Method for measuring focus and equivalent f coefficient using optical grating type wave-front curvature sensing unit

A wavefront curvature and sensor technology, applied in the field of efficiency f number, can solve the problems of system instability and high manufacturing process requirements, and achieve the effect of simple calibration and easy optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

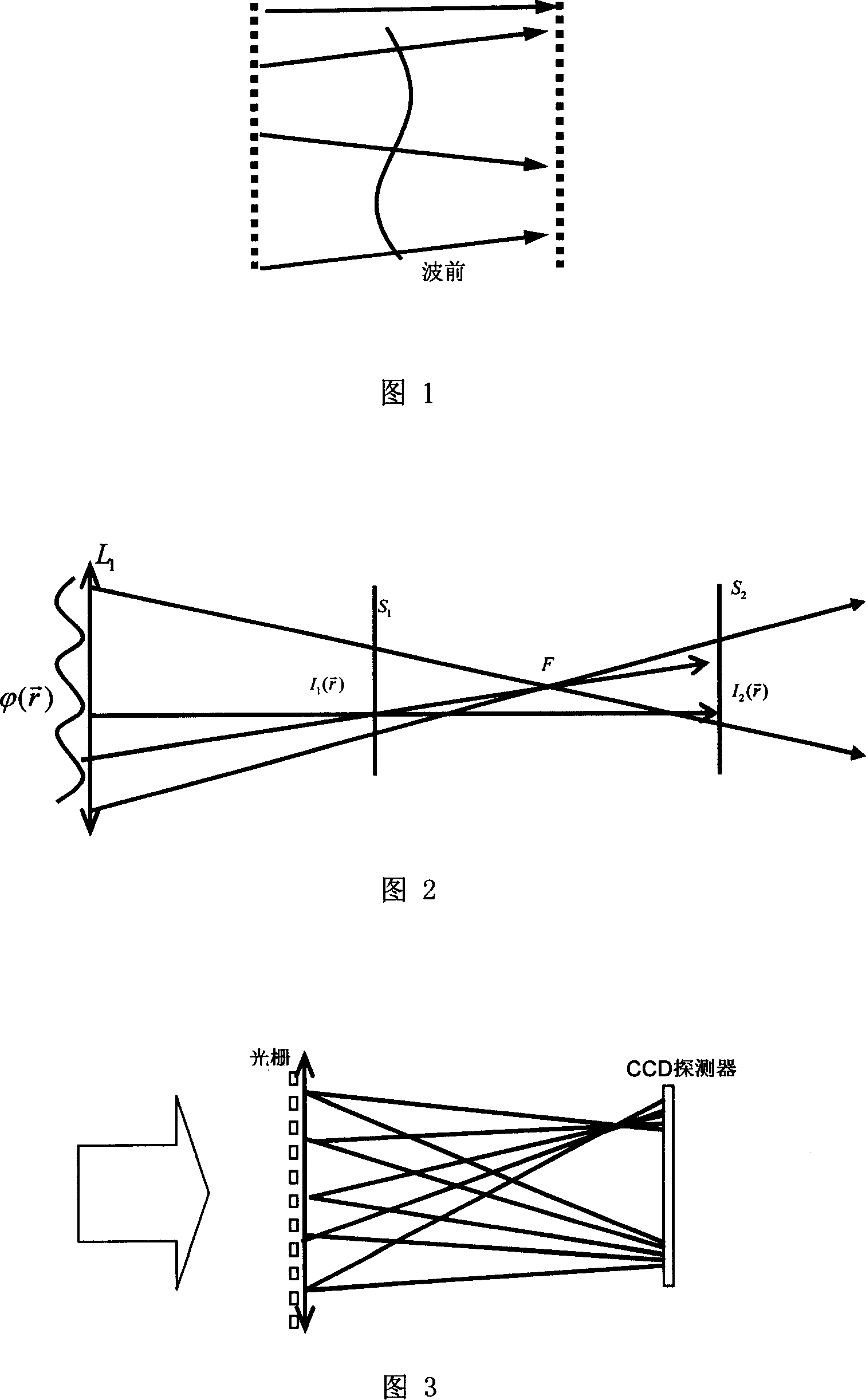

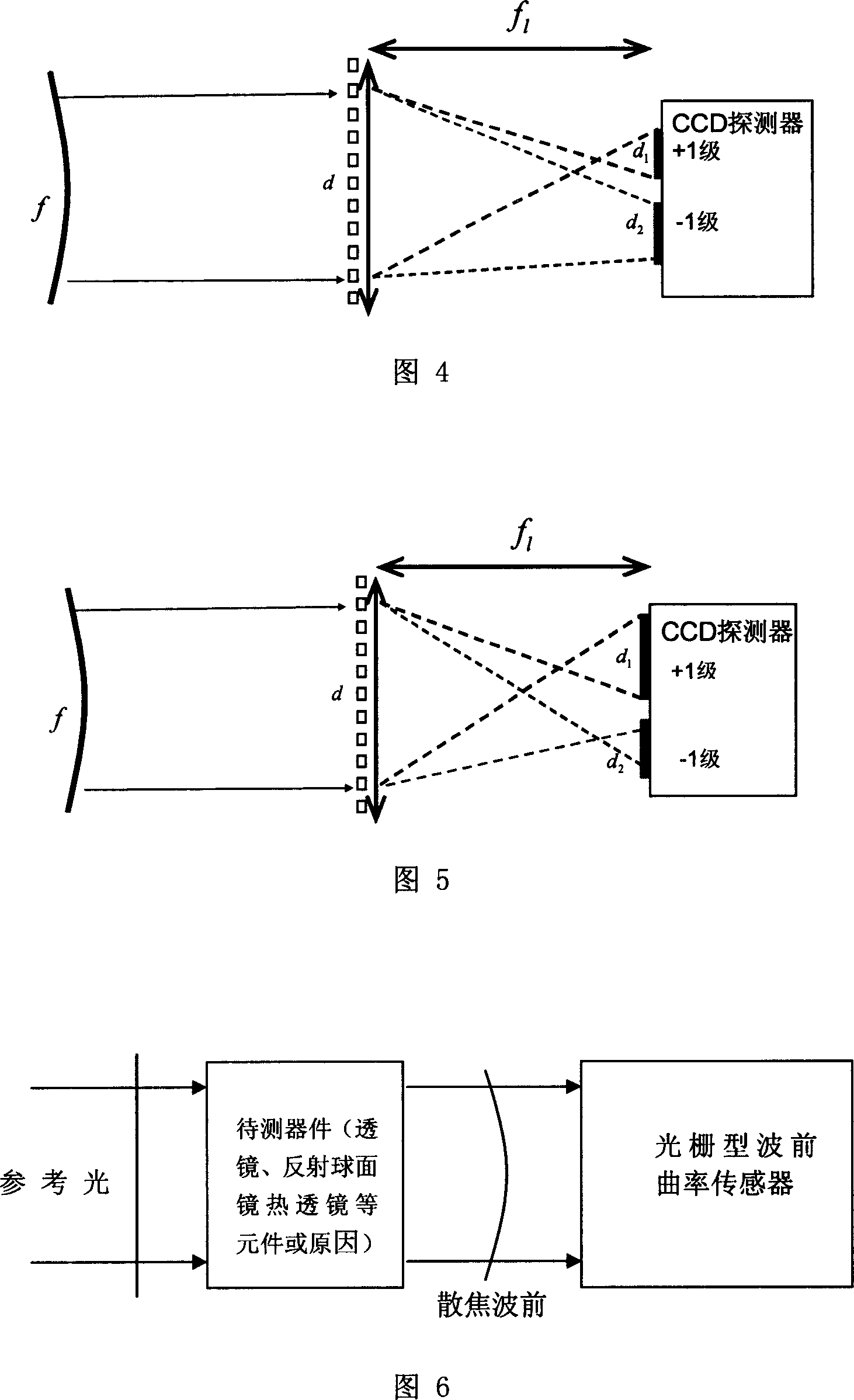

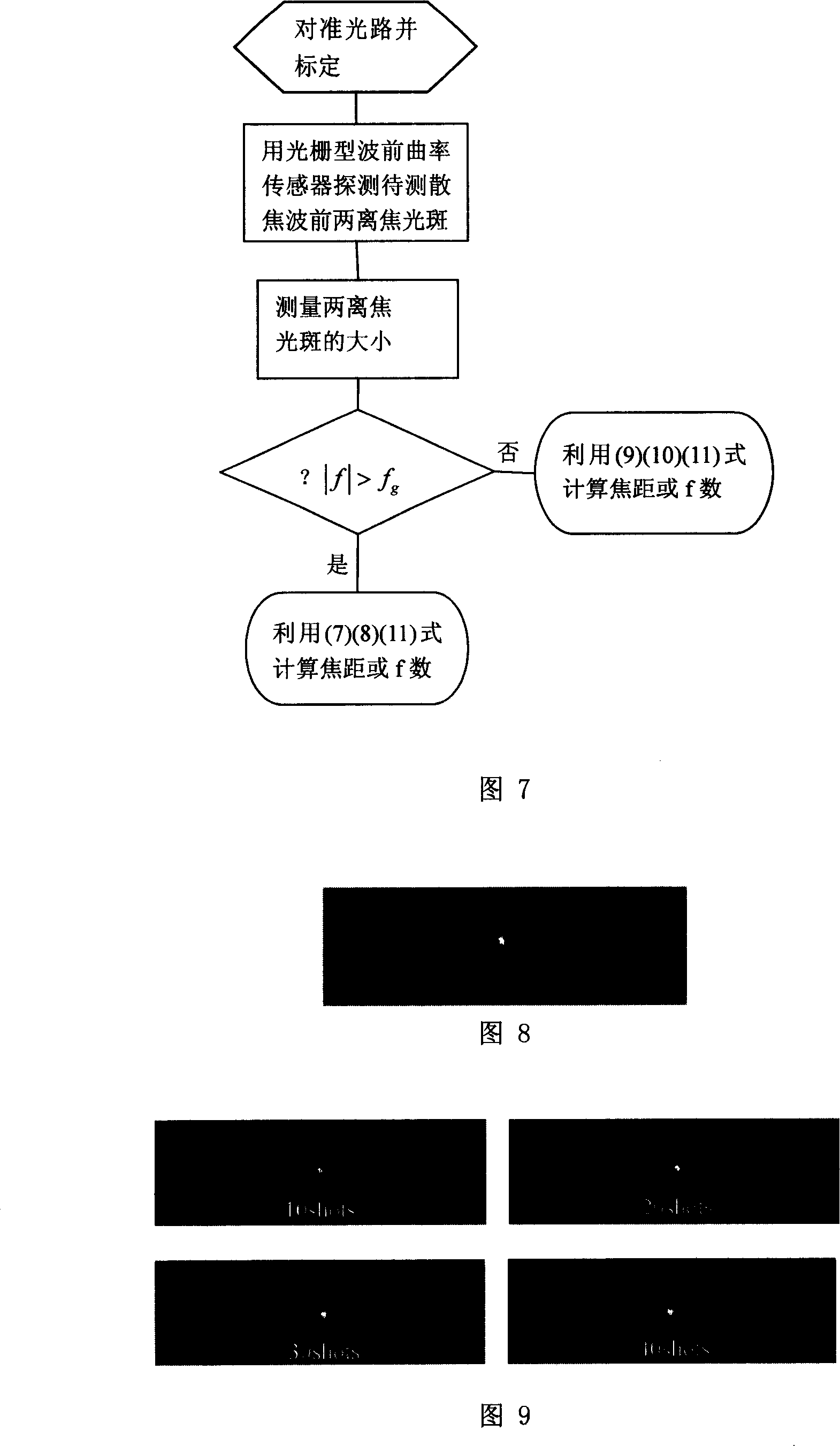

[0038] Lenses, reflective spherical mirrors, thermal lenses, etc., can produce spherical wavefronts with a certain radius of curvature or focal length, that is, fourth-order Zernike polynomial distortion wavefronts - defocused wavefronts. When the incident wavefront is a defocused wavefront, the diameters of the two defocused spots collected by the grating wavefront curvature sensor change. Therefore, the focal length of the incident wavefront, that is, the focal length of the measured lens, reflective spherical mirror, thermal lens, can be determined by simple spot diameter measurement. When the incident wavefront of the grating-type wavefront curvature sensor is a plane wave, the diameter d of the rear defocused spot measured by the grating-type wavefront curvature sensor 1 and the diameter d of the front defocused spot 2 equal. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com