Visual inspection method and system for three-dimensional bent pipe

A technology of visual inspection and pipe bending, applied in 3D image processing, image data processing, instruments, etc., can solve the problems of limited measurement range, not enough portability, large mold volume and inconvenient storage, etc. The data can be quantified and the effect of meeting the requirements of point cloud acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

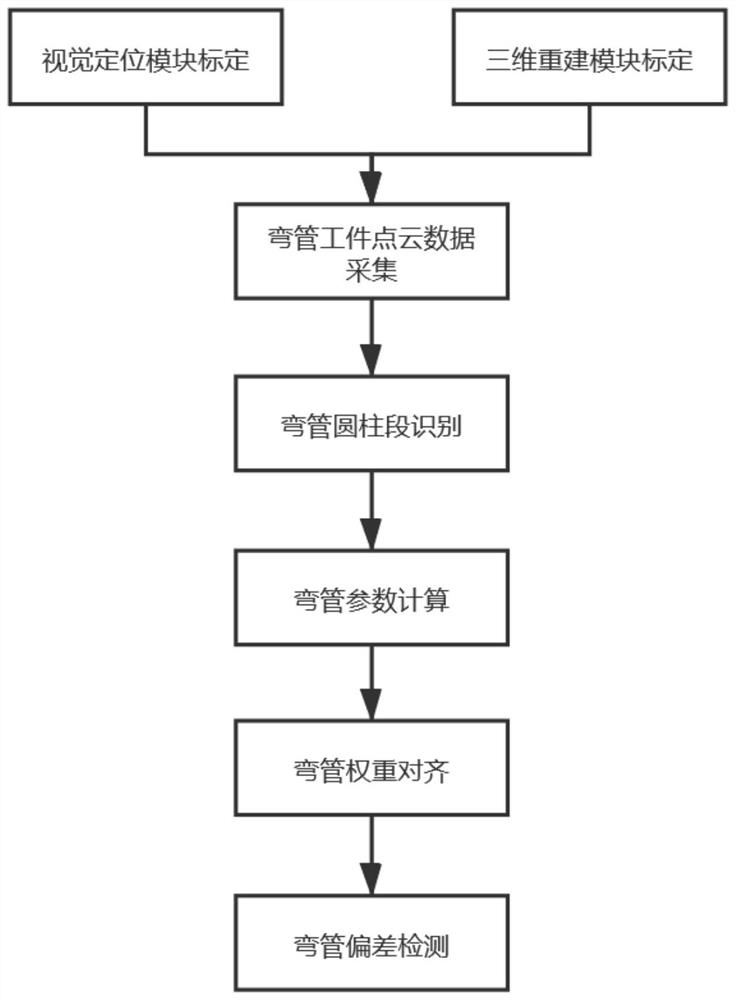

[0065] The process flow of the three-dimensional curved pipe visual inspection method in an embodiment of the present invention is as follows: figure 1 shown.

[0066] refer to figure 1 , an embodiment of the present invention provides a visual detection method for a three-dimensional bent pipe, comprising the following steps:

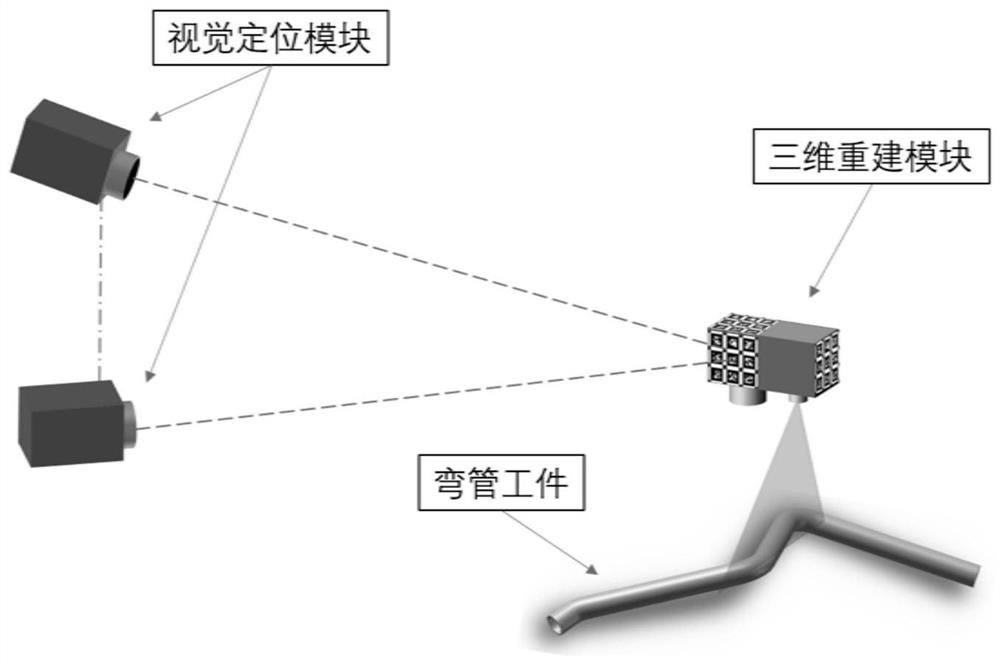

[0067] Step S1, calibration of the visual positioning module: arrange a calibration object in the visual positioning field of view, and perform global calibration on the internal parameters and external parameters of the camera in the positioning module, and the calibration object includes circular coded points and circular non-coded points;

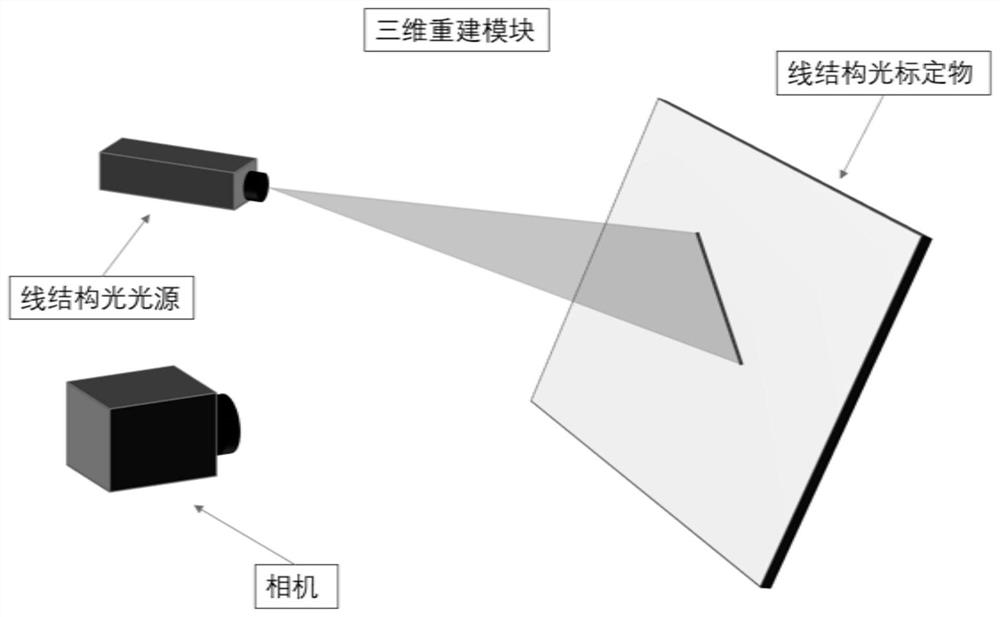

[0068] Step S2, calibration of the 3D reconstruction module: arrange calibration ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com