applied to the measurement of flammable and explosive liquid. The invention has the advantages of the small volume, the simple structure, the low cost, the convenient installation, no electric quantity in the liquid, and the safe and convenient measurement.

Owner:XI AN JIAOTONG UNIV +1

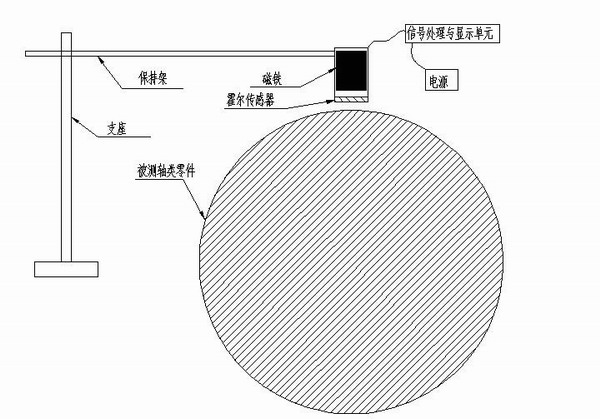

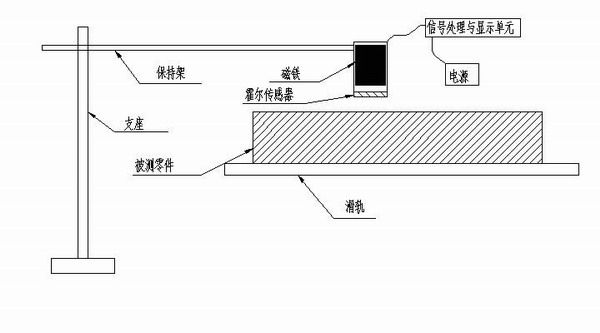

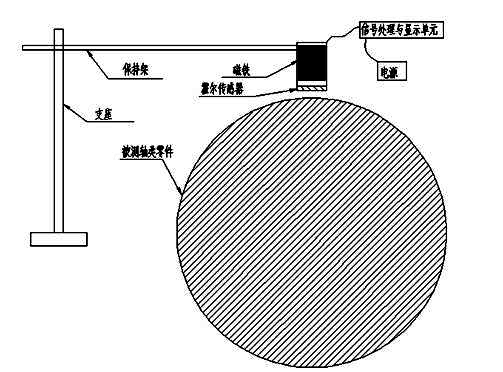

Measuring method for form and position tolerance

InactiveCN101922907AEasy to measureNo training requiredUsing electrical meansPosition toleranceEngineering

The invention relates to a measuring method for the form and the position tolerance of ferromagnetism parts by utilizing a Hall sensor, wherein a Hall linear output sensor is arranged between a part to be measured and a magnet, has a reasonable gap with the part to be measured and is perpendicular to the surface of the part to be measured; and all factors capable of causing the change of output voltage signals of the Hall sensor, except the appearance change of the surface of the part, need to be eliminated; when the Hall sensor and the surface of the part to be measured have relative motion or rotation, the gap between the magnet and the part to be measured changes because of the appearance change of the surface of the part to be measured; the gap change is reflected into the change of the output voltage of the Hall sensor; a signal processing and display unit collects output voltage signals of the Hall sensor; and the form and the position tolerance of the measured part can be obtained on the basis of the obtained voltage signal change, as well as calibration data and a tolerance formula. The measuring method has the advantages of non-contact measurement realization, high measurement accuracy, high speed, low cost, and automation and on-line detection.

Owner:陈凡

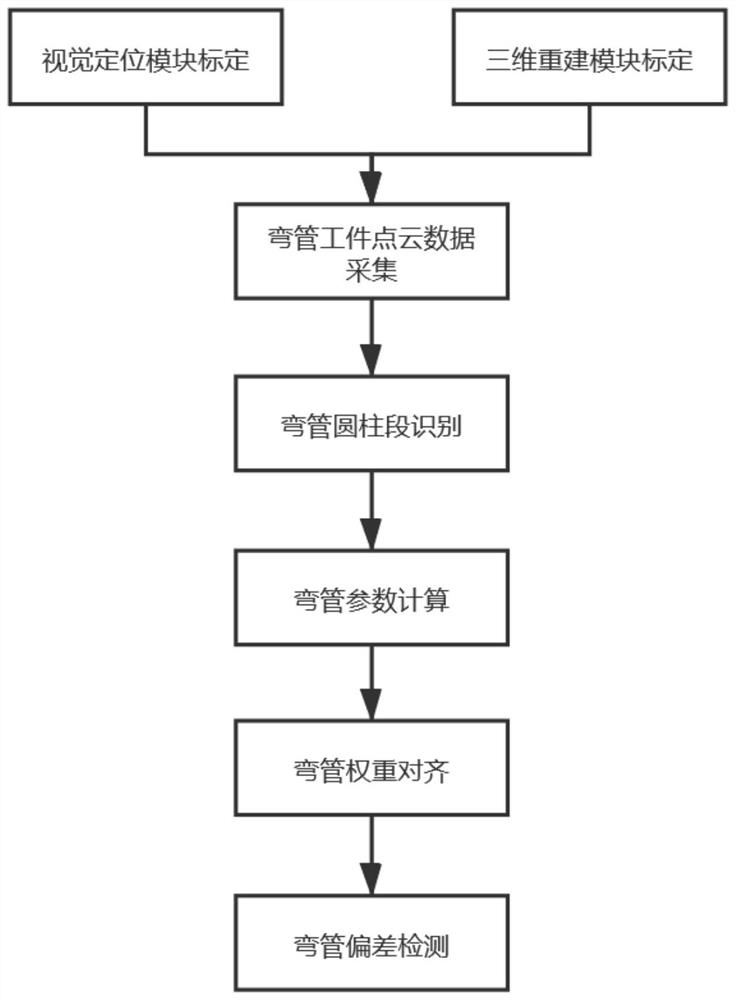

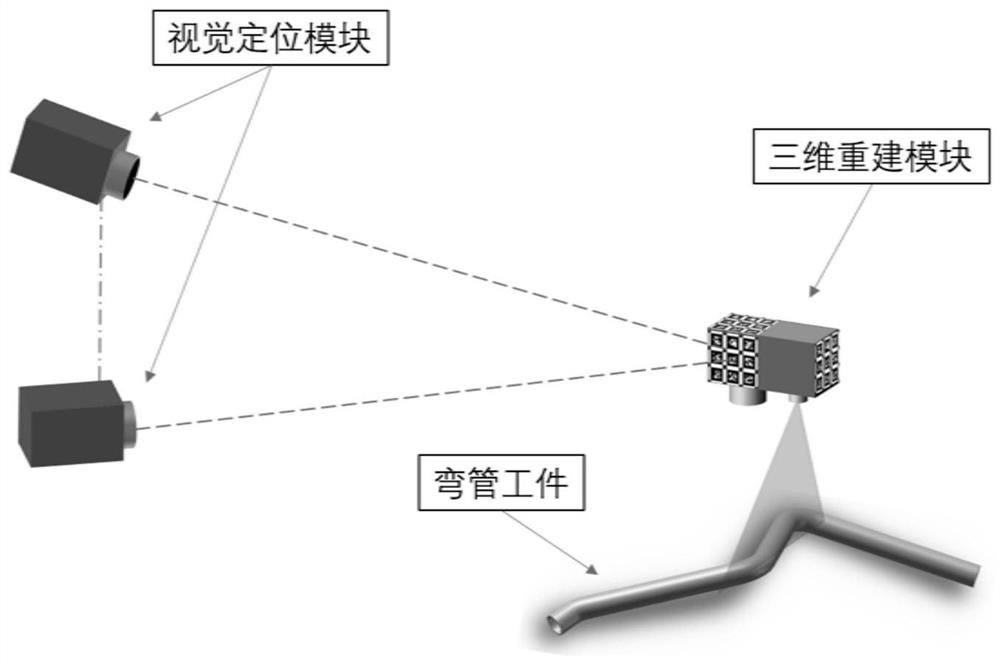

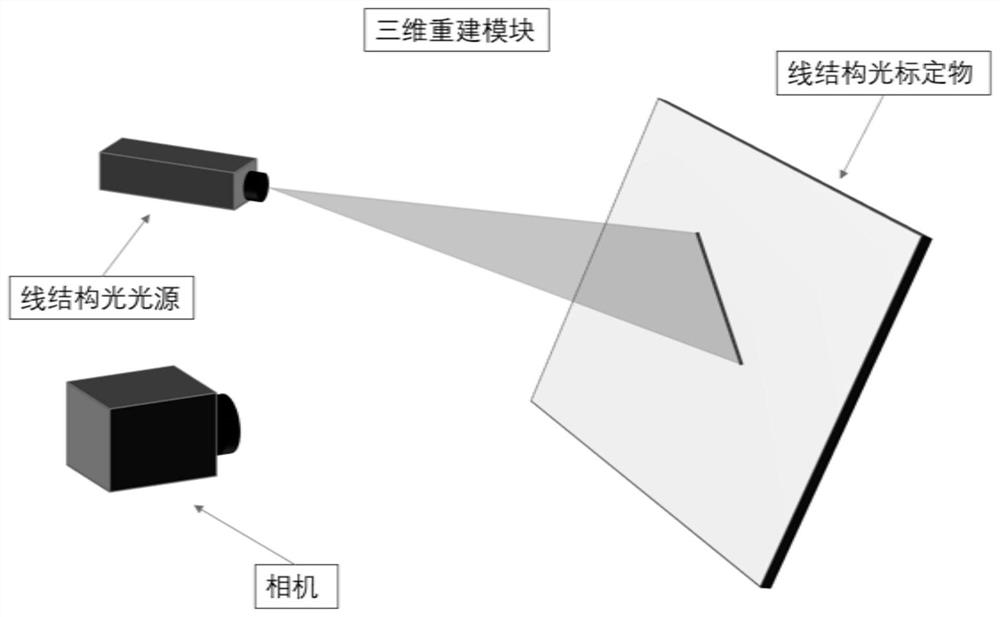

Visual inspection method and system for three-dimensional bent pipe

PendingCN111754462AMeet the point cloud acquisition requirementsImprove operational flexibilityImage analysis3D-image renderingPoint cloudAlgorithm

The invention discloses a visual detection method and system for a three-dimensional bent pipe, and the method comprises the steps: collecting an image of a to-be-detected bent pipe through a three-dimensional reconstruction module, obtaining single bent pipe point cloud data, and carrying out the visual positioning of the current spatial position and posture of the three-dimensional reconstruction module through a visual positioning module; fusing the single bent pipe point cloud data according to a visual positioning result to form complete bent pipe point cloud data; recognizing the cylindrical section and the arc section of the bent pipe according to the complete bent pipe point cloud data, and determining parameters of the cylindrical section and the arc section of the bent pipe. Therefore, the three-dimensional bent pipe workpiece can be rapidly and accurately detected, and the method and the system have the advantages of being convenient to operate, high in flexibility degree and accurate in measurement.

Owner:新拓三维技术(深圳)有限公司

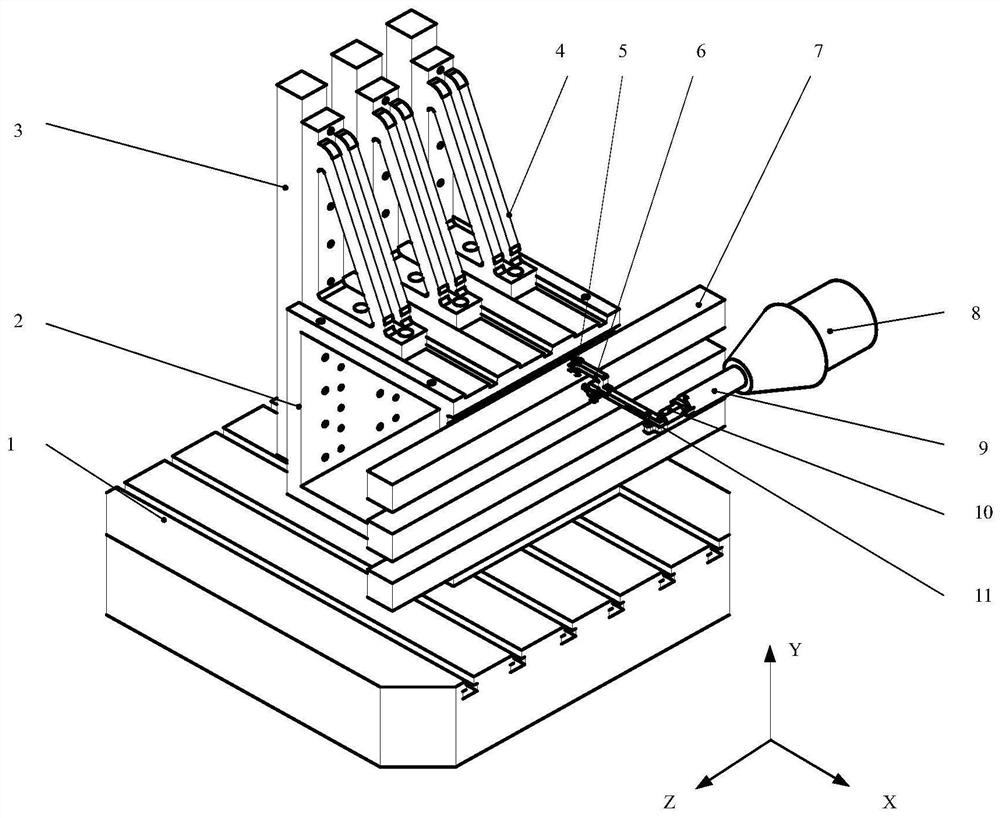

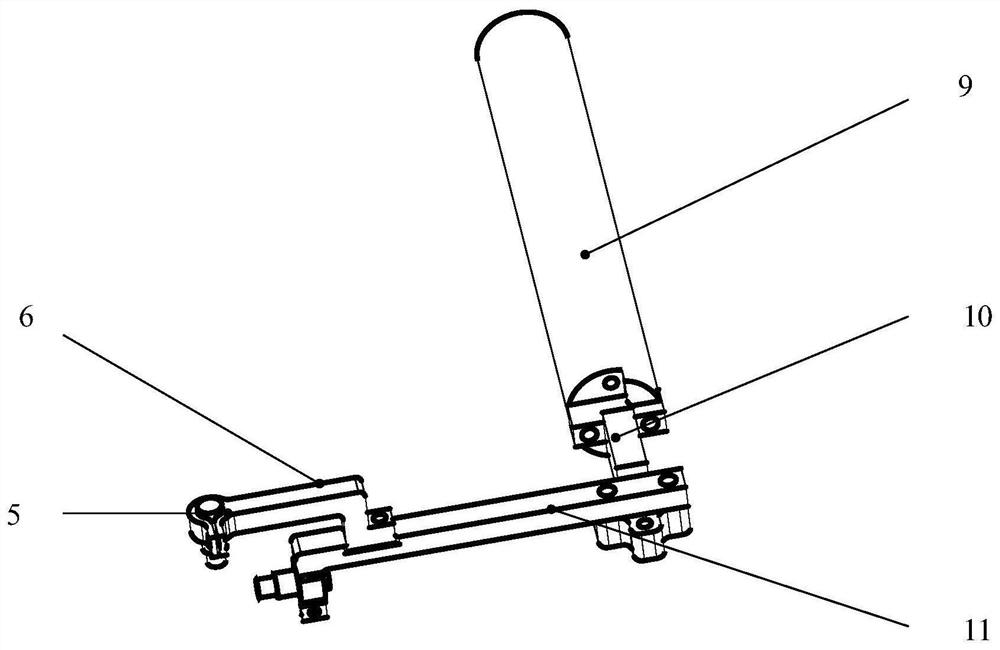

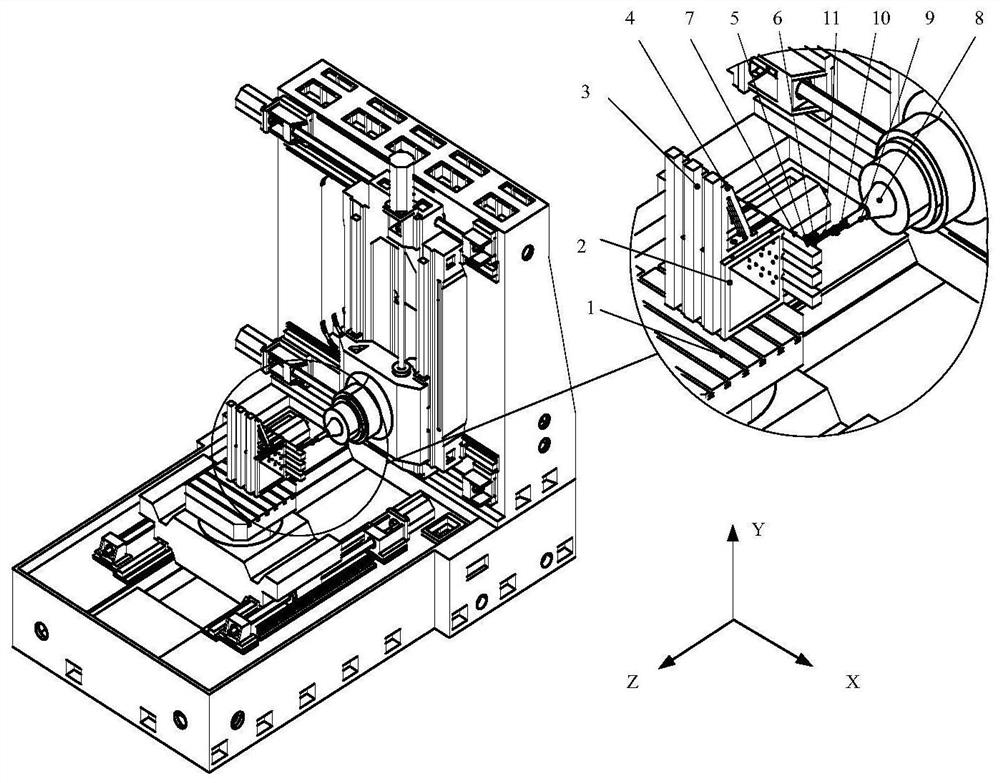

Device and method for detecting thermally induced straightness-perpendicularity errors of horizontal machining center

ActiveCN111872743AGuaranteed measurement accuracyReduce cost of measurementMeasurement/indication equipmentsUsing electrical meansEngineeringMachine tool

The invention provides a device and method for detecting thermally induced multi-line straightness-perpendicularity errors of a horizontal machining center. The device comprises an eddy current sensormeasurement module and a cast iron square box assembly reference module on the surface of a workbench. According to the technical scheme, the eddy current sensor measurement module is used for carrying out large-stroke measurement of multi-line straightness errors before and after machine tool heating on the reference module placed on the workbench of the precision horizontal machining center, and the multi-line thermally induced straightness-perpendicularity errors of a machine tool are further obtained; and by adopting the device, the thermally induced straightness-perpendicularity errors of three planes can be obtained at the same time, straightness-perpendicularity errors of different positions in the same plane can be obtained, so that the surface perpendicularity errors of any two measurement planes can be obtained, the measurement result is more accurate. The device and method are of great significance to the improvement of the machining precision and the precision retentivityof the precision horizontal machining center.

Owner:TIANJIN UNIV

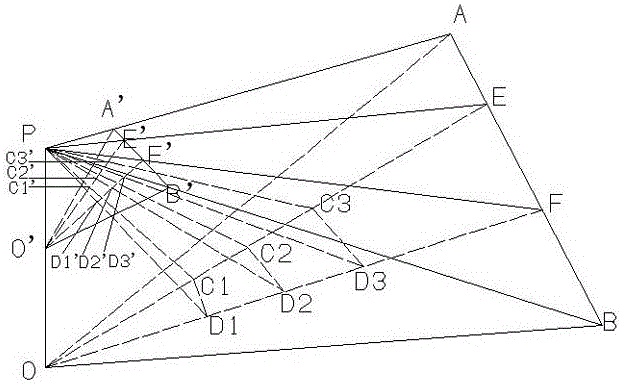

Method for measuring width of object based on single lens reflex

The invention discloses a method for measuring width of an object based on a single lens reflex. The method comprises steps of: erecting a tripod at a proper distance away from the object arranging the single lens reflex on the tripod, and arranging three reference points on connections lines between the center of the tripod and the object so as to shoot the target and the reference points to obtain pictures; measuring the actual distances of the reference points, the corresponding picture pixel distances and the corresponding pixel distance of the object; and inputting the measured data into a complied computing program to obtain the width of the object. The method is advantageous in that the measurement device such as the single lens reflex is common, light, highly applicable to environment, easy to operate, and high in measurement precision and can be used by specialists and laymen.

Owner:HOHAI UNIV

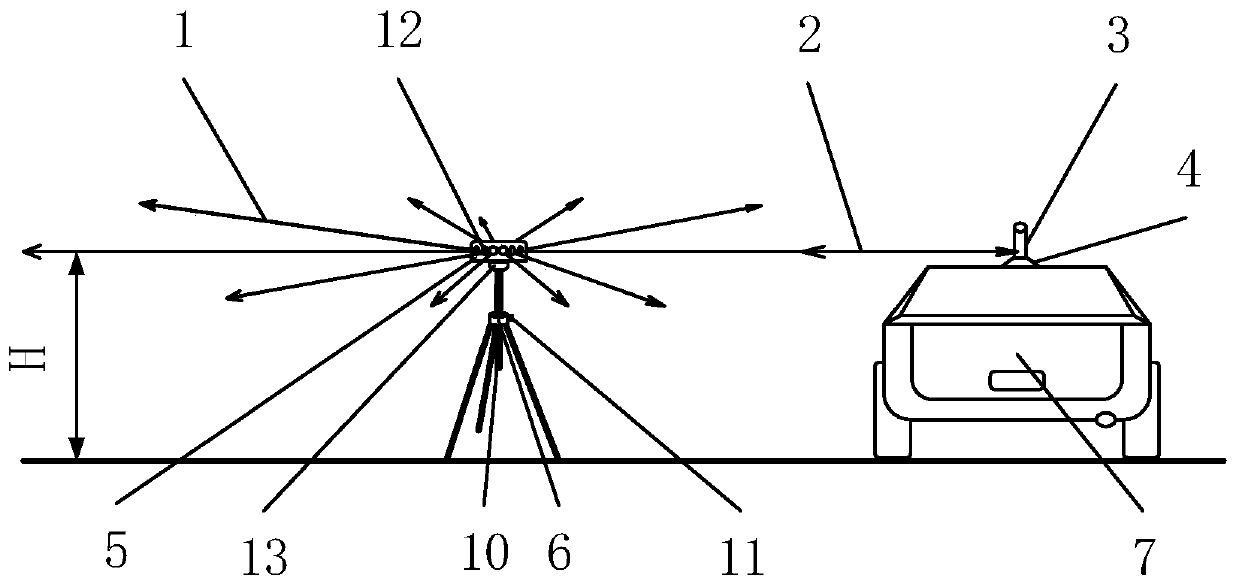

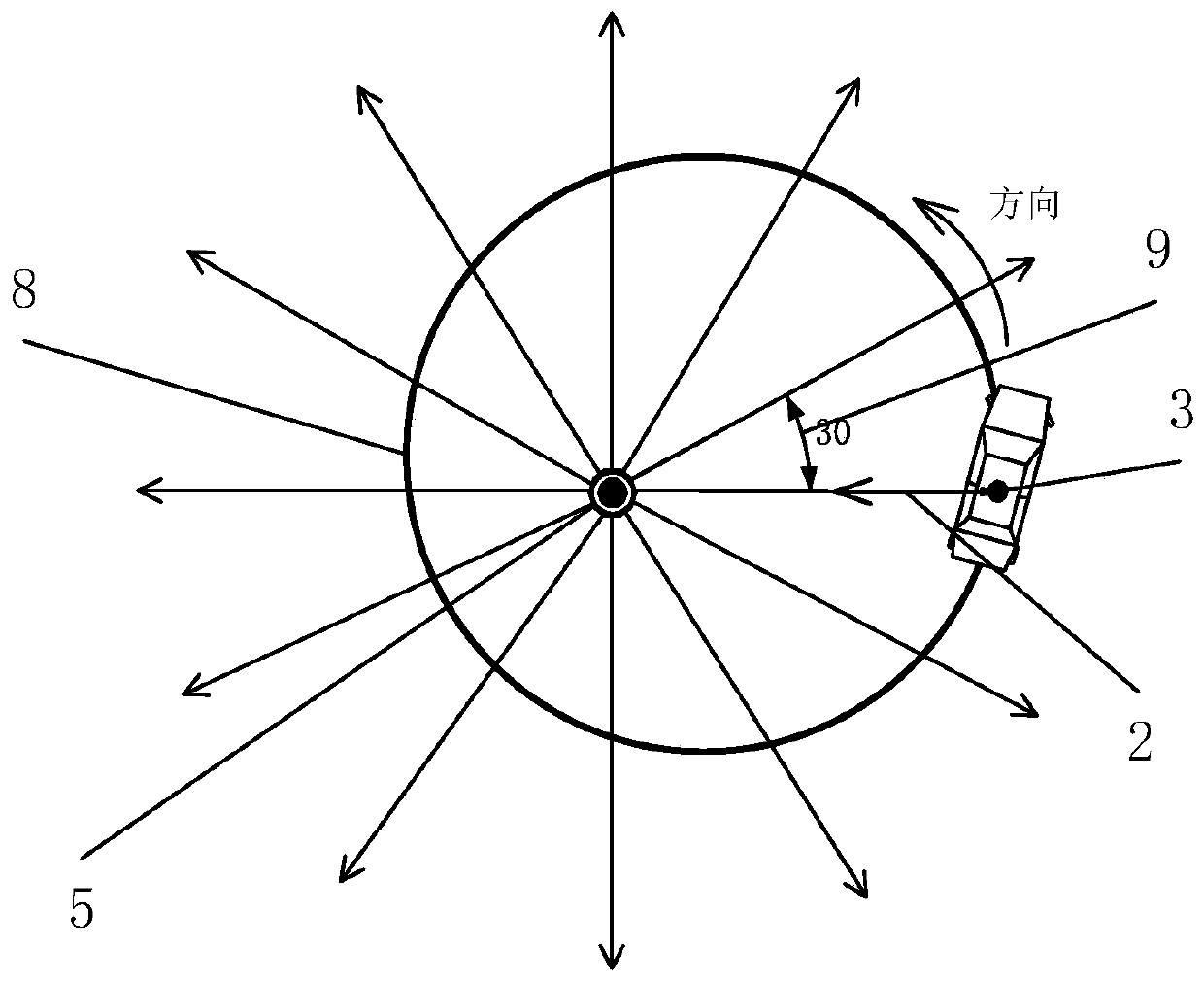

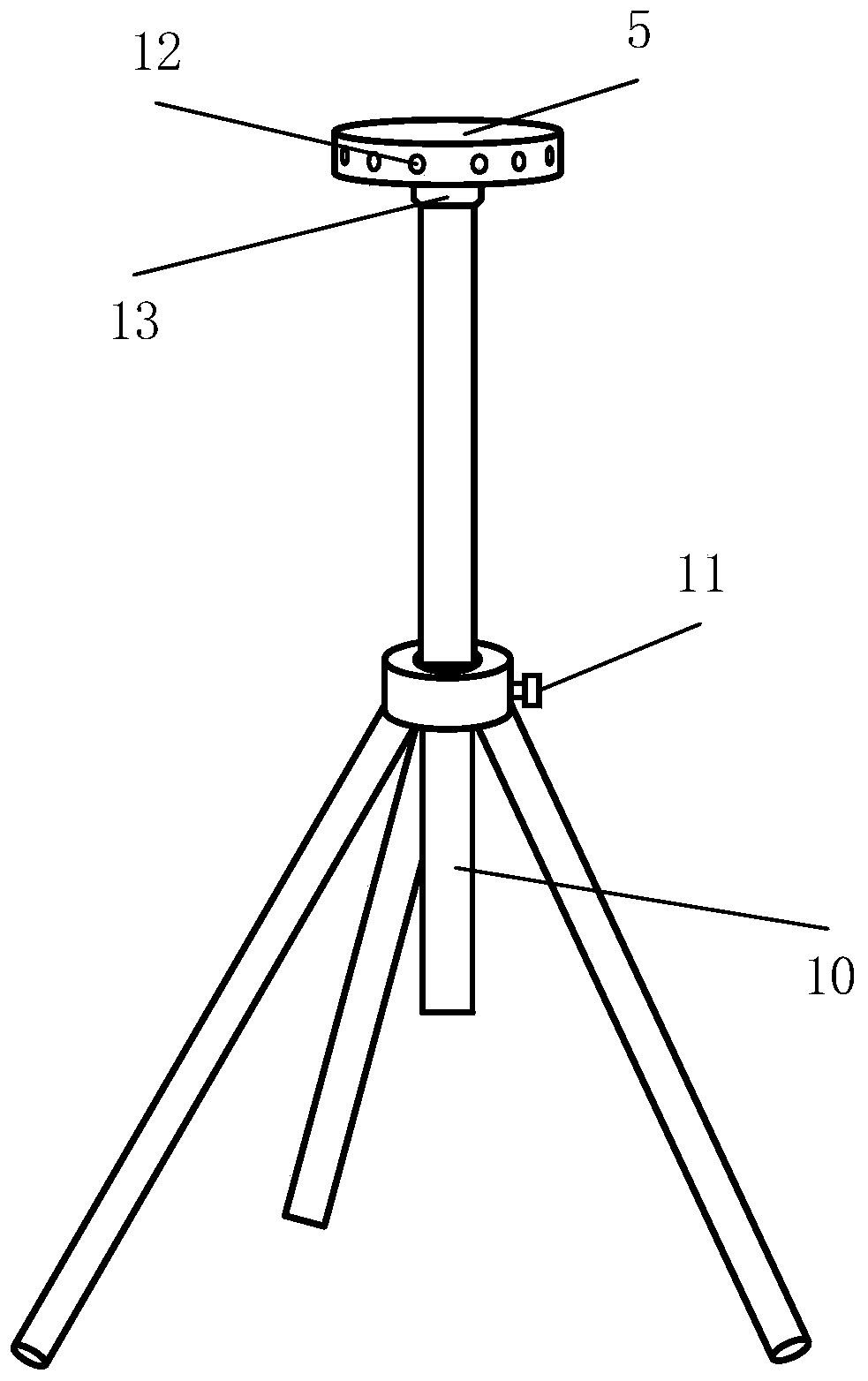

Automobile minimum turning diameter measuring system based on LD ranging and method

InactiveCN110057297AHigh degree of automationImprove work efficiencyUsing optical meansVehicle steering/rolling behaviourEngineeringVehicle detection

The invention relates to the vehicle detection technology, in particular to an automobile minimum turning diameter measuring system based on LD ranging and a method. The measuring method comprises anautomobile to be detected, an LD range finder, an LD reflecting device and a telescopic bracket. The bottom of the LD range finder is fixed on the telescopic bracket and the LD reflecting device as high as the LD range finder is located on a longitudinal axis of the automobile to be detected. The measuring system solves the problem that a measuring device needs to be installed again in case of left-turning and right-turning measurement of an automobile in the prior art, adopts the the most proven LD ranging technology and the wireless data transmission technology with the advanced measurementtechnology, achieves the integration of the measurement system and has simple structure, high measurement accuracy, low requirements for measuring environmental conditions and high repeatability, reduces the loss of manpower, material and financial resources during measurement; and improves the problems in traditional measurement methods such as complicated structure of devices, higher requirements for measurement environment conditions and lower precision, complicated measurement process and lower repeatability.

Owner:WUHAN UNIV OF SCI & TECH

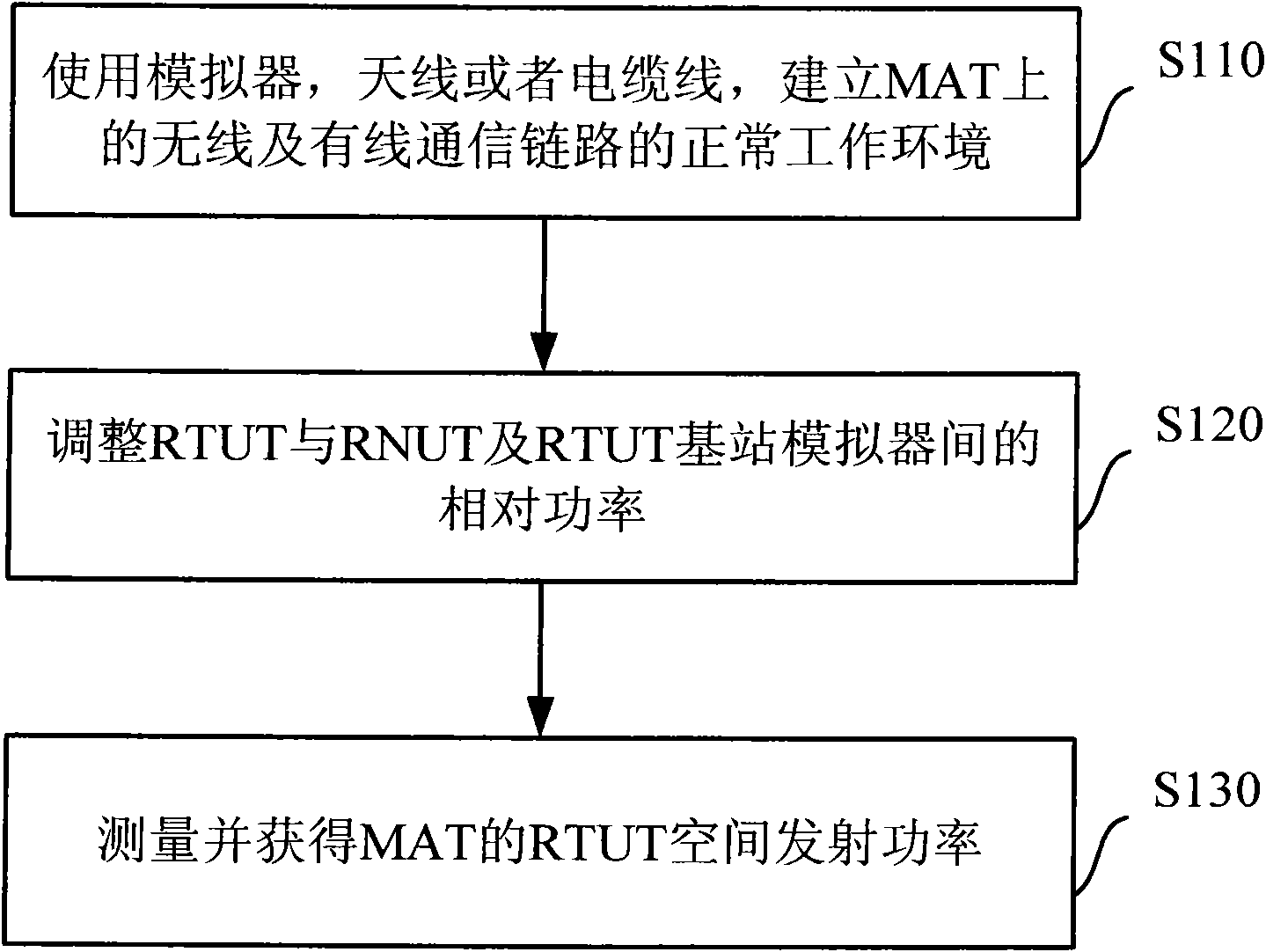

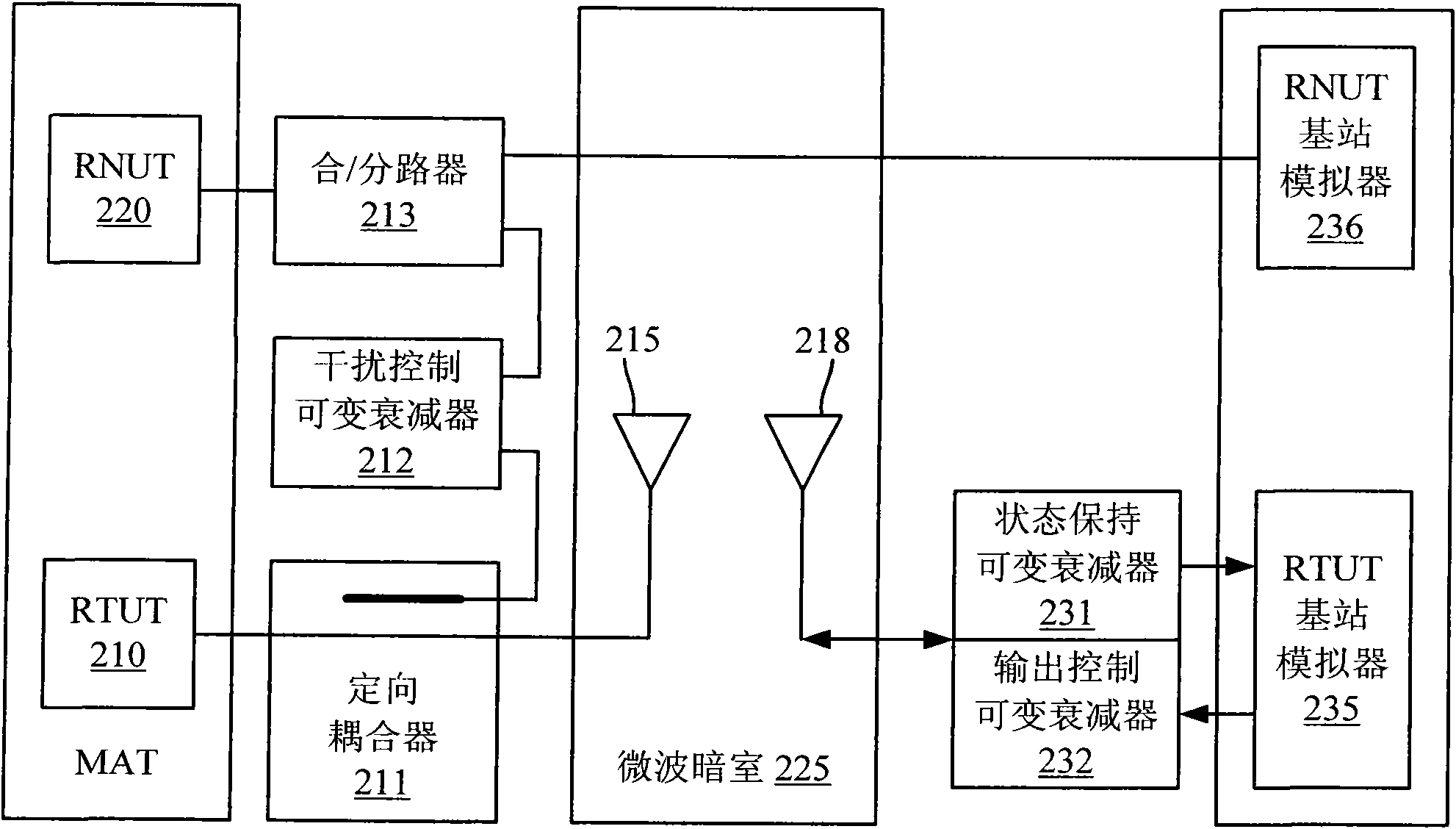

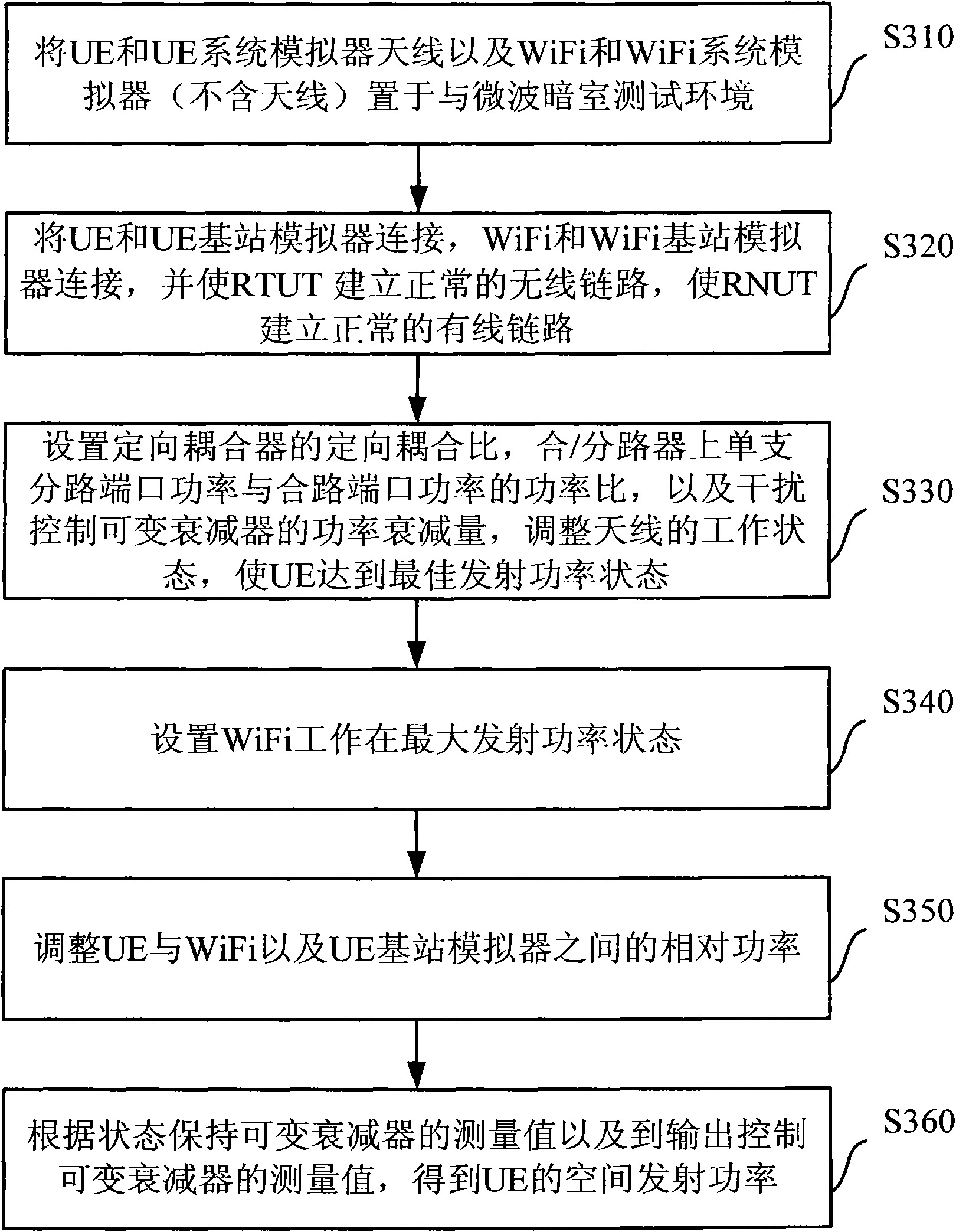

Measuring method for space transmission power of receiving terminal under test in multi-access terminal

ActiveCN101969349ALow requirements for measurement environmentEasy to testReceivers monitoringWireless communicationWired communicationWorking environment

The invention discloses a measuring method for the space transmission power of a receiving terminal under test in a multi-access terminal so as to improve the accuracy on measuring the space transmission power. The measuring method comprises the steps of: establishing a normal work environment for a wireless communication link and a wired communication link on the multi-access terminal; adjusting a relative power among the receiving terminal under test (RTUT), a radio not under test (RNUT) and a RTUT simulator; and measuring and obtaining the RTUT space transmission power of the multi-access terminal. Compared with prior art, the invention adopts an equivalent noise method to measure the transmission power of the receiving terminal under test, including an antenna, and has the advantages of low requirement on measurement environment and simple and easy test.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Method for generating and measuring left and right eye crosstalk value signal

ActiveCN103051920AIntuitive and fast readingLower requirementTelevision systemsSteroscopic systemsLuminance meterComplex calculation

The invention relates to a method for generating and measuring a left and right eye crosstalk value signal, which comprises the following steps of: firstly, selecting at least two brightness values and arranging at least two brightness values to form a crosstalk source signal with background brightness and light and dark strips; and then generating an interfered signal according to the crosstalk source signal, using the brightness value of the background brightness of the crosstalk source signal as background brightness of the interfered signal, selecting at least one crosstalk value and calculating a brightness value of the light and dark strips of the interfered signal according to the crosstalk value. When the signal generated by the technical scheme disclosed by the invention is adopted to measure a left and right eye crosstalk value, auxiliary tools such as a brightness meter and the like are not required, direct-read measurement is realized, the requirement on the measurement environment also can be reduced, and the crosstalk value measurement is not required to be completed in the darkroom environment. According to the invention, the technical basis is provided for the crosstalk value measurement, the testing operation process is simplified, and the crosstalk value can be visually, rapidly and conveniently read without massive complex calculation.

Owner:MUDAN SHIYUAN ELECTRONICS BEIJING

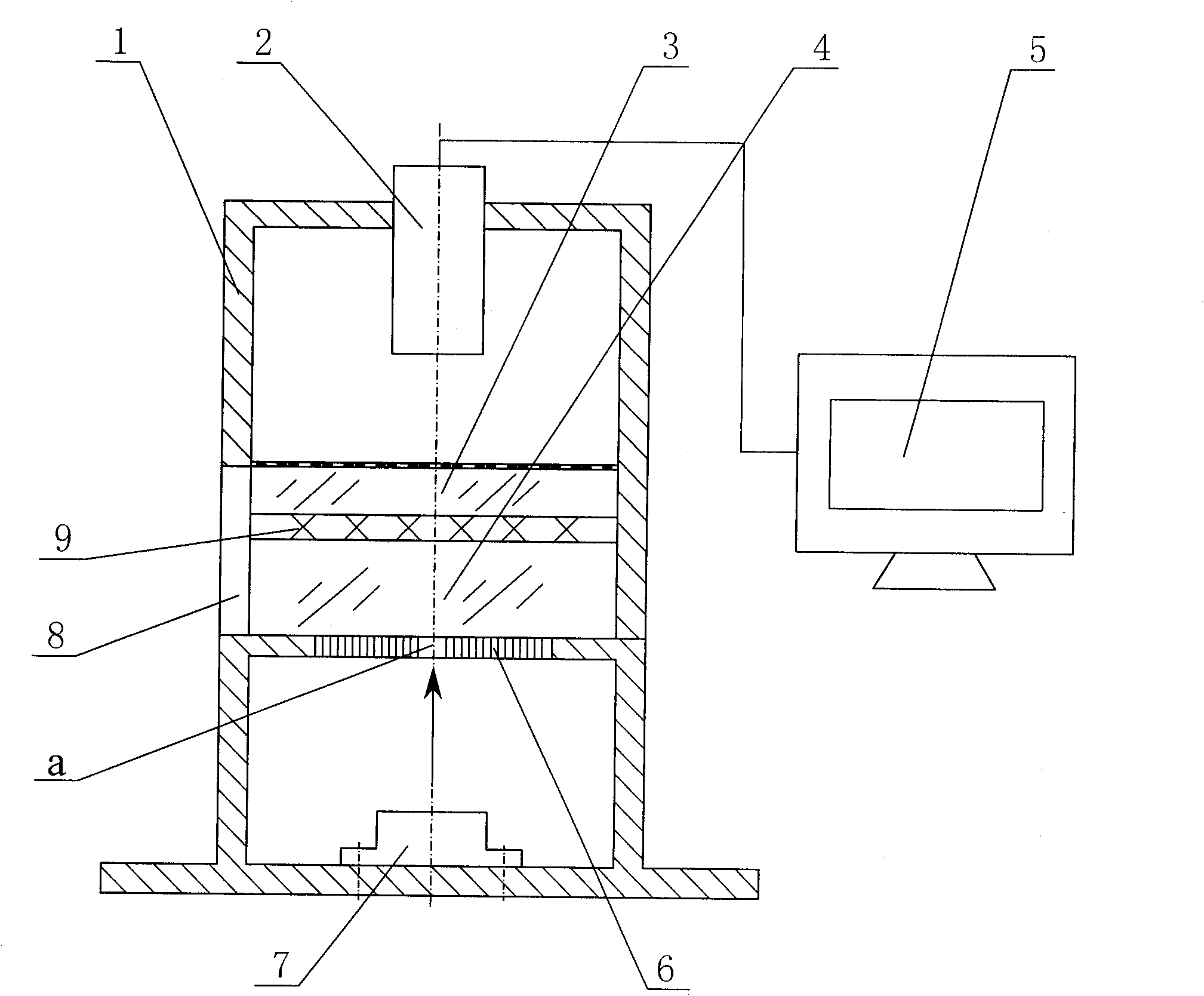

Experimental apparatus for measuring refractive indexes of liquid and measuring method thereof

InactiveCN101799413AReduce dosageReduce construction costsPhase-affecting property measurementsBouffantMeasurement device

The invention relates to an experimental apparatus for measuring refractive indexes of liquid. A luminescent device is arranged at the lower end of a cassette; a diaphragm is arranged on the cassette above the luminescent device; flat transmission glass is arranged on the upper surface of the diaphragm; flat image display glass is arranged on the upper surface of the flat transmission glass; a window is machined on the left side of the cassette, and the window is provided with a shading cover; bouffant shading paper is arranged at the upper end of the cassette; two stand columns are arranged on a base; millesimal position finder with scales is arranged at the upper ends of the two stand columns; a hand wheel is arranged at the end of the millesimal position finder; the hand wheel is connected with a lens cone of which the second lower part passes through the bouffant shading paper to penetrate into the cassette through a rotary translation switching mechanism; and a sealplate is arranged between the lens cone and the bouffant shading paper. A method for measuring the refractive indexes of liquid through the measuring device comprises the steps that: liquid to be measured forms a liquid film between the flat transmission glass and the flat image display glass; visible light passes through a clear aperture and the flat transmission glass, and the liquid film of the liquid to be measured to form a circular dart spot which takes an incidence point as the centre of a circle on a frosted surface of the flat image display glass; and the refractive indexes of the liquid to be measured are calculated.

Owner:SHAANXI NORMAL UNIV

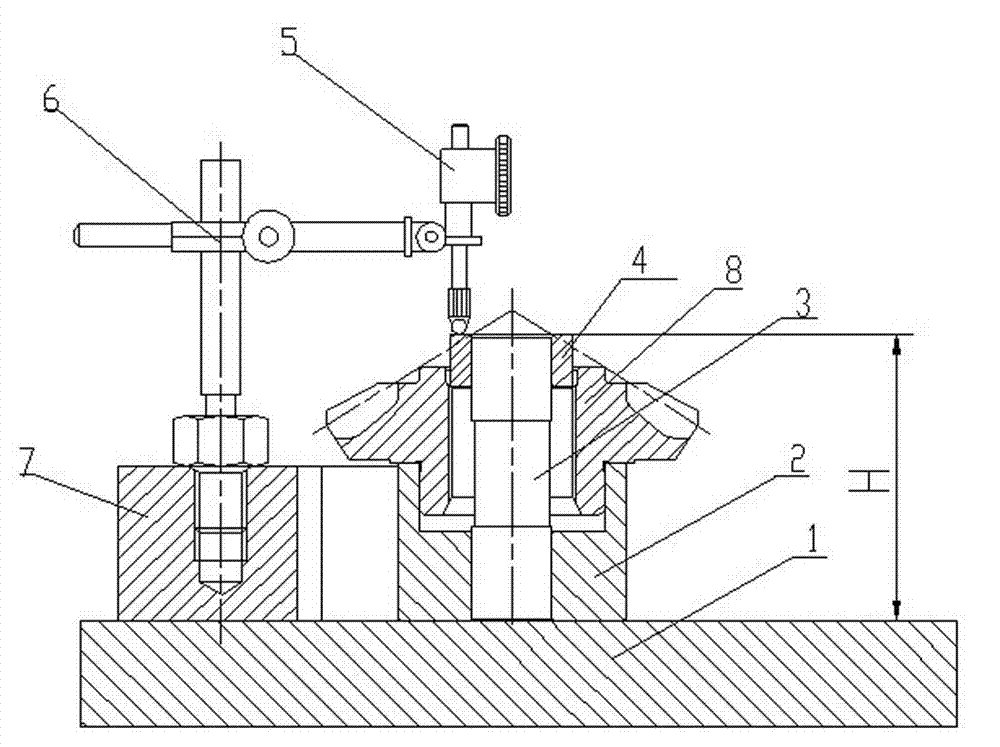

Gauge for indirectly measuring inner hole spigot angle of differential bevel gear

ActiveCN102954750ASimple structureReasonable structureAngles/taper measurementsHeight differenceEngineering

The invention discloses a gauge for indirectly measuring an inner hole spigot angle of a differential bevel gear. The gauge comprises a flat plate, a base, a core shaft, a locating sleeve, a dial indicator, a gauge stand and a V-shaped block, wherein the base and the V-shaped block are respectively arranged on the flat plate, and the horizontal V-shaped block is provided with a locating and measuring mechanism consisting of the gauge stand and the dial indicator; the base is provided with countersinks and a coaxial through hole, a workpiece is arranged in a countersink at the upper part of the base, and the core shaft is arranged in the through hole in a locating manner; an inner hole of the locating sleeve is in clearance fit with the core shaft, the locating sleeve respectively forms a small locating sleeve and a large locating sleeve according to two diameter values of a forming angle of a workpiece inner hole spigot, the small locating sleeve and the large locating sleeve are sequentially matched with the core shaft and are axially retained in the workpiece inner hole spigot, and the dial indicator of the locating and measuring mechanism respectively measures the heights from the upper end surfaces of the small locating sleeve and the large locating sleeve to the flat plate so that an angle error of the inner hole spigot is judged according to the height difference. The gauge disclosed by the invention has a pure mechanical structure and a low requirement on a measurement environment, is especially suitable for being configured in the production field, and is beneficial to immediate detection so as to reduce the economic loss caused by batch scrap.

Owner:JIANGSU PACIFIC PRECISION FORGING +1

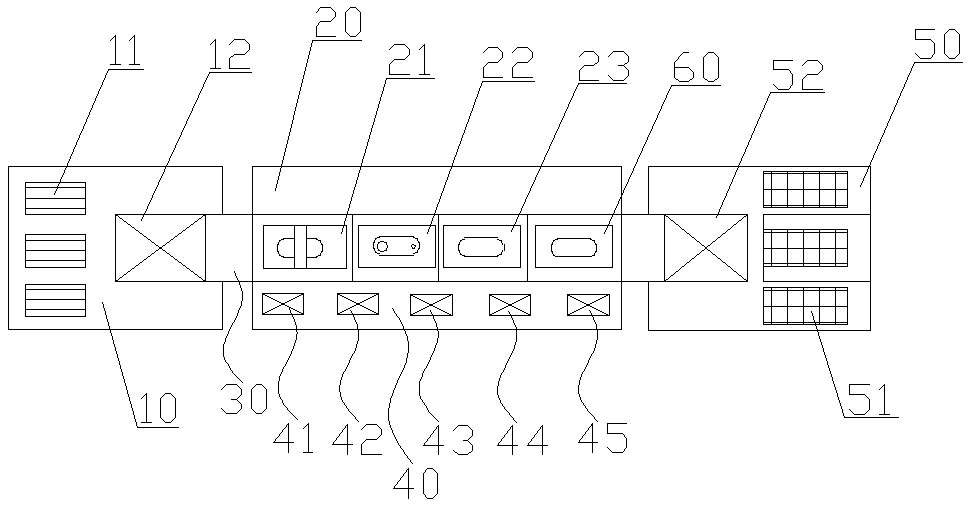

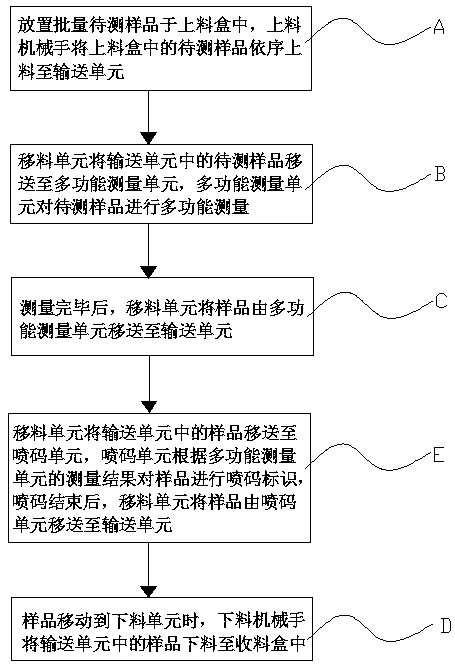

Automatic measuring apparatus and measuring method of multifunctional mobile phone backboard

PendingCN108267177AConvenience for subsequent useSmall footprintMeasurement devicesSurface stressDimension measurement

The invention belongs to the field of the quality detection of a mobile phone panel and backboard, and particularly relates to an automatic measuring apparatus and measuring method of a multifunctional mobile phone backboard which can automatically complete the dimension measurement, flatness measurement, transmittance measurement and surface stress measurement of the mobile phone backboard. The automatic measuring apparatus comprises a loading unit, a multifunctional measuring unit, a conveying unit, a shifting unit, an unloading unit and a control unit, wherein when in use, a batch of to-be-measured samples is arranged in the loading unit, a loading manipulator successively loads the to-be-measured samples to the conveying unit, the conveying unit drives the to-be-measured samples to move to the multifunctional measuring unit to be multifunctionally measured, the dimension measurement, the flatness measurement, the transmittance measurement and the surface stress measurement can be completed in one step, the occupied space is small, the requirement on the measuring environment is low, time and labor are saved, the working efficiency is high, the mass detection requirement can bemet, no manual operation is needed in the measuring process, the automation degree is high, different functional measuring units can be added or reduced according to the requirement, and the application prospect is wide.

Owner:SHENZHEN JINGCHUANG TECH CO LTD

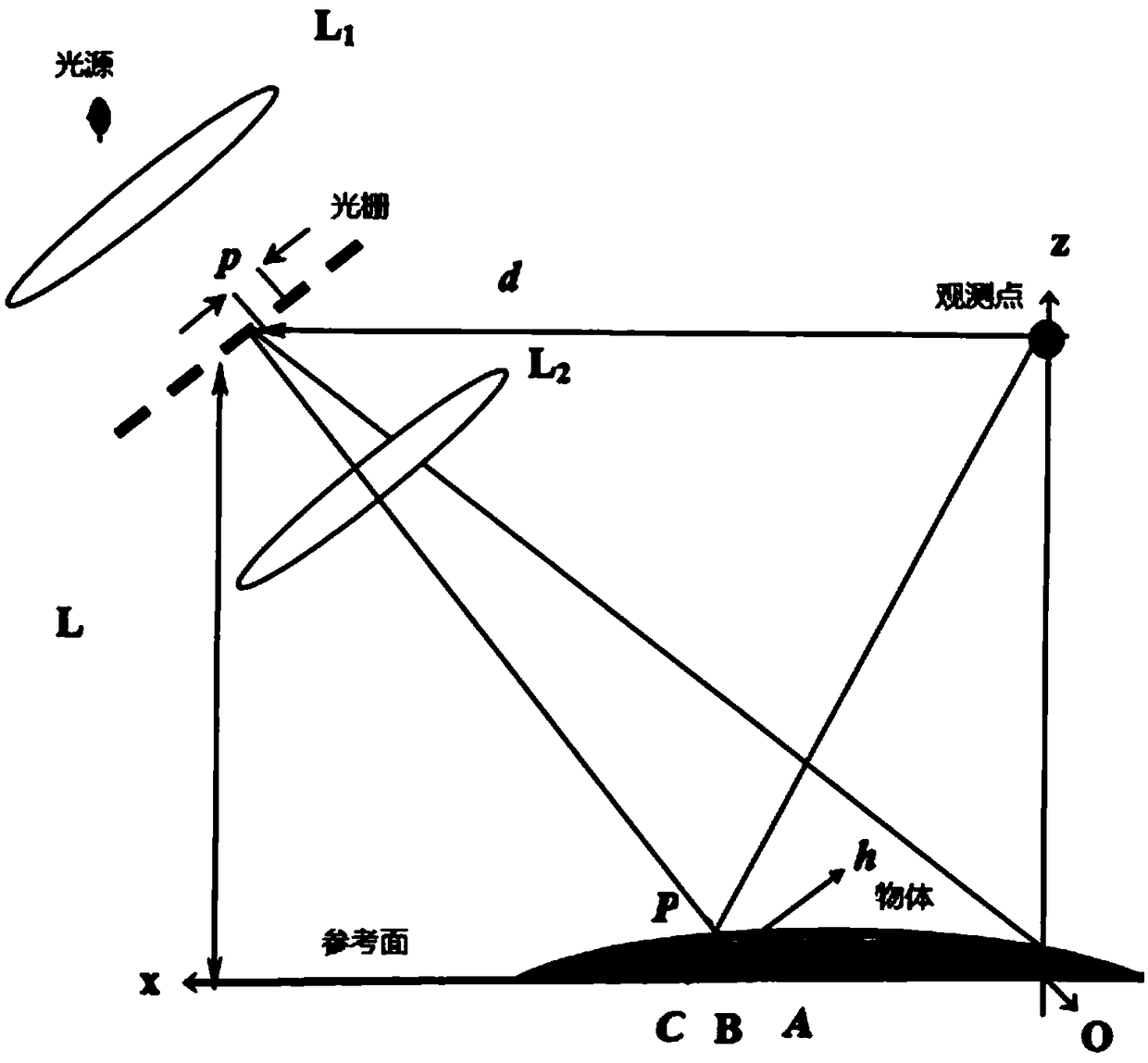

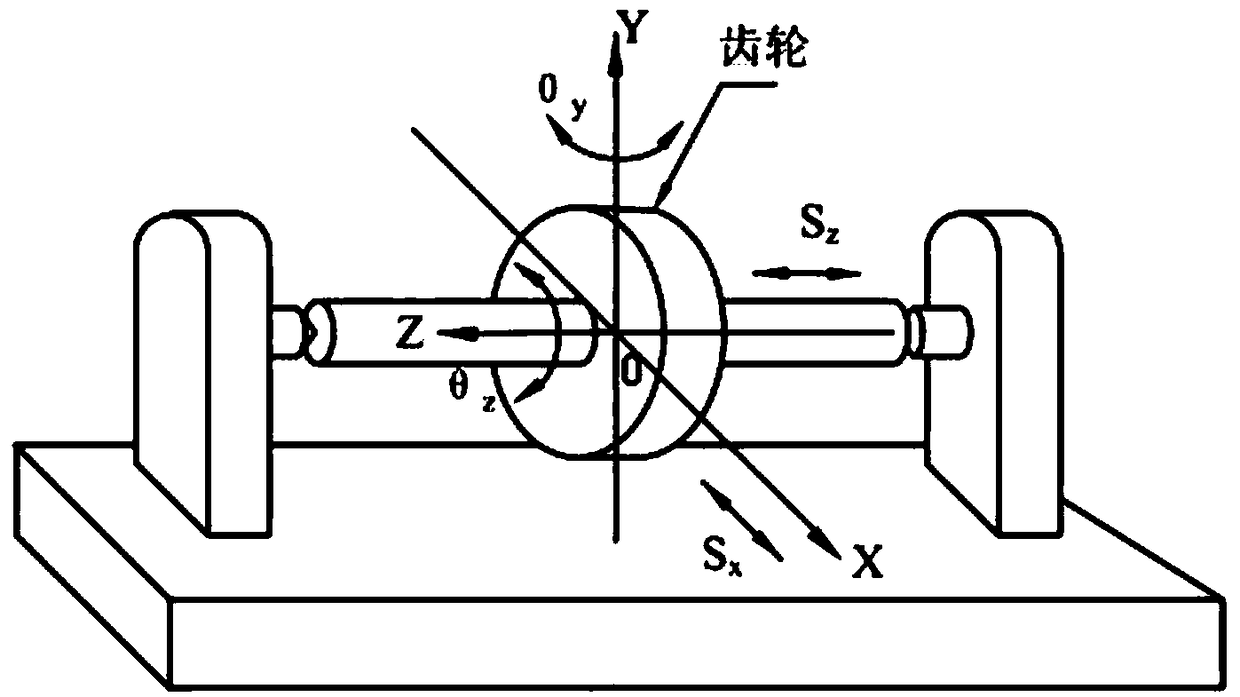

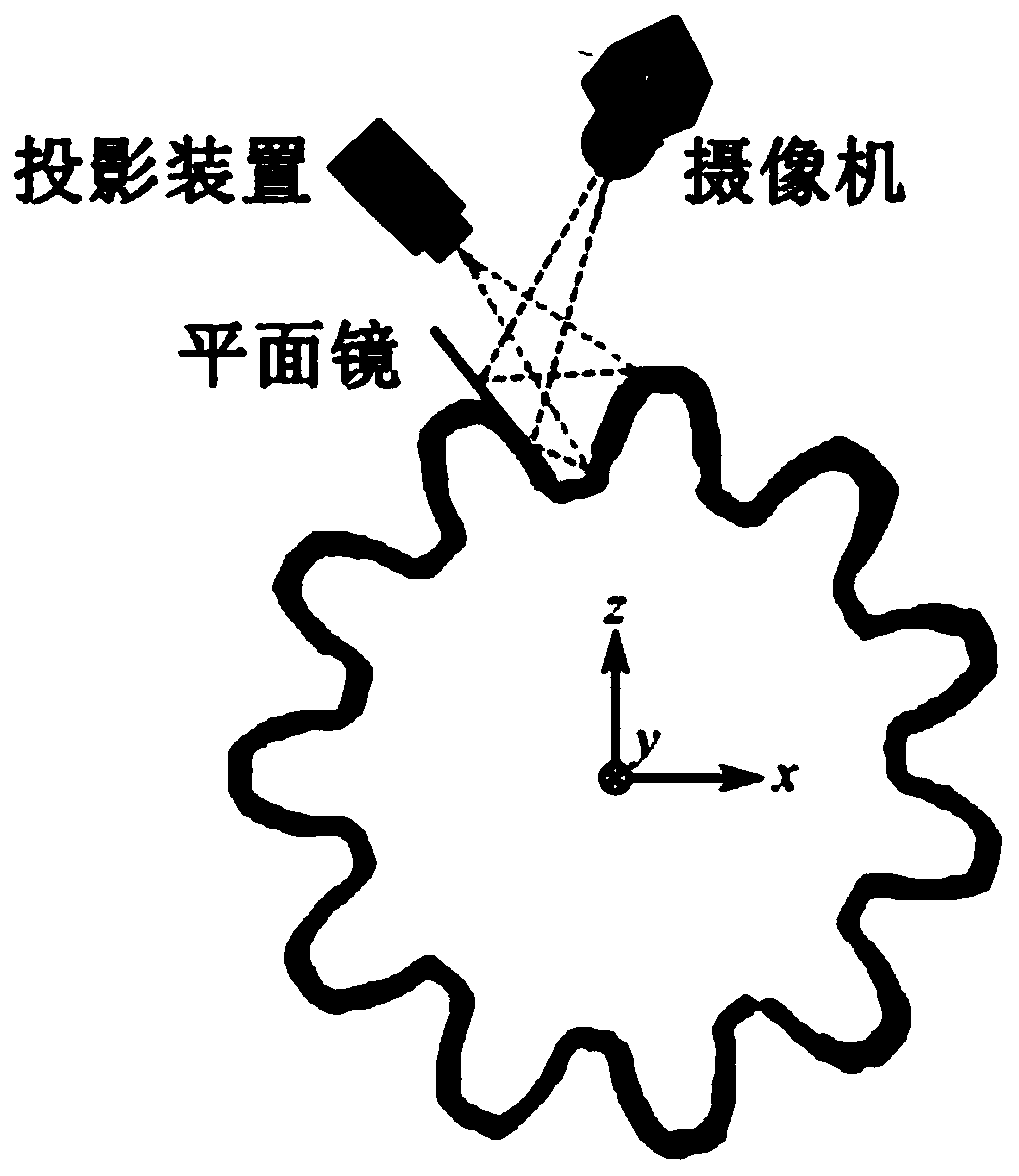

Three-dimensional shape characterization method for gear tooth surface

The invention provides a three-dimensional shape characterization method for a gear tooth surface in real grating projection. The method uses a plane moving grating to introduce a uniform phase shiftfor the measurement field of view, and constructs a random phase shift technique to eliminate the offset error in the phase demodulation process. The method uses the phase as the measurement feature,and uses its invariance characteristics to construct a phase-height difference look-up table to quickly recover the three-dimensional measurement surface, and finally provides a way to construct a fast, high-precision gear three-dimensional contour measurement technology. The method of the invention provides an effective way for non-contact measurement of spur gears and helical gears.

Owner:XIAN TECHNOLOGICAL UNIV

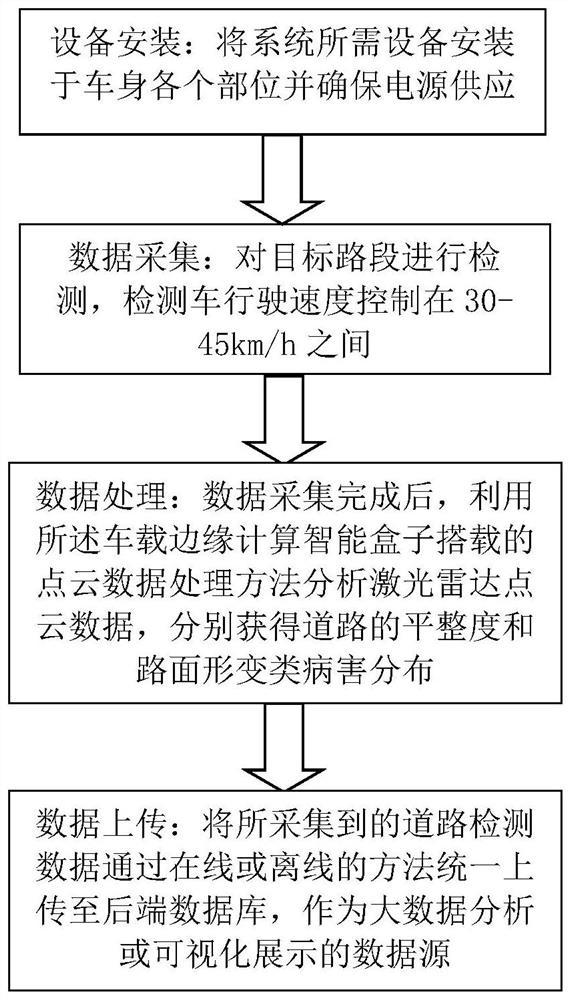

Road inspection system and method based on vehicle-mounted laser radar

ActiveCN112965077ALow requirements for measurement environmentWide detection rangeNavigation by speed/acceleration measurementsSatellite radio beaconingIn vehicleRadar

The invention provides a road inspection system and method based on a vehicle-mounted laser radar. The system comprises a vehicle-mounted inertial navigation device, a single-line laser radar, a high-precision GPS positioning device and a vehicle-mounted edge computing intelligent box. The road inspection method based on the vehicle-mounted laser radar is provided based on the system and comprises the following steps of device installation, data acquisition, data processing and data uploading. The road detection system and the road detection method provided by the invention have the advantages of low requirement on a measurement environment, wide detection range, realization of multi-lane and full-road-width road detection through single measurement, and high precision of a detection result. Moreover, the measurement mode is vehicle-mounted measurement, the measurement speed is high, the efficiency is high, the method is suitable for large-range road detection, the detection period can be greatly shortened, the detection frequency is effectively reduced under the same detection coverage range, and more labor cost is saved.

Owner:SHANGHAI TONGLU CLOUD TRANSPORTATION TECH CO LTD

Calibration device for detecting vacuum gauges with relative errors of indicating values no less than 30%

InactiveCN104198115ALow costLow requirements for measurement environmentFluid pressure measurementEngineeringControl valves

The invention discloses a calibration device for detecting vacuum gauges with relative errors of indicating values no less than 30%. The calibration device comprises a vacuum pump, a standard vacuum gauge, a calibrated vacuum gauge, a calibration room and connection pipelines. The vacuum pump is connected with the calibration room through a pipeline provided with a control valve, the connection pipeline is communicated with the calibration room, and the standard vacuum gauge and the calibrated vacuum gauge are mounted at ports of the connection pipelines. The calibration device is simple in structure, convenient to operate and low in cost; due to the fact that the plurality of connection pipelines are welded to two ends of the calibration room, a plurality of calibrated vacuum gauges can be detected at the same time, and accordingly detection efficiency is improved.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

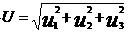

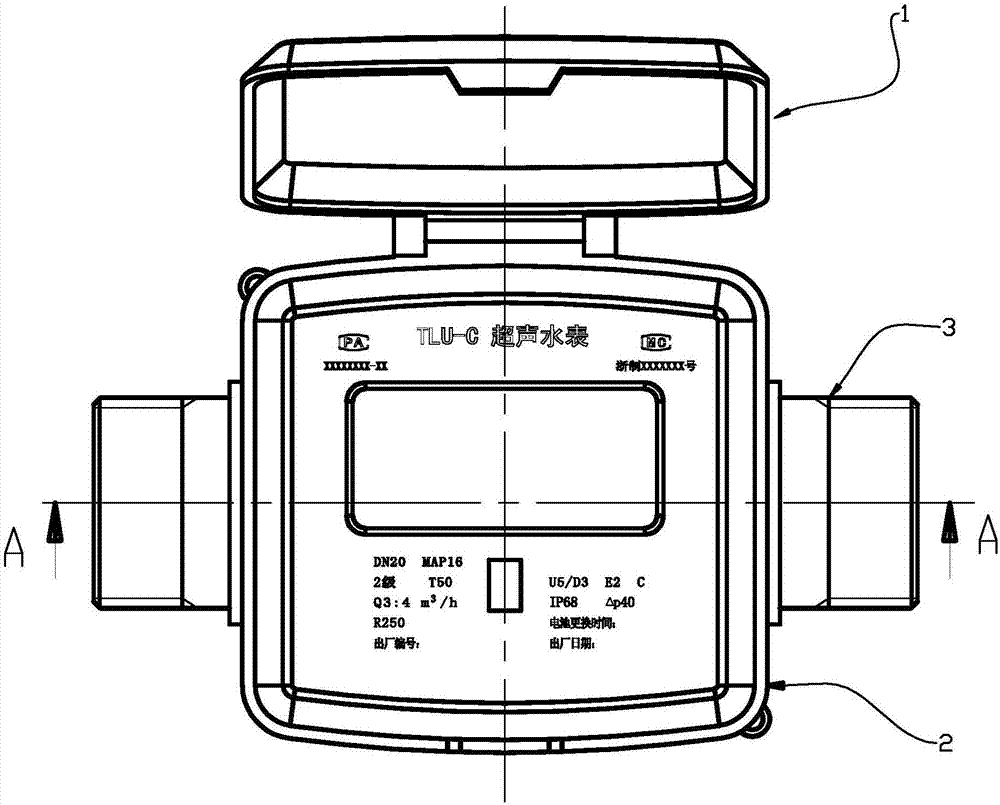

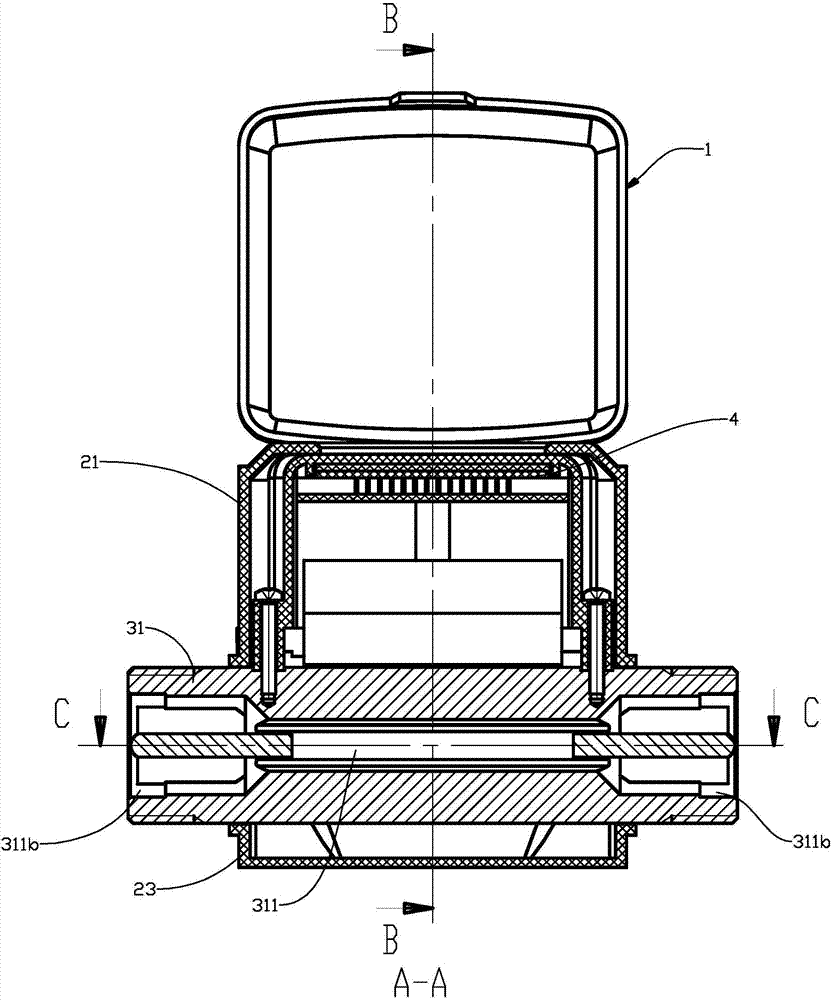

Small-bore ultrasonic water meter

PendingCN107576360ARealize an integrated structureHigh measurement accuracyVolume/mass flow measurementVolume meteringMeasurement precisionUltrasound probe

The invention discloses a small-bore ultrasonic water meter. The water meter comprises a meter lid and a meter shell, the meter shell comprises an upper outer shell, a lower outer shell and an ultrasonic flow reflection device installed between the upper outer shell and the lower outer shell, the ultrasonic flow reflection device comprises a reflection shell, a fluid channel is formed in the reflection shell, the ultrasonic flow reflection device comprises an ultrasonic probe and a reflection body, the ultrasonic probe is embedded into the side wall, close to the upper outer shell, of the fluid channel and sealed through glue filling, and the reflection body is axially installed at an end opening of the fluid channel along the fluid channel and fixed into the fluid channel through a supporting frame. The small-bore ultrasonic water meter is good in seal performance and high in measurement precision because the ultrasonic probe does not contact with fluid media.

Owner:ZHEJIANG TIANXIN INSTR TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com