Double layer printed circuit board capable of implementing impedance control

A printed circuit board, impedance control technology, applied in the direction of printed circuits, printed circuits, printed circuit components, etc., can solve problems such as unreasonable, non-compliance with impedance matching, and failure to consider the requirements of transmission line 150 impedance control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

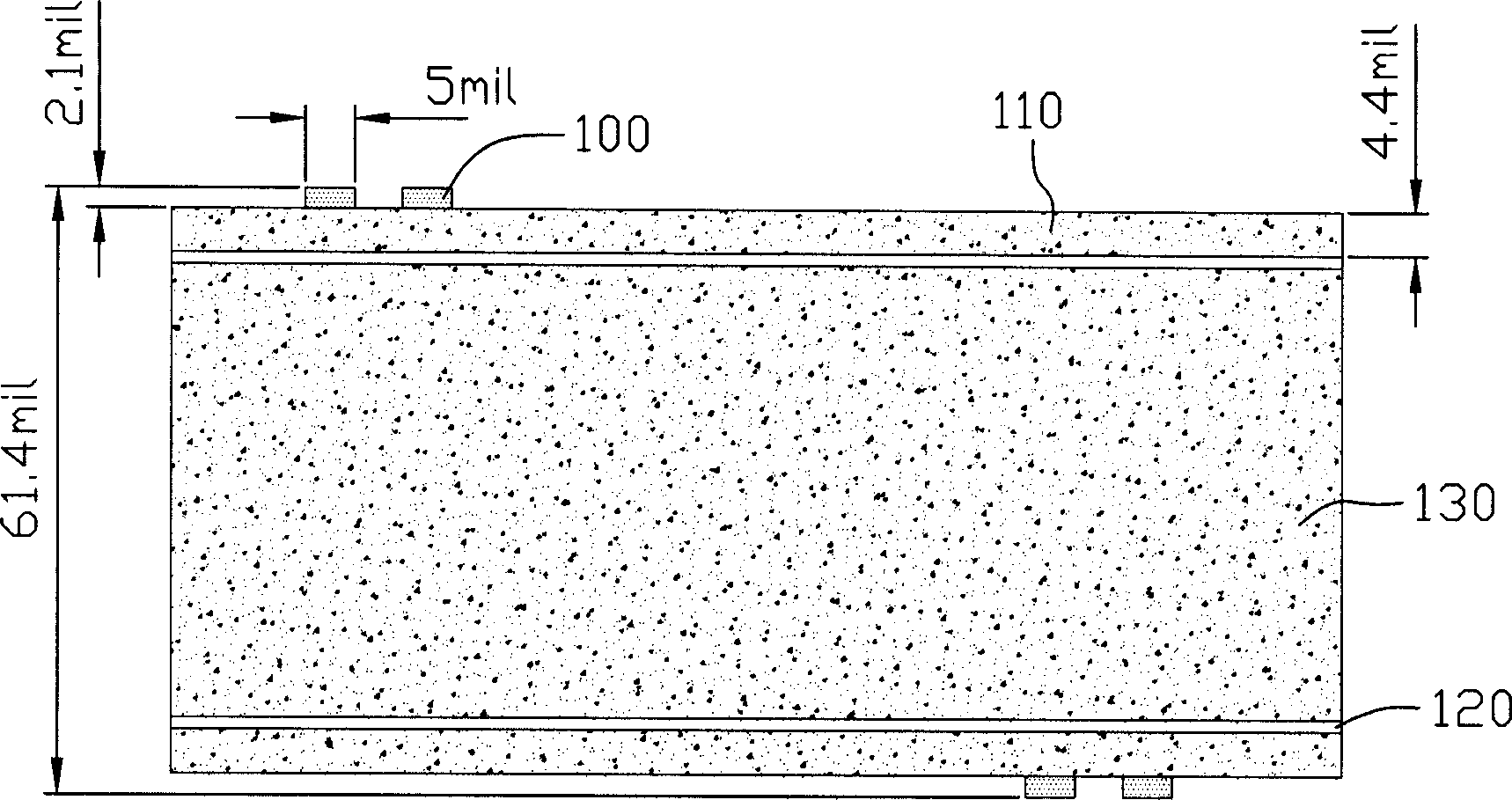

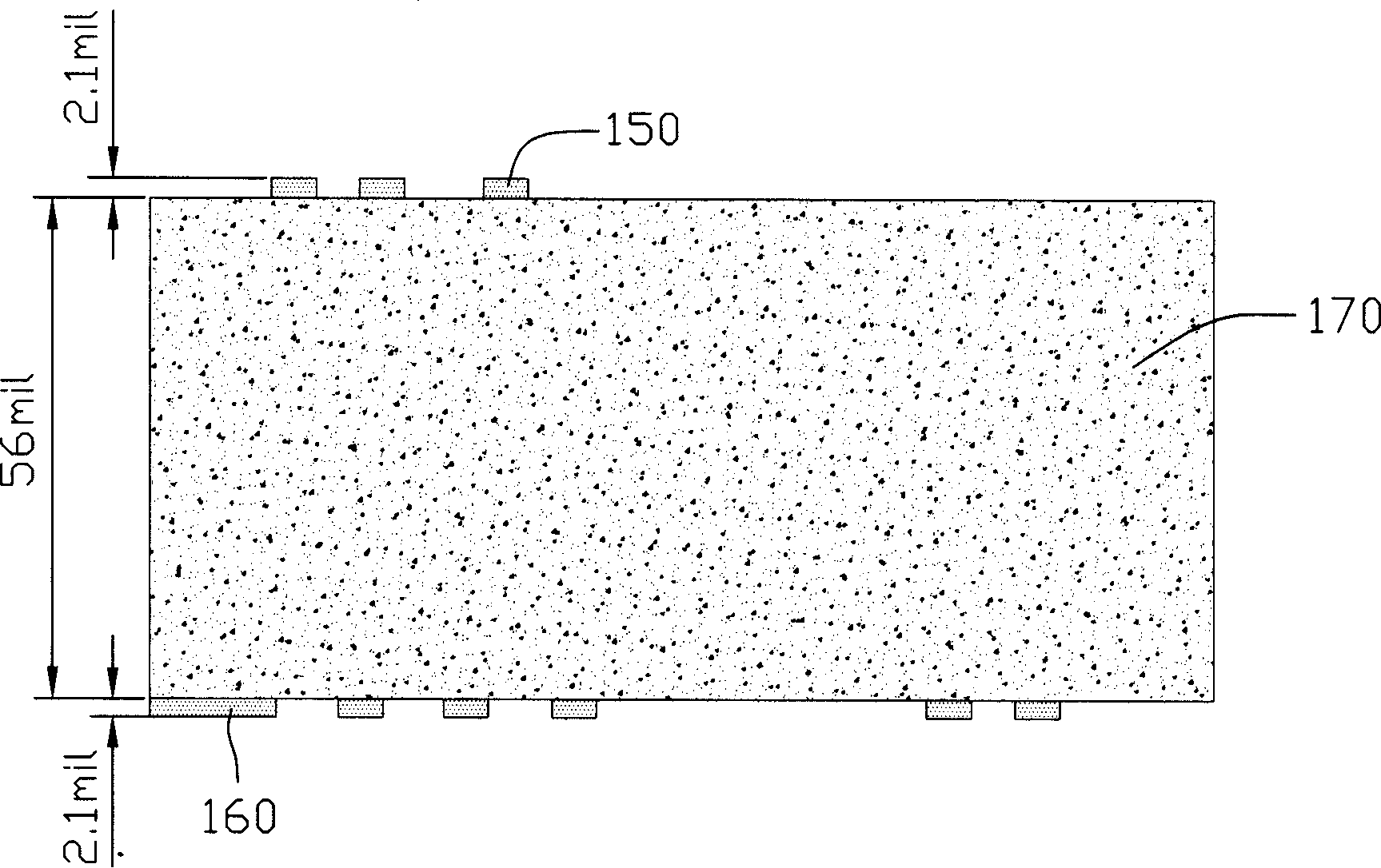

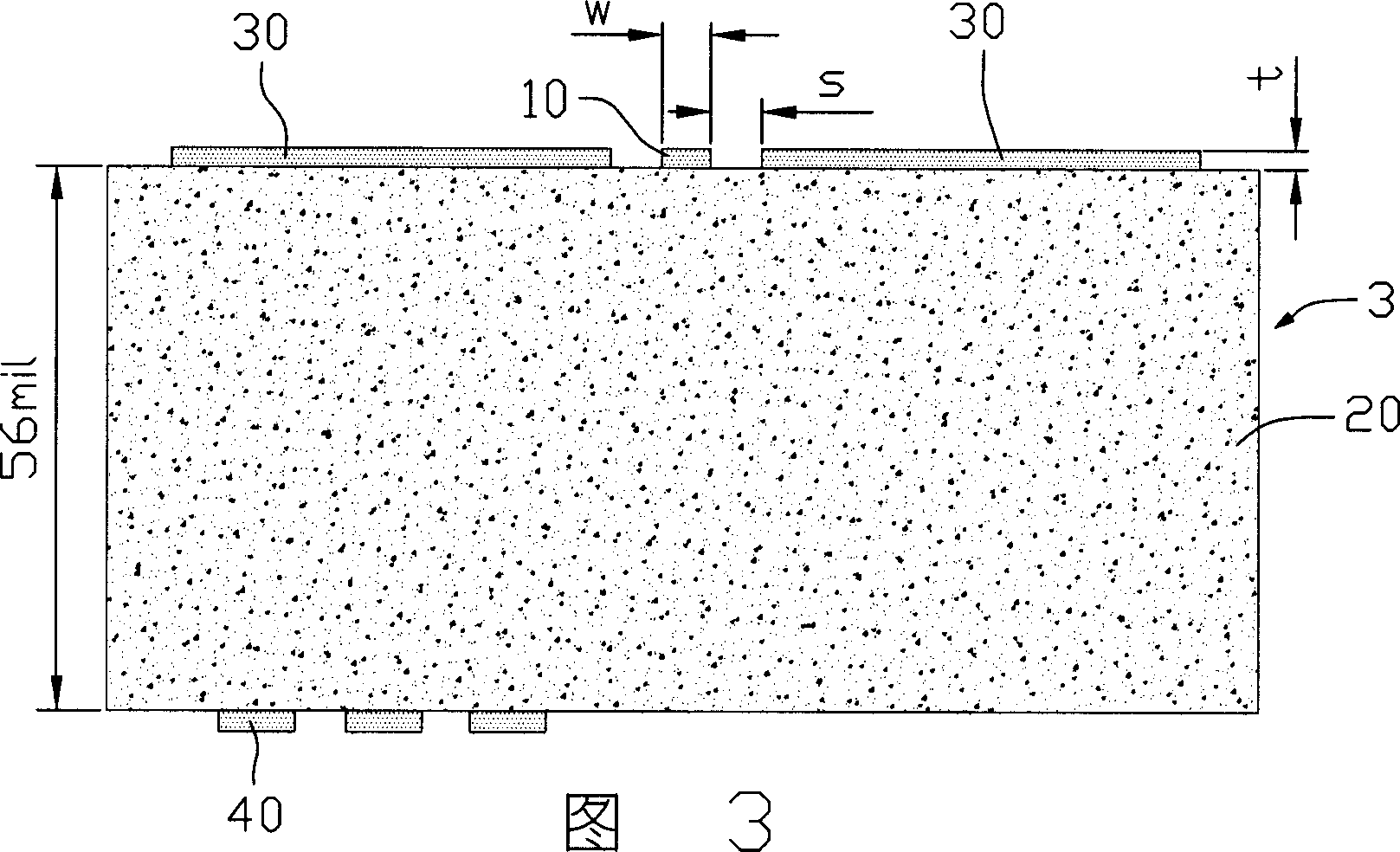

[0014] The present invention can realize the first embodiment of the two-layer printed circuit board of impedance control, as shown in Figure 3, two-layer printed circuit board 3 comprises several high-speed signal transmission lines (this embodiment is single-ended transmission line 10), a layer 20, several ground layers 30 and several low-speed signal lines 40. A grounding layer 30 is arranged on both sides of each single-ended transmission line 10. The grounding layer 30 and the single-ended transmission line 10 are arranged side by side on the dielectric layer 20. The thickness t of the grounding layer 30 is equal to the thickness t of the single-ended transmission line 10. The grounding layer 30 The length of is equal to the length of the single-ended transmission line 10. The width of the single-ended transmission line 10 is w, and the distance between each ground layer 30 and the single-ended transmission line 10 is s. To realize the impedance control of the single-end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com