Liquid refractive index CCD real-time measuring device and measuring method

A liquid refractive index, real-time measurement technology, applied in the field of optical means, can solve the problems of high requirements for measurement environment conditions, complex device system structure, large human measurement error, etc., and achieve the effect of low instrument cost, high measurement accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

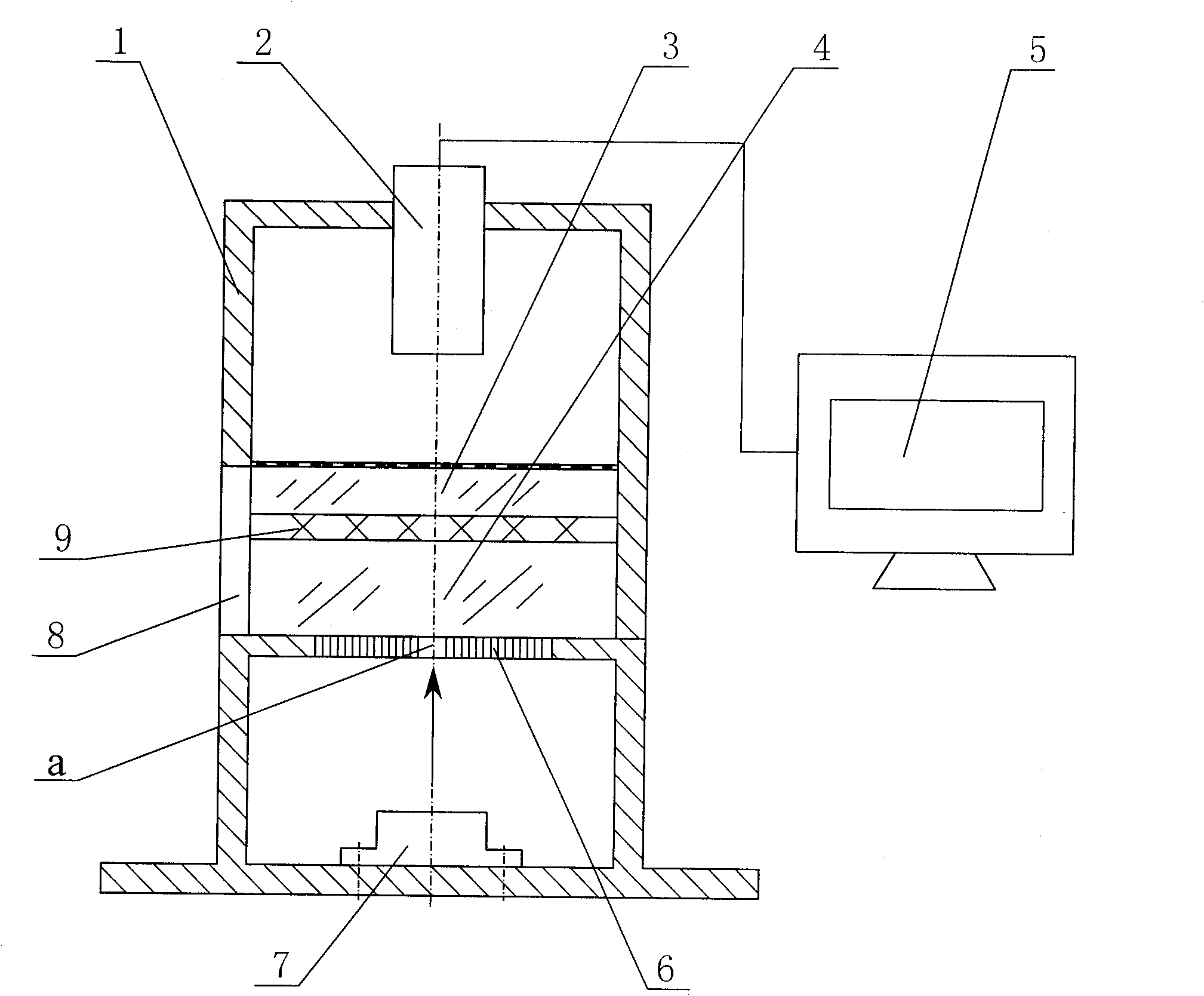

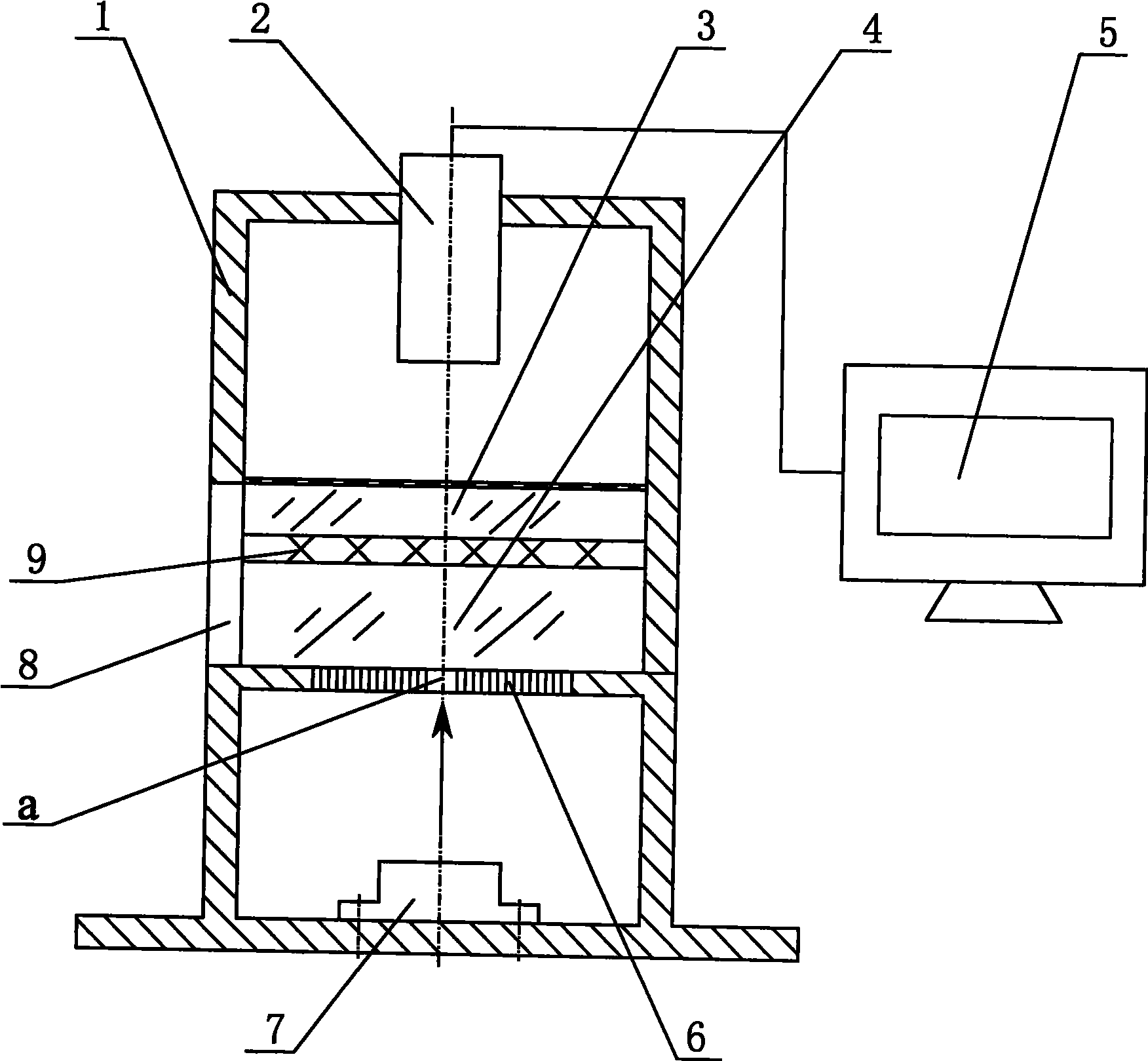

[0026] exist figure 1 Among them, the liquid refractive index CCD real-time measurement device of this embodiment is composed of a cassette 1, a CCD camera 2, a flat image display glass 3, a flat transmission glass 4, a computer 5, an aperture 6, a semiconductor laser 7, and a light shielding cover 8.

[0027] The cassette 1 of this embodiment is a stainless steel or light-tight engineering plastics cassette 1, and the lower end in the cassette 1 is fixedly connected with a semiconductor laser 7 with a threaded fastening connector, and the semiconductor laser 7 is an embodiment of a light-emitting device. Laser 7 provides the light source for the present invention. On the cassette 1, above the semiconductor laser 7 in the cassette 1, an aperture 6 is bonded with glue, and an aperture a is processed on the aperture 6. The aperture of the aperture a of the present embodiment is 1.5mm, and the aperture a of the aperture a The center line is on the same straight line as the cente...

Embodiment 2

[0040] In the present embodiment, the aperture a aperture of the diaphragm 6 bonded with glue on the cassette 1 above the semiconductor laser 7 in the cassette 1 is 0.5 mm, and the thickness h of the flat panel image display glass 3 is 6.5 mm. The size of the glass 3 is the same as that of the flat transparent glass 4, and the thickness h of the flat transparent glass 4 is 17 mm. The flat image shows that the glass 3 and the flat transparent glass 4 are H-K9 optical glass, and its refractive index n is 1.5146. The flat image shows The incident surface of the glass 3 is an optical surface, and the outgoing surface is a textured surface. The coupling relationship of other components and components is the same as that of Embodiment 1.

[0041] The liquid refractive index CCD real-time measuring device of this embodiment is used to measure the refractive index of distilled water and absolute ethanol at room temperature (20° C.), and compare it with the standard refractive index of...

Embodiment 3

[0046] In the present embodiment, the aperture a aperture of the diaphragm 6 bonded with glue on the cassette 1 above the semiconductor laser 7 in the cassette 1 is 2mm, and the thickness h of the flat image display glass 3 is 3mm, and the flat image display glass 3 The size of the flat transparent glass 4 is the same as that of the flat transparent glass 4. The thickness h of the flat transparent glass 4 is 8mm. The flat image shows that the glass 3 and the flat transparent glass 4 are H-K9 optical glass, and its refractive index n is 1.5146. The flat image shows that the glass The incident surface is an optical surface, and the outgoing surface is a textured surface. The coupling relationship of other components and components is the same as that of Embodiment 1.

[0047] The liquid refractive index CCD real-time measuring device of this embodiment is used to measure the refractive index of distilled water and absolute ethanol at room temperature (20° C.), and compare it wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminous intensity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com