Device and method for detecting thermally induced straightness-perpendicularity errors of horizontal machining center

A machining center and error detection technology, applied in measuring devices, electromagnetic measuring devices, electrical devices, etc., can solve problems such as poor adaptability, errors, high costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] For the convenience of readers to further understand the content of the invention, features and specific usage of the present invention, the specific implementation cases of the present invention will be described in detail below in conjunction with the accompanying drawings:

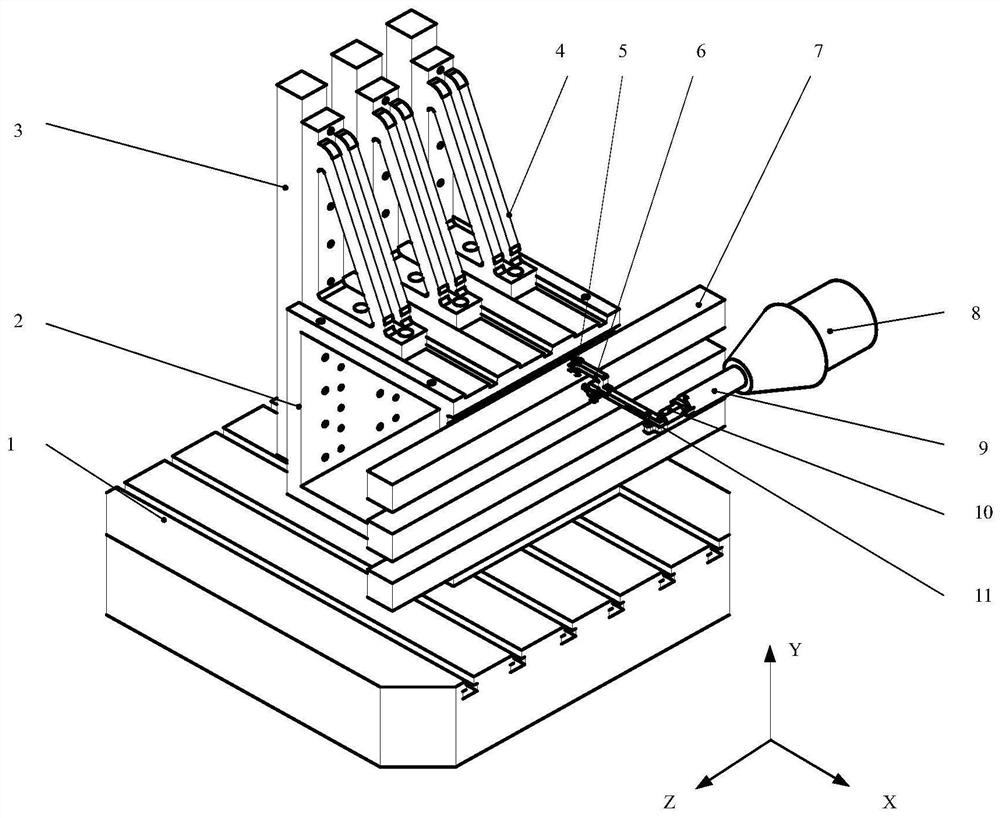

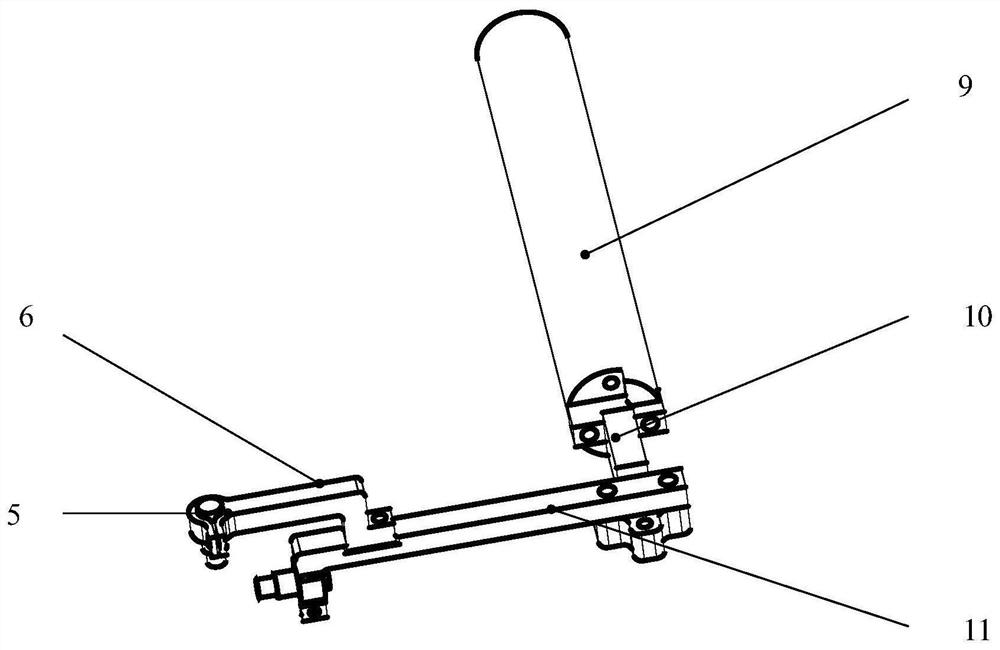

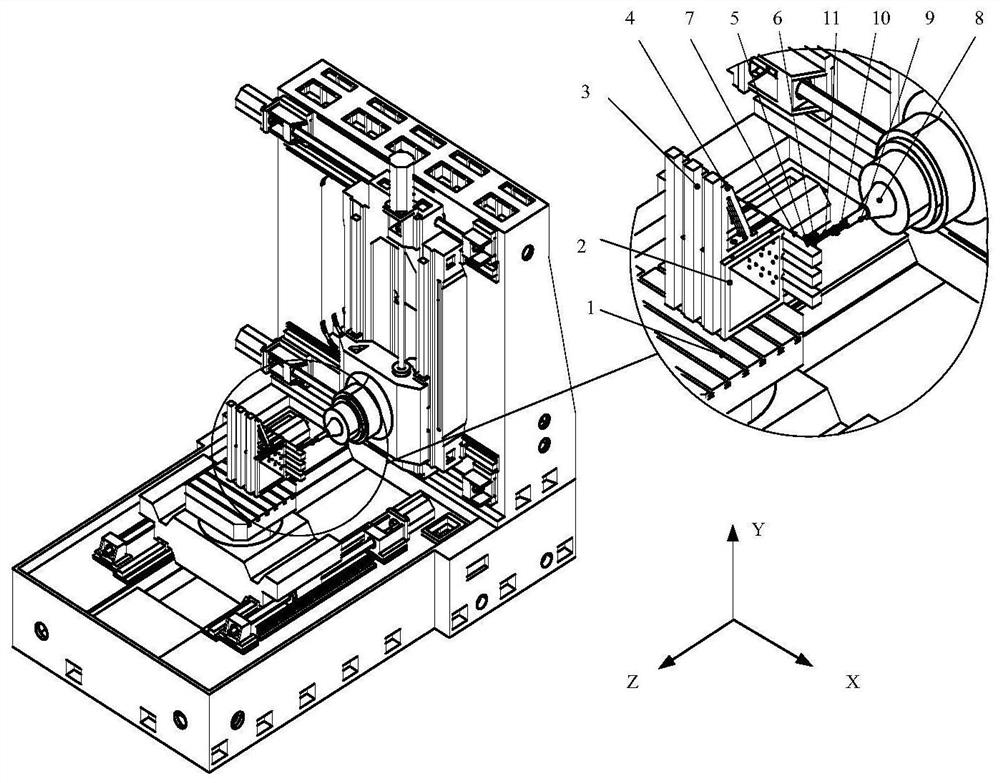

[0051] see Figure 1 to Figure 5 , a thermally induced straightness-perpendicularity error rapid detection device suitable for precision horizontal machining centers, including an eddy current sensor measurement module and a cast iron square box assembly reference module placed on the surface of the workbench, and a cast iron square box assembly reference module It includes a cast iron square box 2 with a processing surface, an L-shaped cast iron support 4, a cast iron ruler 3, 7, and a wedge-shaped tightening block of a linear guide rail.

[0052] The cast iron square box 2 is rigidly connected with the machine tool workbench 1 through T-shaped nuts, double-headed studs, pressing plates, etc.; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com