Calibration device for detecting vacuum gauges with relative errors of indicating values no less than 30%

A technology of relative error and calibration device, applied in the direction of measuring device, measuring fluid pressure, instruments, etc., can solve the problems of inability to perform calibration at any time, inconvenient production, errors, etc., and achieve the effect of low measurement environment requirements, low cost, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

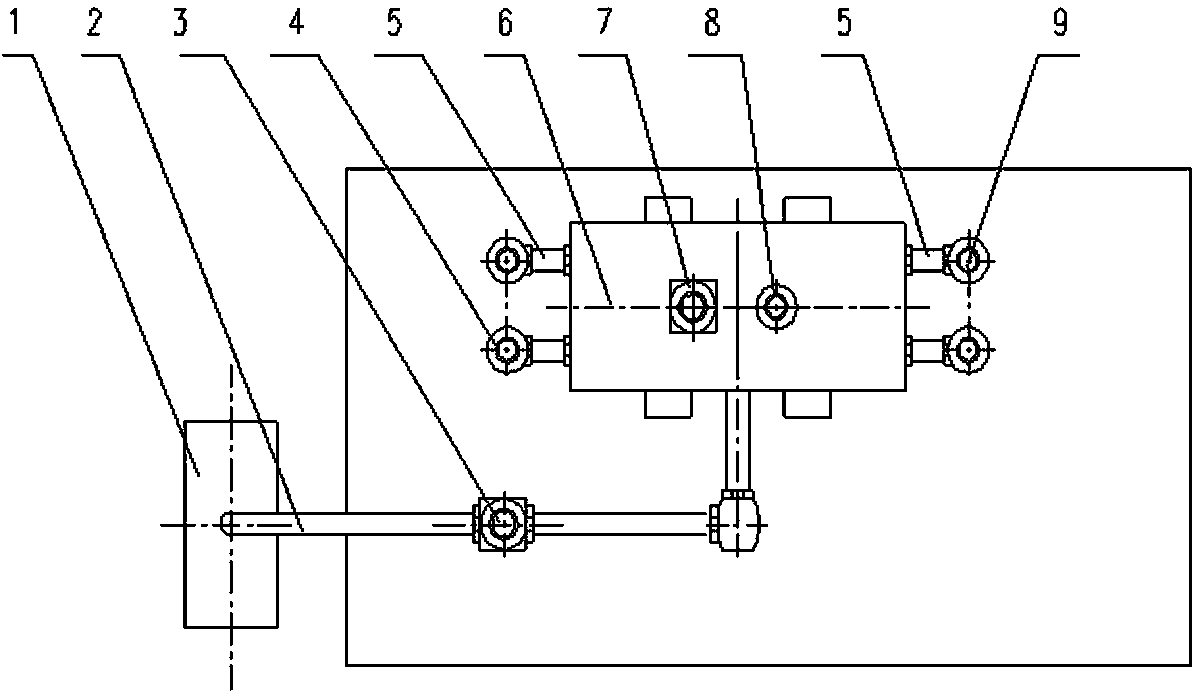

[0016] Such as figure 1 As shown, the present invention includes a vacuum pump 1, a standard vacuum gauge 4, a calibrated vacuum gauge 9, a calibration chamber 6 and a connecting pipe 5. The shape of the calibration chamber 6 is a cylinder with a height-to-inner diameter ratio of 1 to 3 / 1, two connecting pipes 5 are welded at both ends of the calibration chamber 6, and a valve 7 is welded in the middle of the side of the calibration chamber 6 , fine-tuning valve 8 and the connection interface, the connection interface is connected with the vacuum pump 1 through the pipeline 2, and the control valve 3 is arranged on the pipeline 2. The standard vacuum gauge 4 and the calibrated vacuum gauge 9 are respectively installed at the port of the connecting pipe 5 .

[0017] The principle of the present invention is as follows: the present invention adopts the principle of dyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com