Two-phase opposed super magnetostrictive self-sensing driver

A technology of giant magnetostriction and giant magnetostrictive rod, which is applied to piezoelectric effect/electrostrictive or magnetostrictive motors, valve devices, engine components, etc. It can improve the system response speed and control accuracy, enhance the system reliability, and simplify the system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

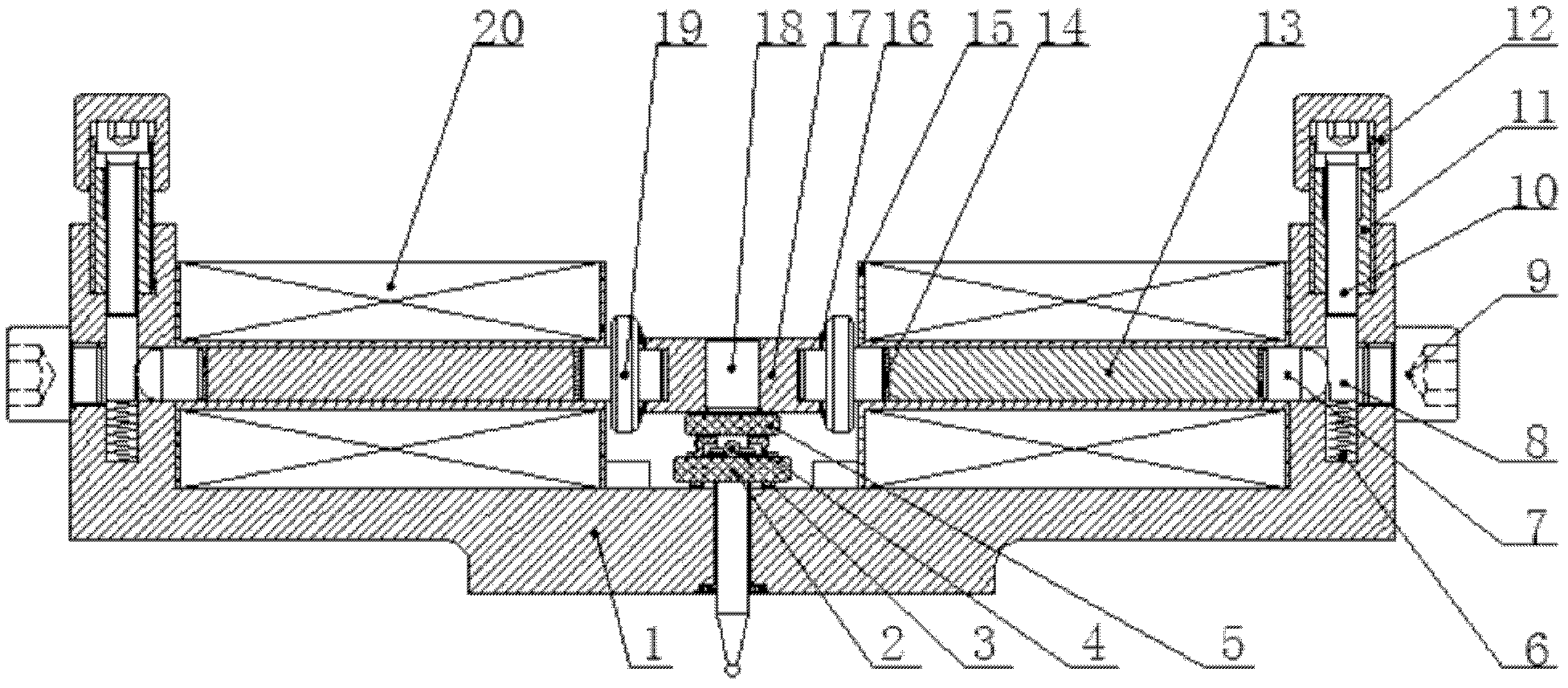

[0023] like Figures 1 to 9The novel structure of the dual-phase opposing giant magnetostrictive self-sensing driver shown in the present invention is mainly composed of a giant magnetostrictive self-sensing driver and a dual-output digital control power supply with self-sensing signal detection and feedback functions. The coupling between two self-sensing drive components with symmetrical structure is used to convert the input current signal into the displacement of the drive rod and the output of the driving force, and the dual-output numerical control power supply with self-sensing signal detection and feedback function is The two drive coils provide a stable differential voltage and a suitable drive current, and feed back the deflected displacement information of the connector 17 to the digital control part of the numerical control power su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com