Force measurement type online grain water sensing device

A technology of grain moisture and sensing devices, which is applied in the direction of material resistance, etc., can solve the problems of high requirements for the measured grain and measurement environment, inaccurate measurement, and high processing difficulty, and achieve stable and reliable signal transmission, high-precision measurement, and easy Processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

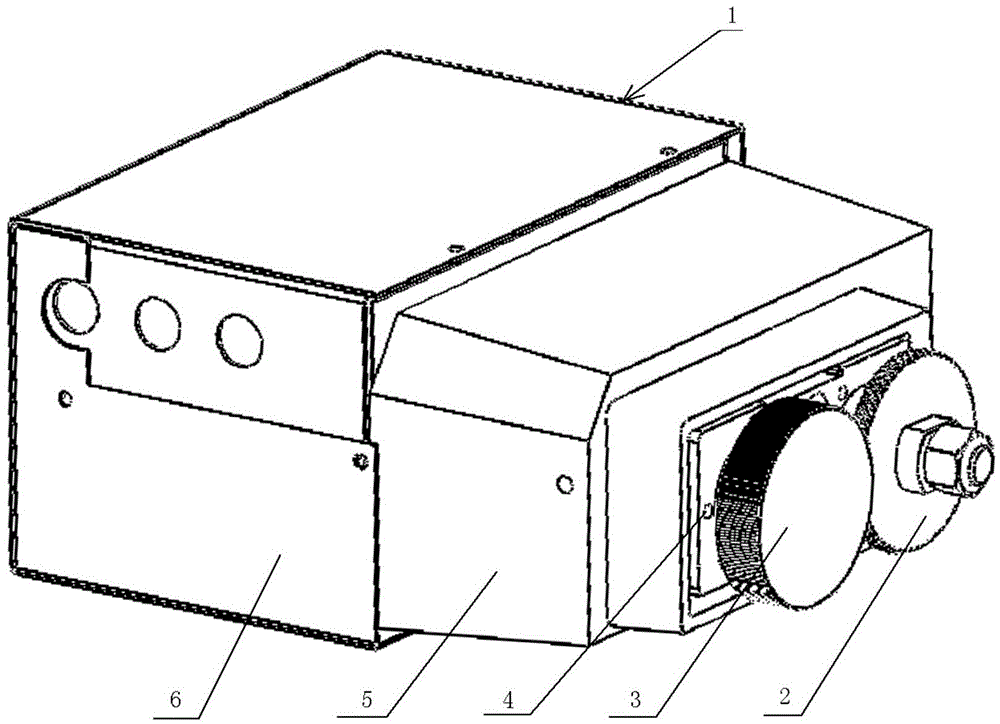

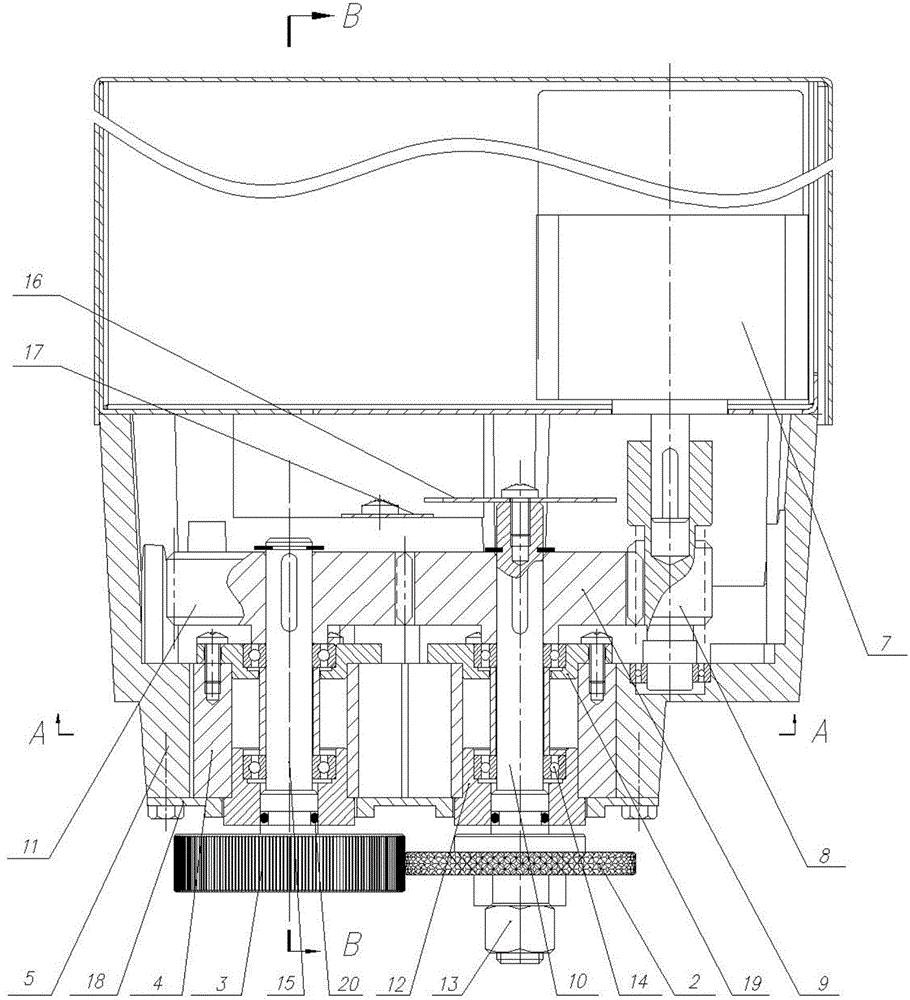

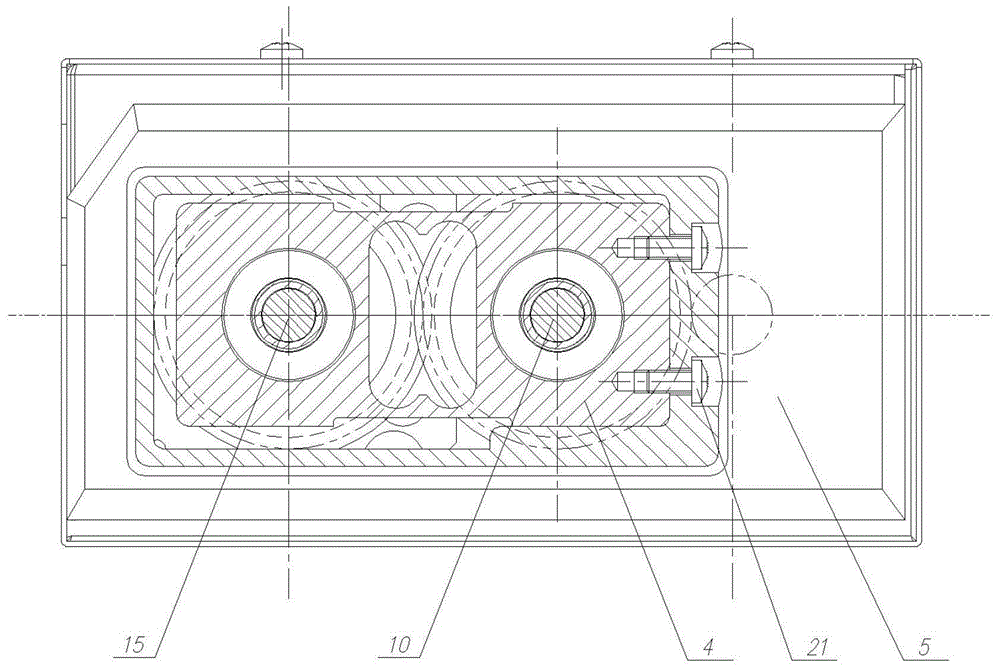

[0028] As shown in the figure, the load-measuring online grain moisture sensor device involved in the present invention includes a housing 1, the housing 1 is formed by connecting a front housing 5 and a rear housing 6, and the rear housing The body 6 is formed by connecting the outer motor casing 601 and the inner motor casing 602 inserted into the outer motor casing 601 through screws, and the inner motor casing 602 is fixedly connected with the front casing 5 through screws. A grain sampling device is provided in the front port of the body 5, and the grain sampling device includes a load cell 4 and two rollers.

[0029] The load cell 4 is fixed in the front casing 5 by screws 21 along one end surface of the longitudinal side thereof, and there is a certain gap between the other end surfaces and the inner wall of the front casing 5, so as to transmit the extrusion force, and is used to measure two The extrusion force on the grain between the rollers and the collected extrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com