Material performance testing device and material performance testing system

A technology for material properties and testing devices, used in measurement devices, analytical materials, thermal development of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

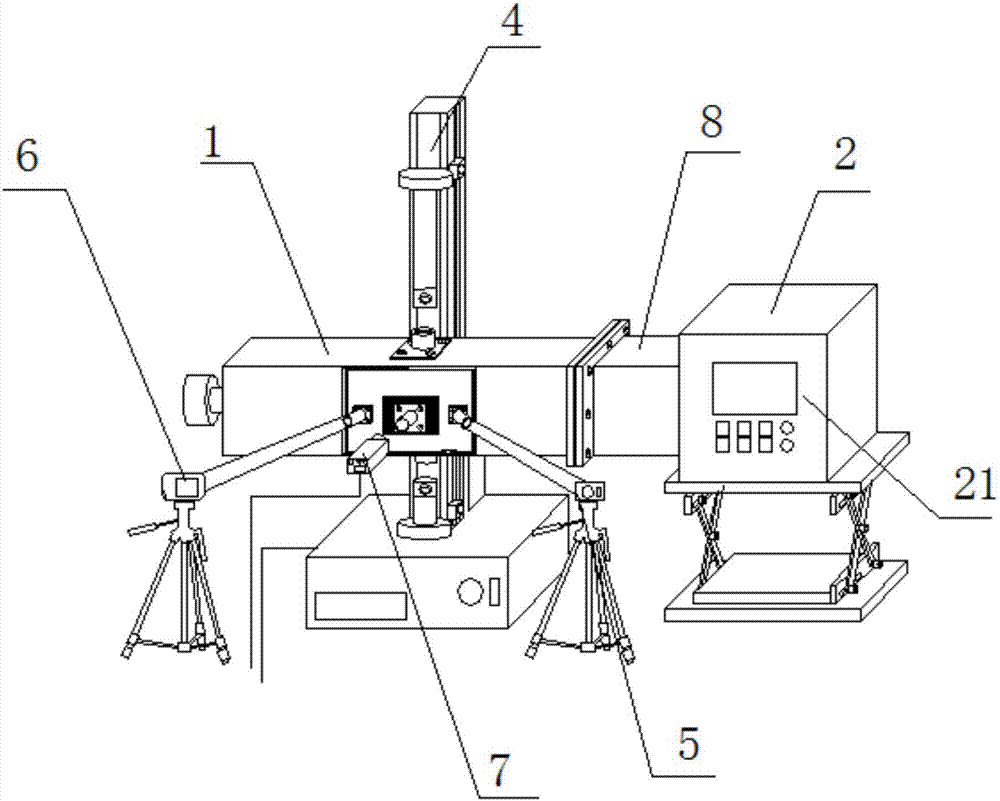

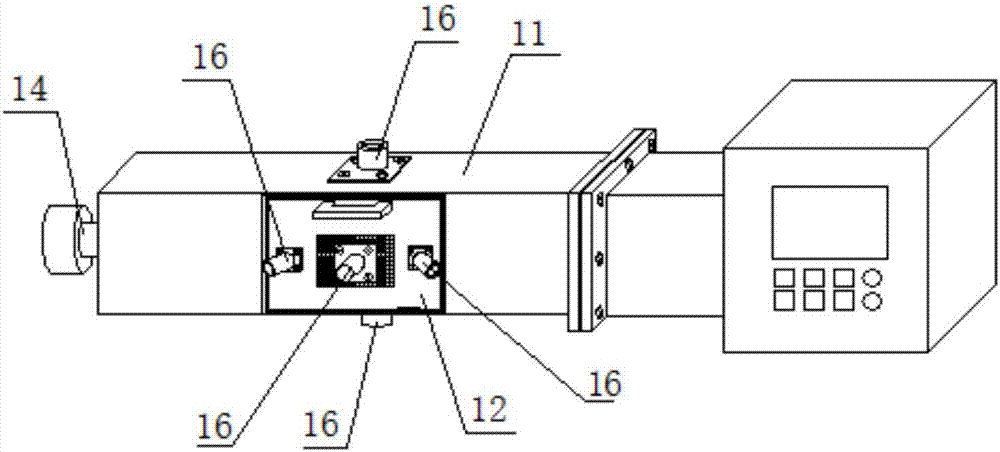

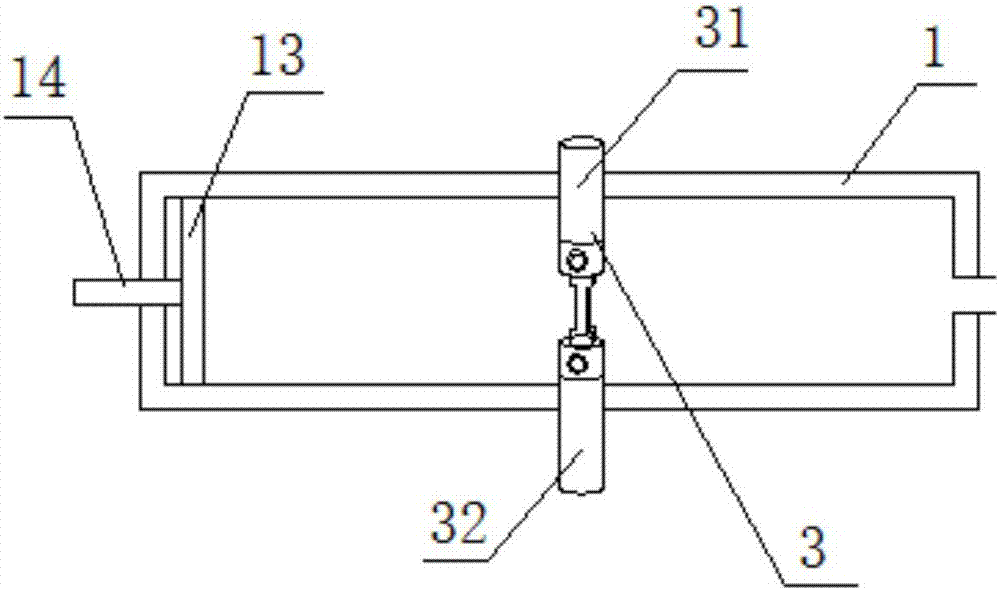

[0045] see figure 1 , figure 2 and image 3 This embodiment 1 provides a material performance testing device, including a heat treatment chamber 1 , a microwave source 2 , a control module 21 , a clamping device 3 , a mechanical loading device 4 , a light source 5 , an infrared thermal imager 6 and a camera 7 .

[0046] Wherein, the microwave source 2 is connected to the heat treatment cavity 1, and the microwave source 2 is used to provide microwaves to the cavity of the heat treatment cavity 1; the microwave source 2 is electrically connected to the control module 21; The heat treatment chamber 1 is provided with five through holes, and the through holes include a first through hole, a second through hole, a third through hole, a fourth through hole and a fifth through hole; the heat treatment chamber 1 It includes a cavity body 11 and a sliding door 12; the cavity body 11 is provided with an opening, the sliding door 12 is arranged at the opening of the cavity body 11, a...

Embodiment 2

[0066] Correspondingly, see Figure 5 and Figure 6 , the present embodiment 2 provides a material performance testing system, which includes the material performance testing device involved in the above-mentioned embodiment 1 (the specific structure of the material performance testing device will not be repeated one by one), and it also includes a mechanical sensor 41 and a computer 9; wherein, the mechanical sensor 41 is arranged on the mechanical loading device 4; the computer 9 is electrically connected to the mechanical sensor 41, the thermal imaging camera 6 and the camera 7 respectively.

[0067] Obviously, when the mechanical loading device 4 provides tension or pressure to the material to be tested, the mechanical sensor 41 arranged on the mechanical loading device 4 will sense this change; after the mechanical sensor 41 senses this change of the mechanical loading device 4, Will want computer 9 to send start-up signal; After computer 9 receives the start-up signal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com