Dual-surface metal waveguide measuring method and its device

A double-sided metal and measuring device technology, which is applied in the field of physical measurement, can solve the problems of affecting the accuracy of measurement results, difficult to adjust the distance accurately, and limiting the measurement range, etc., and achieve the effects of short measurement cycle, easy operation and high measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

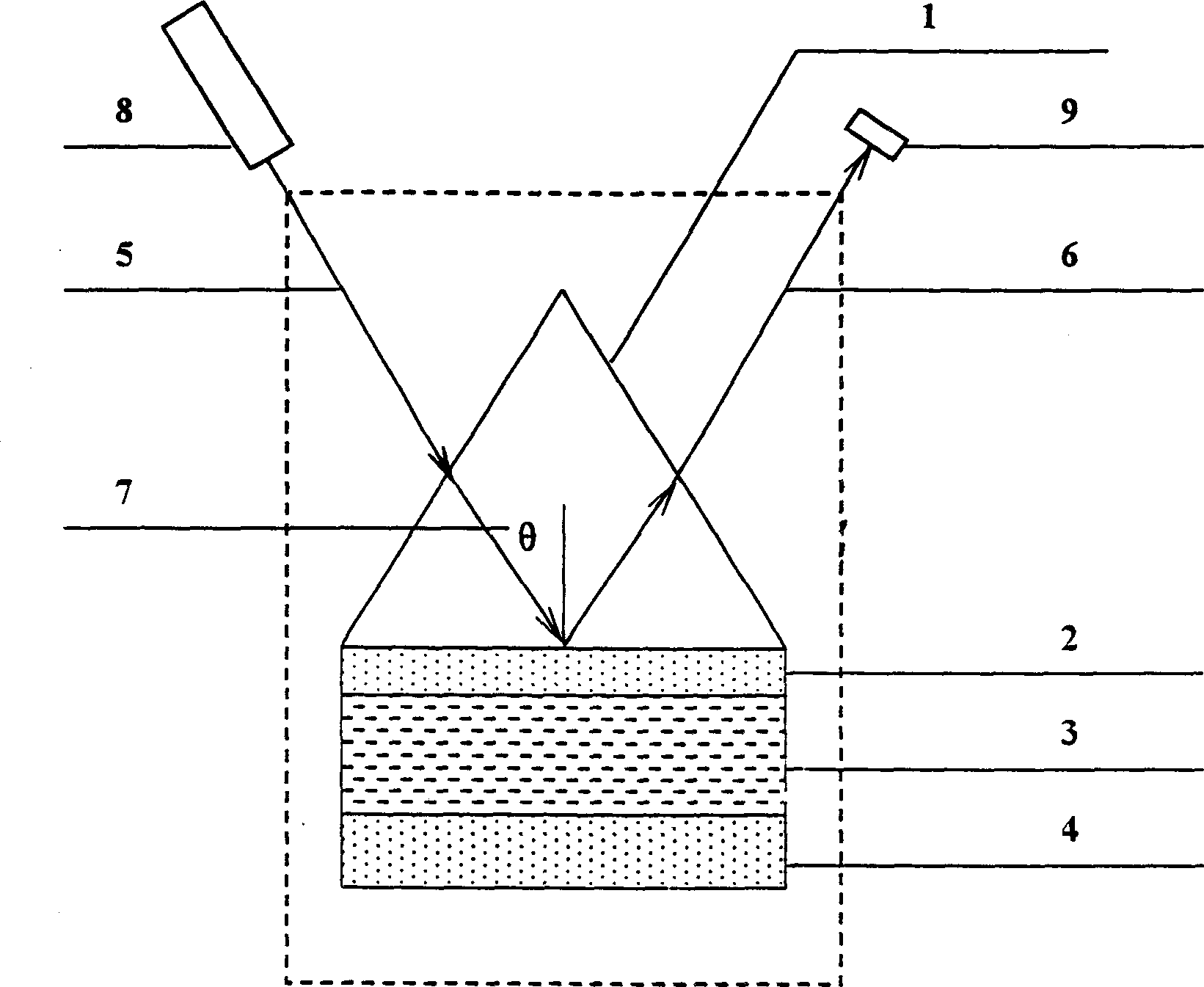

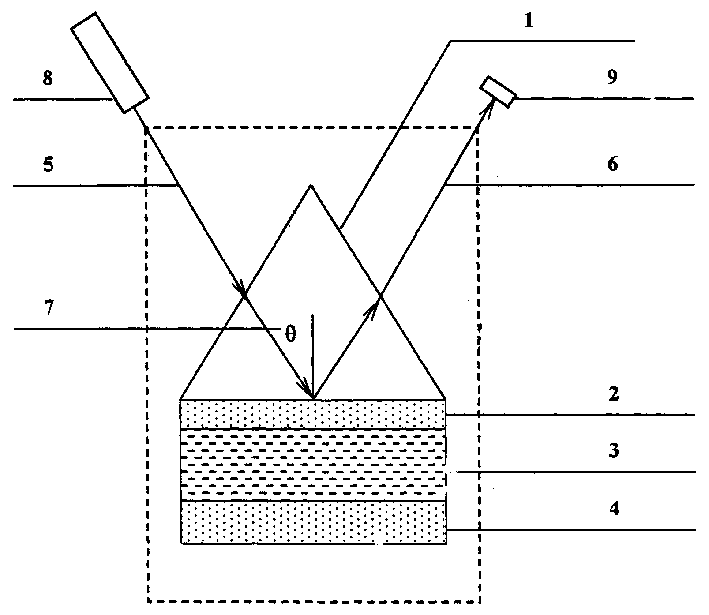

Embodiment 1

[0035] The first step: the coupling device 1 selects a high-refractive-index equilateral triangular prism (n=1.5), adopts the sputtering method to plate a metal film layer on the bottom surface of the prism and the substrate material, and then puts the two film layers together, and in between A thin layer of air is left to form a double-sided metal waveguide structure. The thickness of the upper metal film 2 is 34nm, the film 3 to be tested is air, the actual value of the thickness is 5μm, and the actual value of the refractive index is 1.0 (dielectric coefficient is 1.0). The metal film 4 has a thickness of 300nm, and the metal is gold (ε=-14.4+i1.22 at a wavelength of 690.0nm);

[0036] The second step: select the incident laser 5 with a wavelength of 690.0nm, the incident light is a transverse magnetic wave (TM mode), and the incident angle 7 is scanned between 0 and 90 degrees;

[0037] Step 3: Receive and measure the light intensity of the laser beam 6 reflected from the ...

Embodiment 2

[0050] The first step: the coupling device 1 selects a high refractive index equilateral rutile prism (n=2.8), and adopts sputtering method to form a double-sided metal waveguide structure on both sides of the film to be tested. The thickness of the upper metal film 2 is 48nm, and the film to be tested 3 It is lithium niobate, the actual value of the thickness is 0.5 μm, the actual value of the refractive index is 2.22 (dielectric coefficient is 4.9284), and the thickness of the lower metal film 4 is 300 nm. The metal is silver (ε=-12.0+i0.4 at a wavelength of 560.0 nm).

[0051] The second step: select the incident laser wavelength 5 to be 560.0nm, the incident light is a transverse magnetic wave (TM mode), and the incident angle 7 is scanned between 0 and 90 degrees;

[0052] Step 3: Receive and measure the light intensity of the laser beam 6 reflected from the bottom surface of the prism on the other side of the prism. The minimum value of the reflected light intensity is t...

Embodiment 3

[0065] Step 1: This example does not use the coupling device 1, but uses the air direct coupling method to excite the guided mode (n=1.0), and uses the sputtering method to form a double-sided metal waveguide structure on both sides of the film to be tested, and the thickness of the upper metal film 2 34nm, the real value of the thickness of the film 3 to be measured is 1000 μm, the real value of the refractive index is 1.673 (dielectric coefficient is 2.8), the thickness of the lower metal film 4 is 300nm, and the metal adopts gold (ε=-34.5+i under the wavelength of 890.0nm .47).

[0066] The second step: select the incident laser 5 with a wavelength of 890.0nm, the incident light is a transverse magnetic wave (TM mode), and the incident angle 7 is scanned between 0 and 90 degrees;

[0067] Step 3: Receive and measure the light intensity of the laser beam 6 reflected from the bottom surface of the prism on the other side of the prism. The minimum value of the reflected light ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com