Gauge for indirectly measuring inner hole spigot angle of differential bevel gear

A technology of inner hole spigot and bevel gear, which is applied in the field of indirect measurement of the bevel gear inner hole spigot angle inspection tool, can solve the problems of batch scrapping, low detection efficiency, and high requirements for inspection conditions, and achieves easy production, convenient operation, The effect of accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

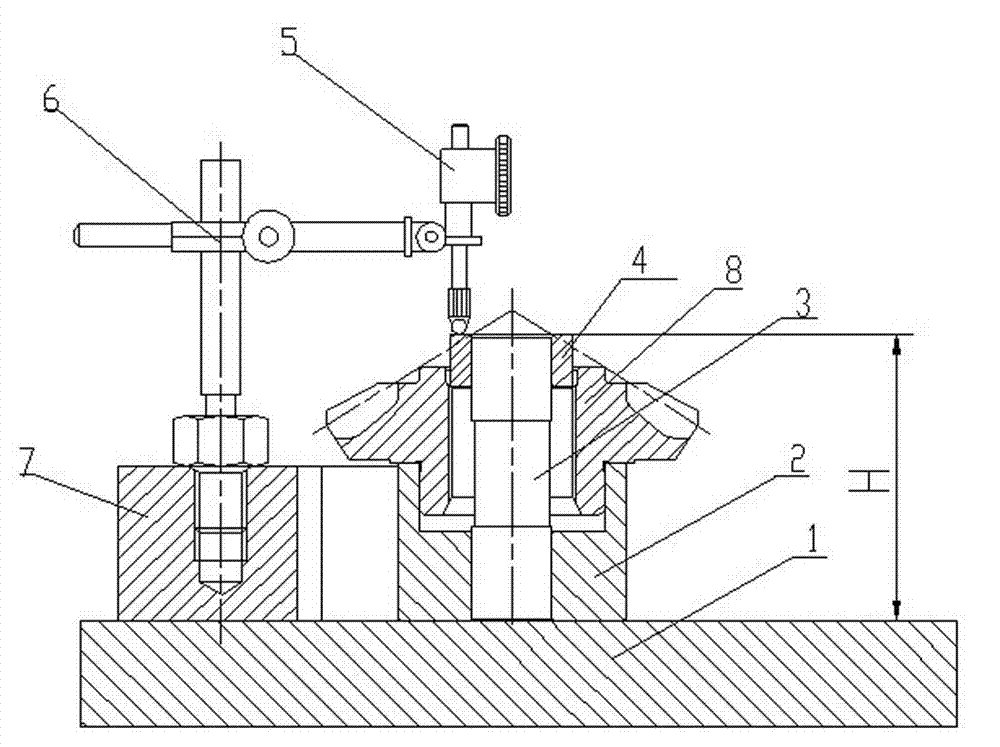

[0013] figure 1 The shown indirect measuring tool for differential bevel gear inner hole spigot angle includes a plate 1, a base 2, a mandrel 3, a positioning sleeve 4, a dial indicator 5, a gauge frame 6 and a V-shaped block 7. The flat plate 1 is a measurement reference plane in the present invention, the base 2 and the V-shaped block 7 are placed on the flat plate 1 respectively, and the V-shaped block 7 in a prone position is equipped with a positioning and measuring mechanism composed of a meter frame 6 and a dial indicator 5 . The base 2 is provided with an upward counterbore and a coaxial through hole, the upper end of the upper counterbore is parallel to the flat plate 1, the base 2 leans against the side of the positioning angle of the V-shaped block in a lying position, and is positioned and installed in the center of the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com