Micro liquid drop driver based on power-on wetting of medium layer

A technology of micro-droplets and drivers, applied in the direction of electric solid-state devices, instruments, circuits, etc., can solve the problems of complex manufacturing process, low dielectric strength, and high price, and achieve simple manufacturing process, low droplet driving voltage, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The EWOD-based micro-droplet driver proposed according to the present invention will be described in detail with reference to embodiments and drawings as follows:

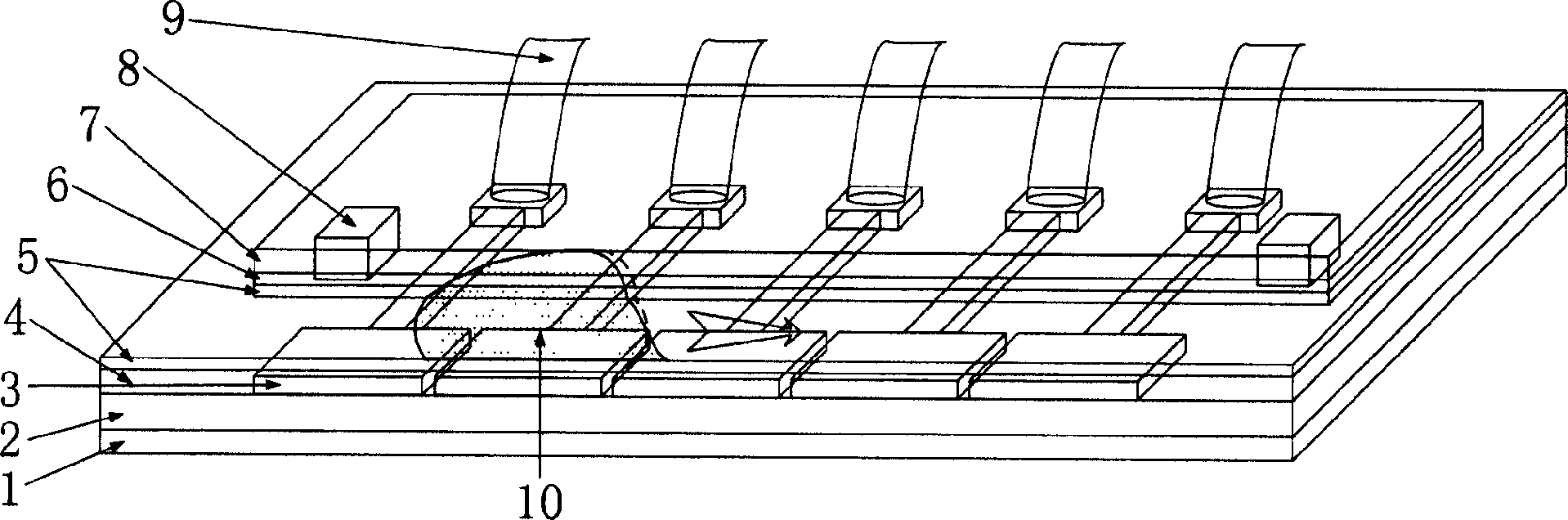

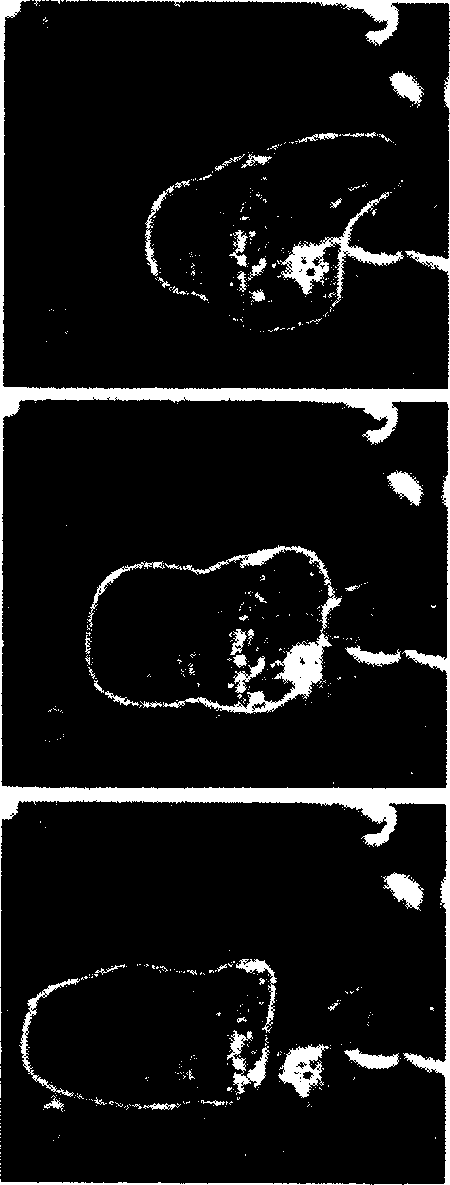

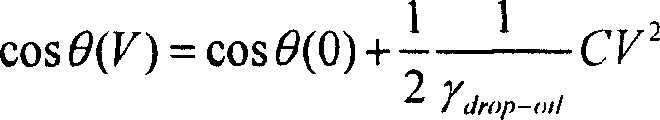

[0016] The structure of the micro-droplet driver based on EWOD is as figure 1 As shown, this embodiment uses Ti and Pt as the bottom electrode, and the bottom electrode array 3 is connected to the external lead 9. Si deposited by LPCVD 3 N 4 The film serves as the dielectric layer. The droplet 10 of deionized water is sandwiched between two plate electrodes, the upper electrode serves as a ground electrode, and the lower electrode is composed of a plurality of independently controllable microelectrode arrays. Each electrode is square, and the distance between the electrodes is 20 μm. An interdigital structure is used between the two electrodes to make it easier for the droplets to move from one electrode to the other. In order to avoid the contact between the liquid and the electrode and obtain good breakdown c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com