Noncontact yarn tension detection system and method

A yarn tension, non-contact technology, applied in the field of engineering and technical science, can solve the problems of long integration time of area array CCD, influence on measurement accuracy, high processing difficulty, etc., and achieve low measurement environment requirements, fast spinning speed, high The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

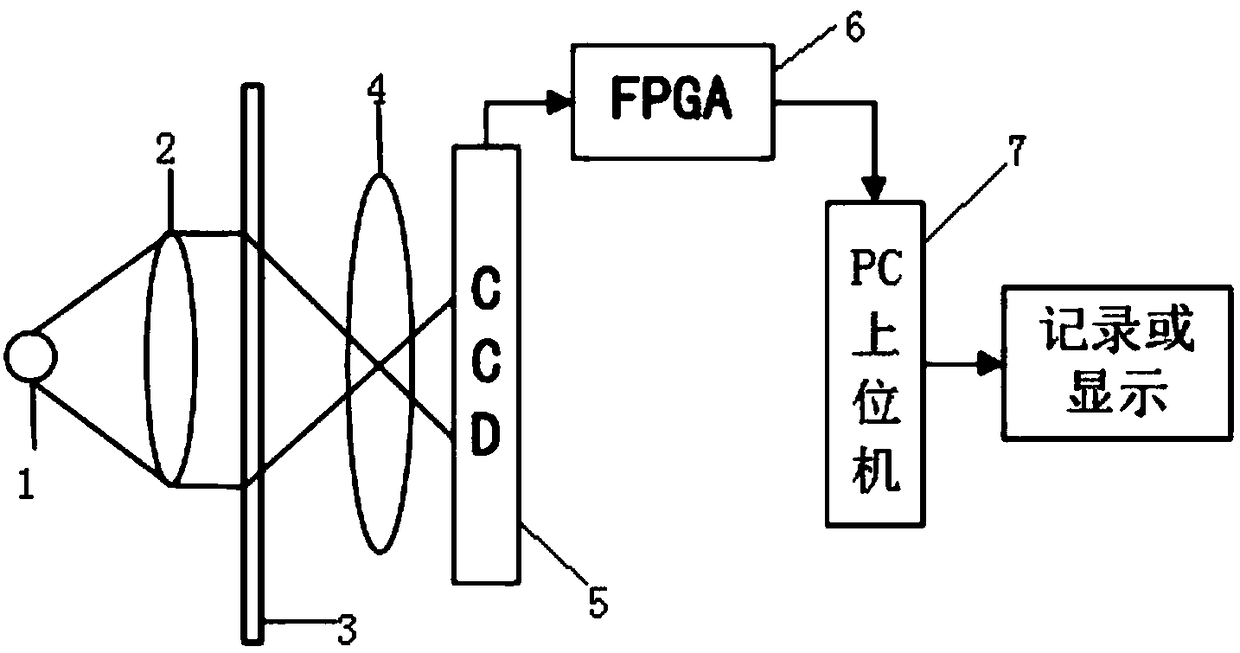

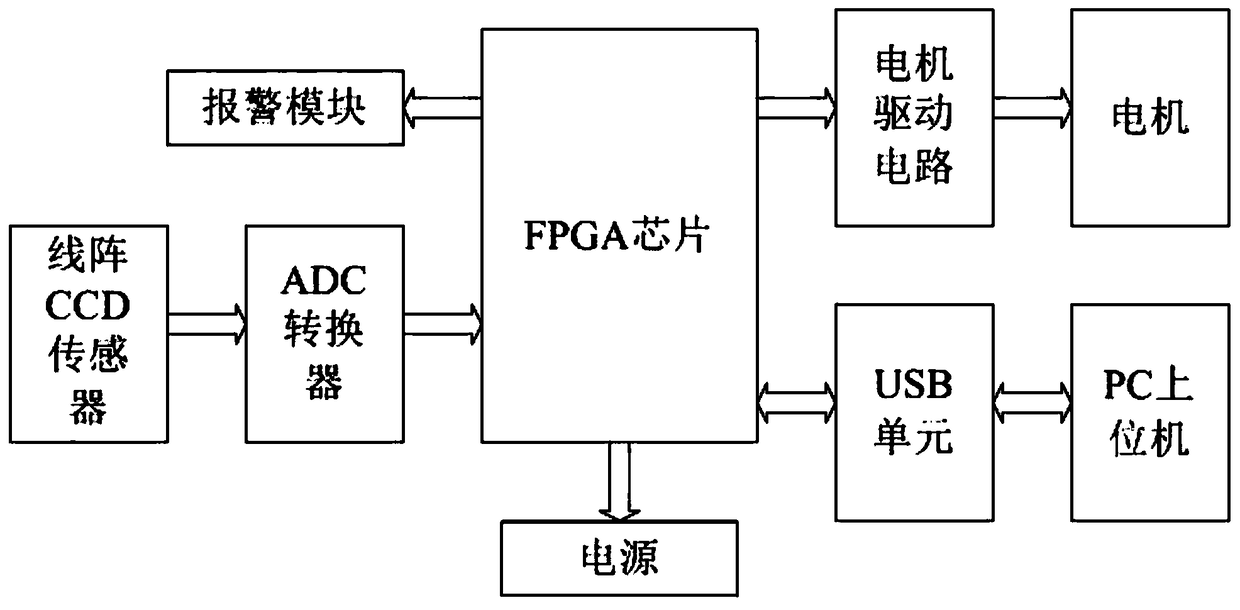

[0037] Such as figure 1 , figure 2 As shown, a non-contact yarn tension detection system of this embodiment includes a yarn guide wheel (not shown in the figure) for conducting the yarn 3, the yarn guide wheel is driven by a motor, and also includes a linear array CCD The detection head that image acquisition device forms, FPGA chip 6, the power supply that is used to supply power for FPGA chip 6, PC upper computer 7, described linear array CCD image acquisition device comprises parallel light source 1, is positioned at the passing path of parallel light source 1 successively Prism 2, imaging lens 4 and linear array CCD sensor 5, described yarn 3 passes the gap between prism 2 and imaging lens 4 and yarn 3 is para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com