Measuring method for silicon sheet binding strength

A technology of bonding strength and measurement method, which is used in measurement devices, testing material strength by applying stable shear force, special data processing applications, etc. Measurement environment requires advanced issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

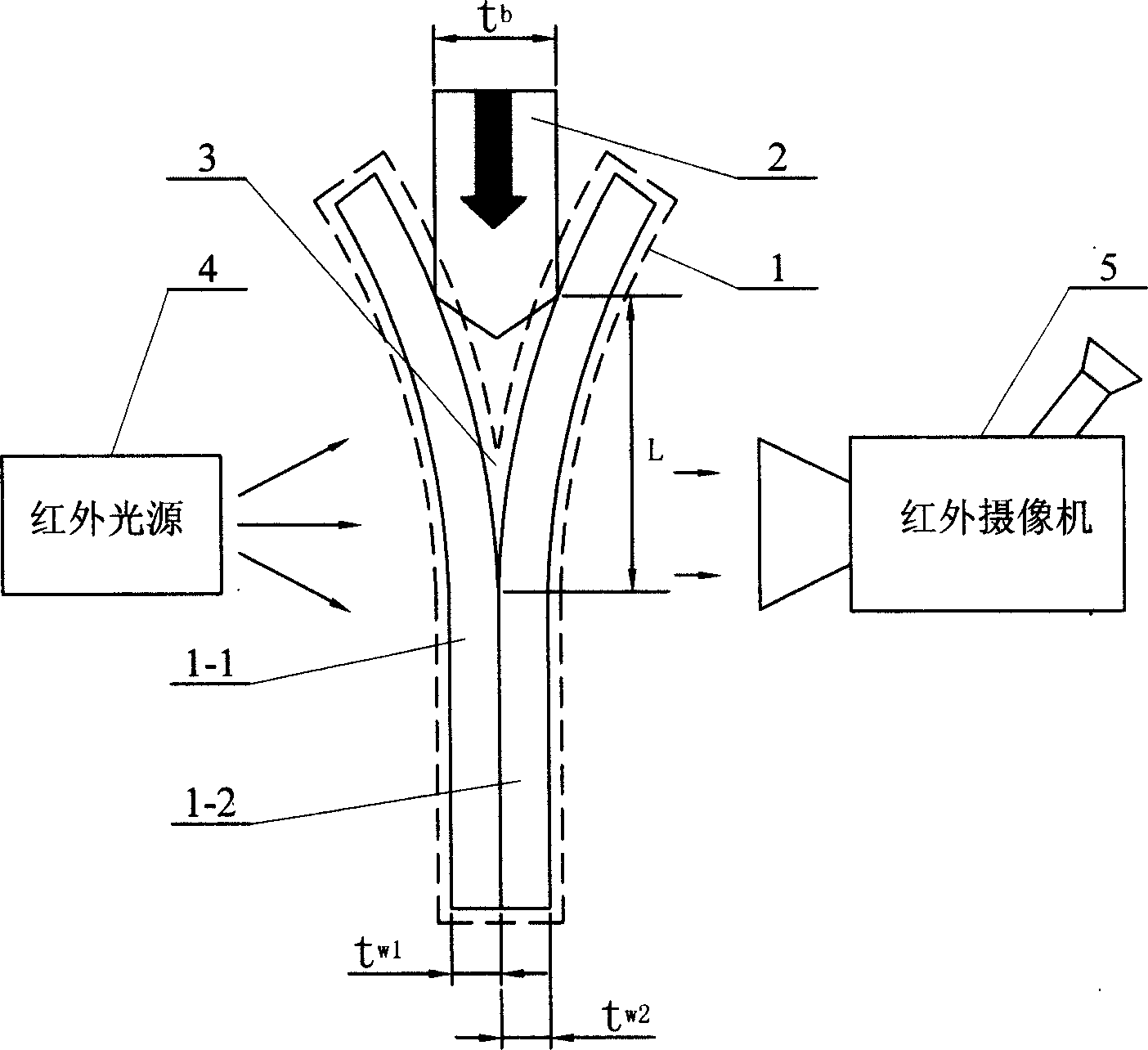

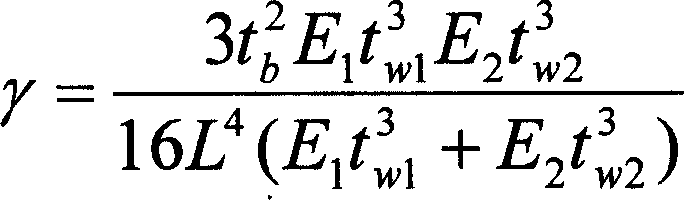

[0005] Specific implementation mode one: combine figure 1 Illustrate present embodiment, its measurement step is: measure the thickness t of wafer 1-1 in bonding silicon wafer 1 respectively w1 , the thickness t of wafer 1-2 w2 001; insert the blade 2 into the bonding surface of the wafer 1-1 and the wafer 1-2 at a constant speed, and insert the edge of the blade 2 into the bonding surface completely, and partly separate the wafer 1-1 from the wafer 1-2; Thickness t b 100 μm ~ 230 μm; the blade line of the blade 2 is parallel to the bonding surface of the wafer 1-1 and the wafer 1-2 002; the length value L 003 of the crack 3 in the separation part of the wafer 1-1 and the wafer 1-2 is measured, and its measurement method Yes: according to the transmission characteristics of the infrared spectrum, one side of the silicon wafer 1 is irradiated with an infrared light source 4, and the length value L of the crack 3 is measured on the other side of the silicon wafer 1 through an...

specific Embodiment approach 2

[0007] Specific implementation mode two: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is that in step 002, the thickness t of the blade 2 b is 120 μm.

specific Embodiment approach 3

[0008] Specific implementation mode three: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is that in step 002, the thickness t of the blade 2 b is 160 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com