Radial pulsation measurement instrument for external spline gear ring

A technology of radial runout and external splines, applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve problems such as low efficiency, roundness error, and low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

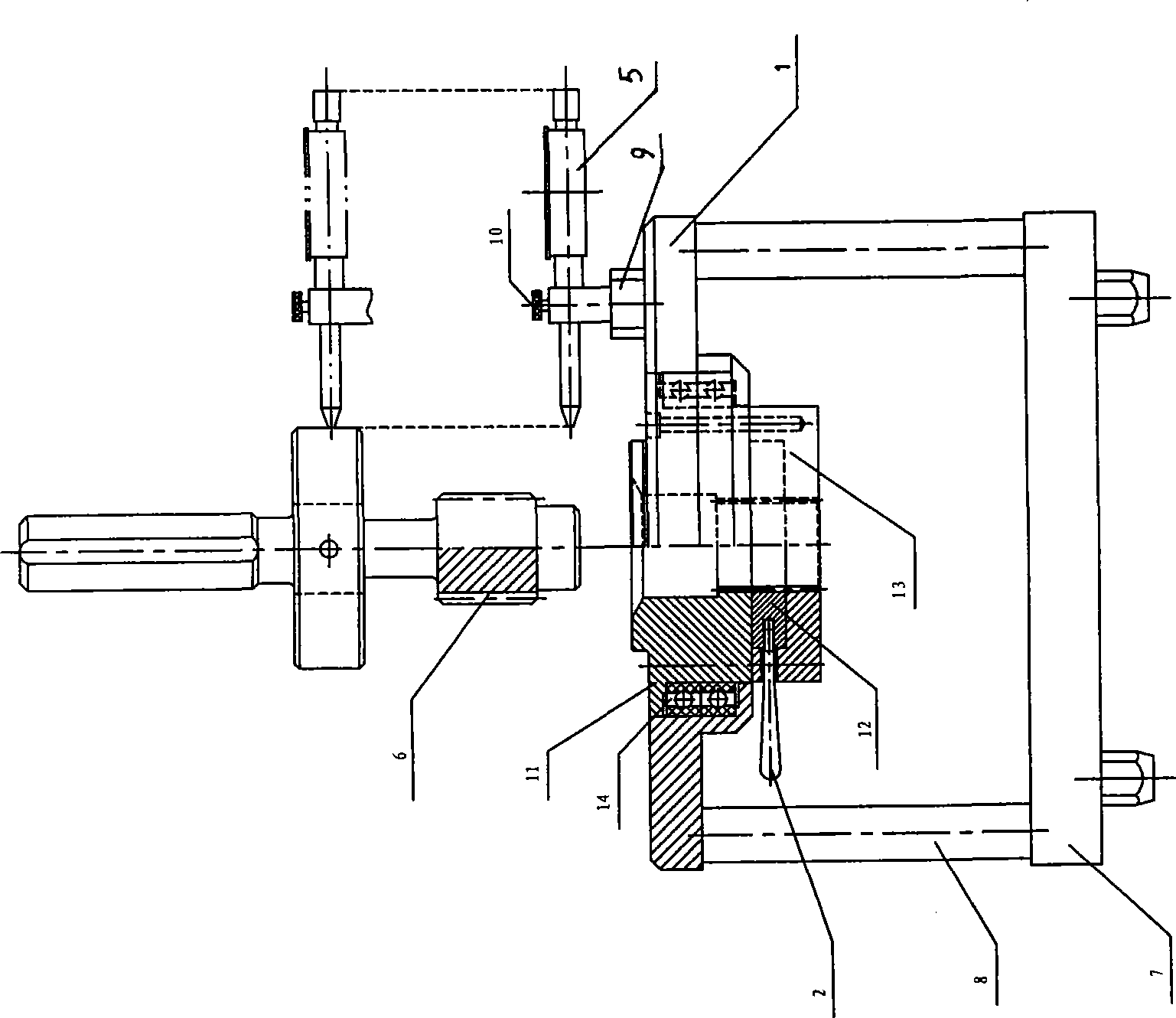

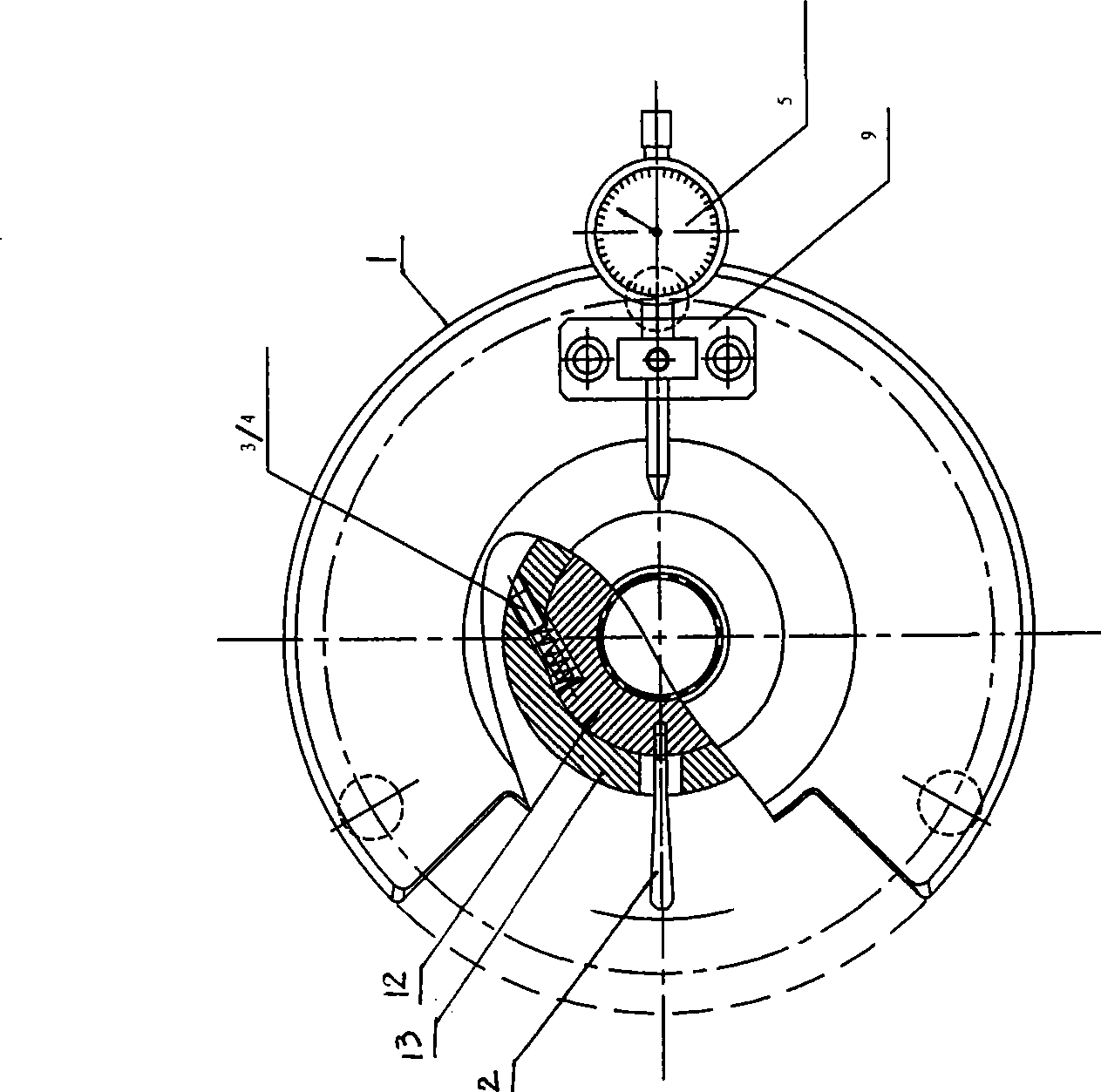

[0010] Such as figure 1 and figure 2 As shown, the radial runout measuring instrument of the present invention with external splined ring gear includes a measuring table 1, an internal splined ring, an adjusting handle 2, an adjusting screw 3, a compression spring 4, a scale 5, a calibration piece 6, a base plate 7 and The support column 8 and the gauge 5 adopt a dial indicator, which is connected on the measuring platform 1 through the table base 9 and the nail screw 10. The measuring table 1 is supported on the bottom plate 7 by the support column 8 . The inner spline ring is installed on the measuring table 1 through a precision bearing 14, and it can rotate concentrically at will. The inner spline ring is assembled by spline one 11, spline two 12, spline three 13 and three coaxial inner splines. The first spline 11 and the third spline 13 are fixed together, the tooth shapes of the two splines are completely corresponding, and they cannot move relative to each other. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com