Automatic measuring apparatus and measuring method of multifunctional mobile phone backboard

An automatic measurement and multi-function technology, applied in measurement devices, instruments, etc., can solve the problems of long measurement process, high testing environment requirements, low measurement efficiency, etc., to meet the needs of large-scale testing, low measurement environment requirements, automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

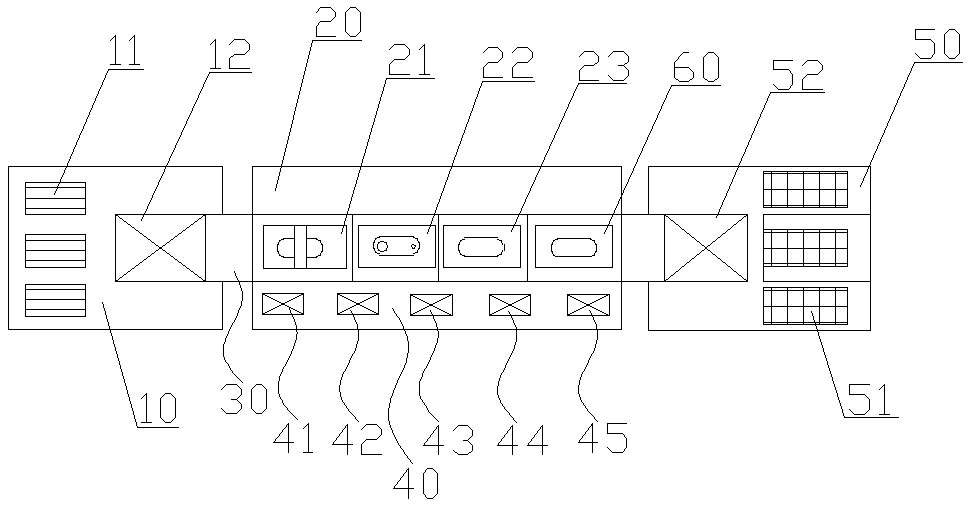

[0028] figure 1 It shows a structural schematic diagram of an embodiment of the multi-functional mobile phone backplane automatic measurement device of the present invention, and is also a schematic diagram of a preferred embodiment. Such as figure 1 The multifunctional mobile phone back panel automatic measuring device shown includes a feeding unit 10, a multifunctional measuring unit 20, a conveying unit 30, a material shifting unit 40, a feeding unit 50, and a control unit (not shown in the figure), wherein: The loading unit 10 includes a plurality of loading boxes 11 and a loading manipulator 12, a plurality of the loading boxes 11 are used for placing samples to be tested, and the loading manipulator 12 is used for loading the samples to be tested in the loading boxes To the conveying unit 30; the multifunctional measuring unit 20 is arranged on one side of the feeding unit, and is used for multifunctional measurement of the sample to be tested in the feeding unit; the c...

Embodiment 2

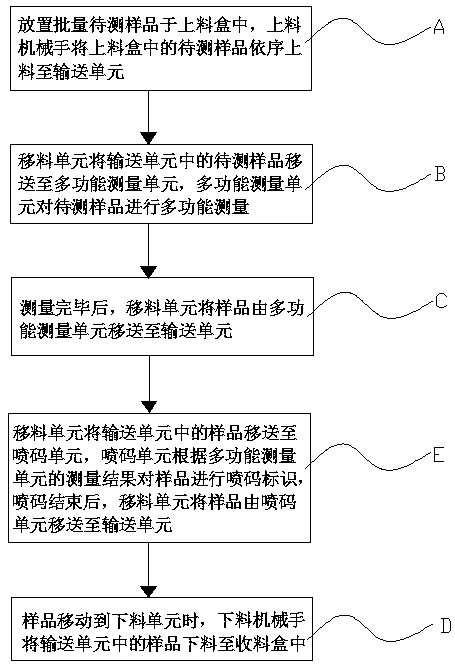

[0034] This embodiment provides a method for automatic measurement of the backplane of a multifunctional mobile phone, such as figure 2 As shown, it mainly includes the following steps:

[0035] Step A. Place batches of samples to be tested in the loading box, and the loading manipulator sequentially loads the samples to be tested in the loading box to the conveying unit, and the samples to be tested are driven by the conveying unit to move to the rear end of the conveying unit;

[0036] Step B, when the sample to be tested is moved to the multifunctional measuring unit, the material transfer unit transfers the sample to be tested in the conveying unit to the multifunctional measuring unit, and the multifunctional measuring unit performs multifunctional measurement of the sample to be tested;

[0037] Step C. After the measurement is completed, the material transfer unit transfers the sample from the multifunctional measuring unit to the conveying unit, and the sample moves t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com