Measuring method for form and position tolerance

A form and position tolerance and measurement method technology, which is applied to measurement devices, instruments, electrical devices, etc., can solve the problems of low precision, damage to the surface of parts, low efficiency, etc., and achieve simple measurement operation, low cost, and measurement environment. less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

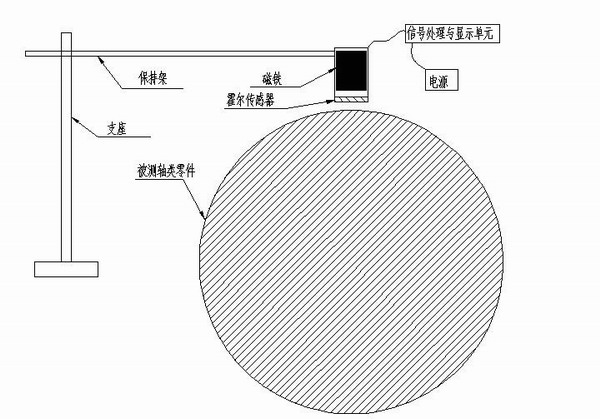

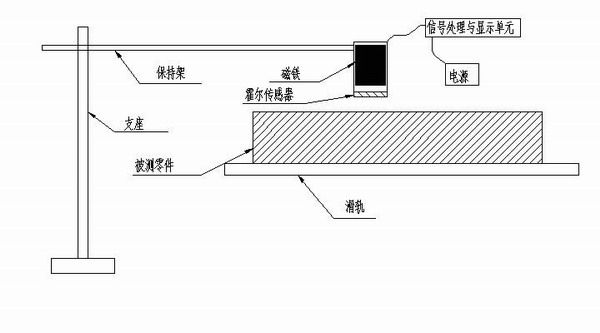

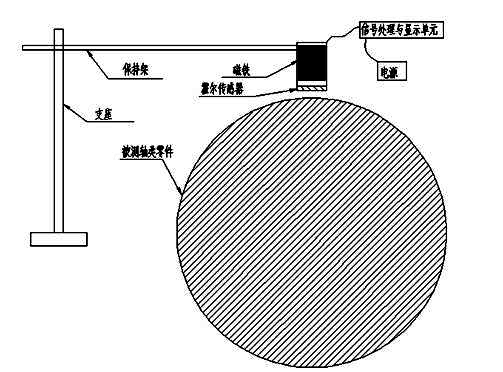

[0028] Method 1: if figure 1 As shown, a radial circular runout measurement device based on Hall sensors. Including support, cage, sensor, signal processing and display unit, power supply. Among them, the Hall sensor is a linear output sensor, and the magnet is a neodymium iron boron magnet. The magnet is cylindrical, with a diameter of 4-10mm and a length of 10-20mm. The power supply uses dry batteries to supply power for the signal processing and display unit, and a constant current source circuit is connected to supply power for the sensor, and the voltage and current are selected according to the power supply requirements of the sensor. The magnetic steel and the sensor are installed in a plastic casing, and adjusting screws are installed on the casing to fine-tune the positions of the magnetic steel and the sensor. Adjust the distance between the magnetic steel and the sensor to 1-2mm, and calibrate according to the calibration steps. If necessary, turn the adjusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com