Photoelectric liquid level sensor and measuring method thereof

A liquid level measurement and sensor technology, applied in liquid/fluid solid measurement, using optical devices to transmit sensing components, measuring devices, etc., can solve the problem of being easily affected by external factors, requiring high external environments, and prone to mechanical failures and other problems, to achieve the effect of compact mechanism, small volume and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

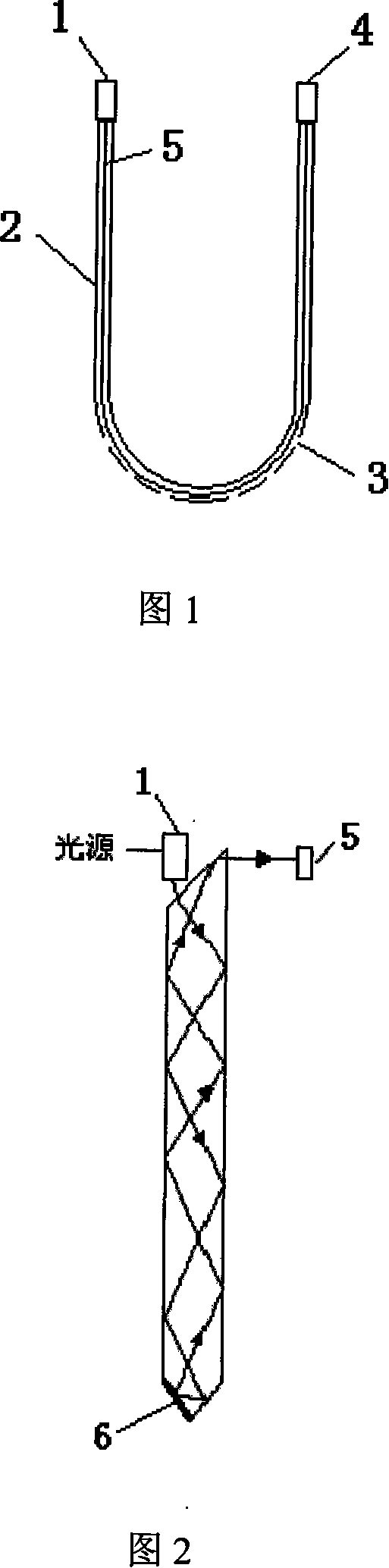

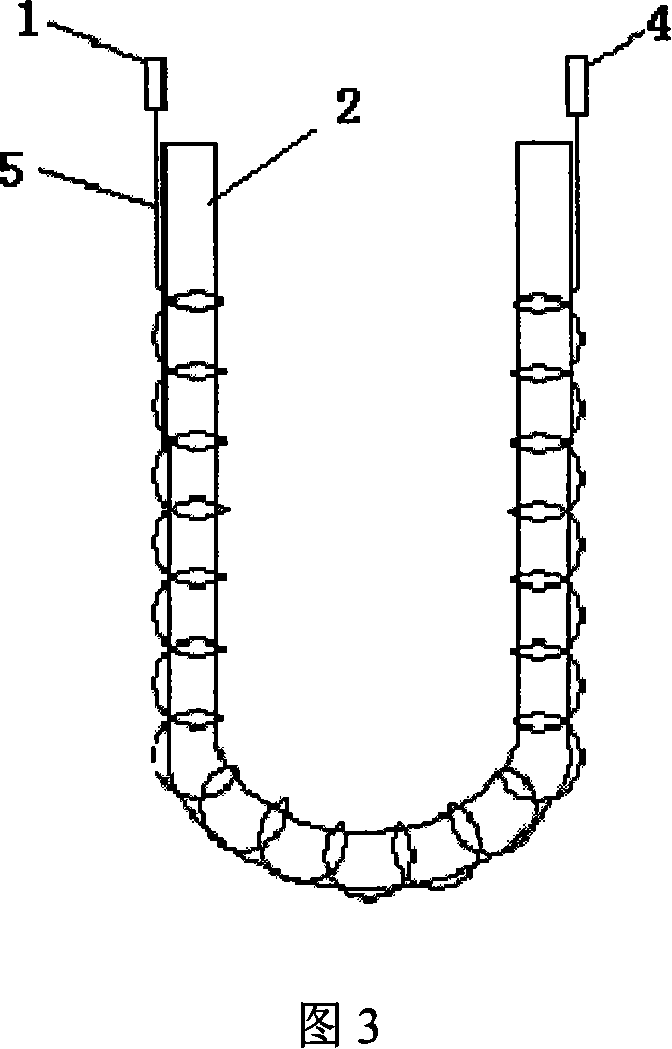

[0013] The present invention is shown in principle schematic diagram 1, FIG. 2 and FIG. 3 of the photoelectric liquid level sensor. The principle is to bend a section of optical fiber into an arc shape with a certain radius of curvature and immerse it in liquid. When the outside of the light transmission medium changes from air to liquid, the total reflection condition of part of the light inside the light transmission medium (optical fiber) is destroyed, so The beam in the light-transmitting medium in the liquid partially overflows, causing a change in the intensity of the outgoing light.

[0014] Due to the divergence of the light source beam, refraction and reflection occur on the surface of the light transmission medium, and total reflection occurs at the bottom of the triangular pyramid. Since the liquid destroys the total reflection condition of part of the light inside the light transmission medium (optical fiber), the light transmission in the liquid Part of the light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com