Co-doped in-situ MoS2 electrode and a preparation method thereof

A molybdenum disulfide, in-situ electrode technology, applied in chemical instruments and methods, cobalt compounds, inorganic chemistry, etc., can solve the problem of weak conductivity of molybdenum disulfide, affecting electron transport, restricting electrocatalytic chemical reactions and electrode stability, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

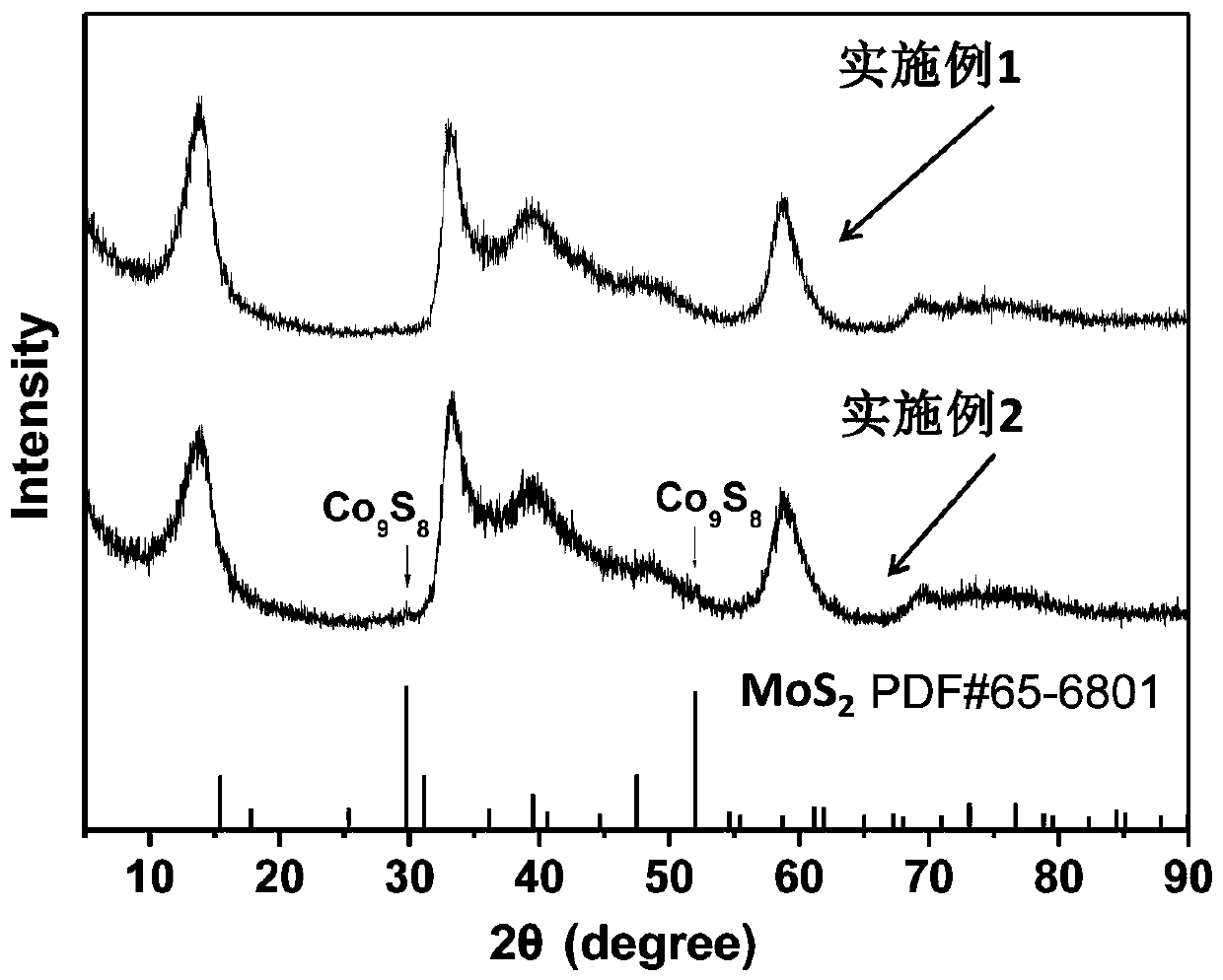

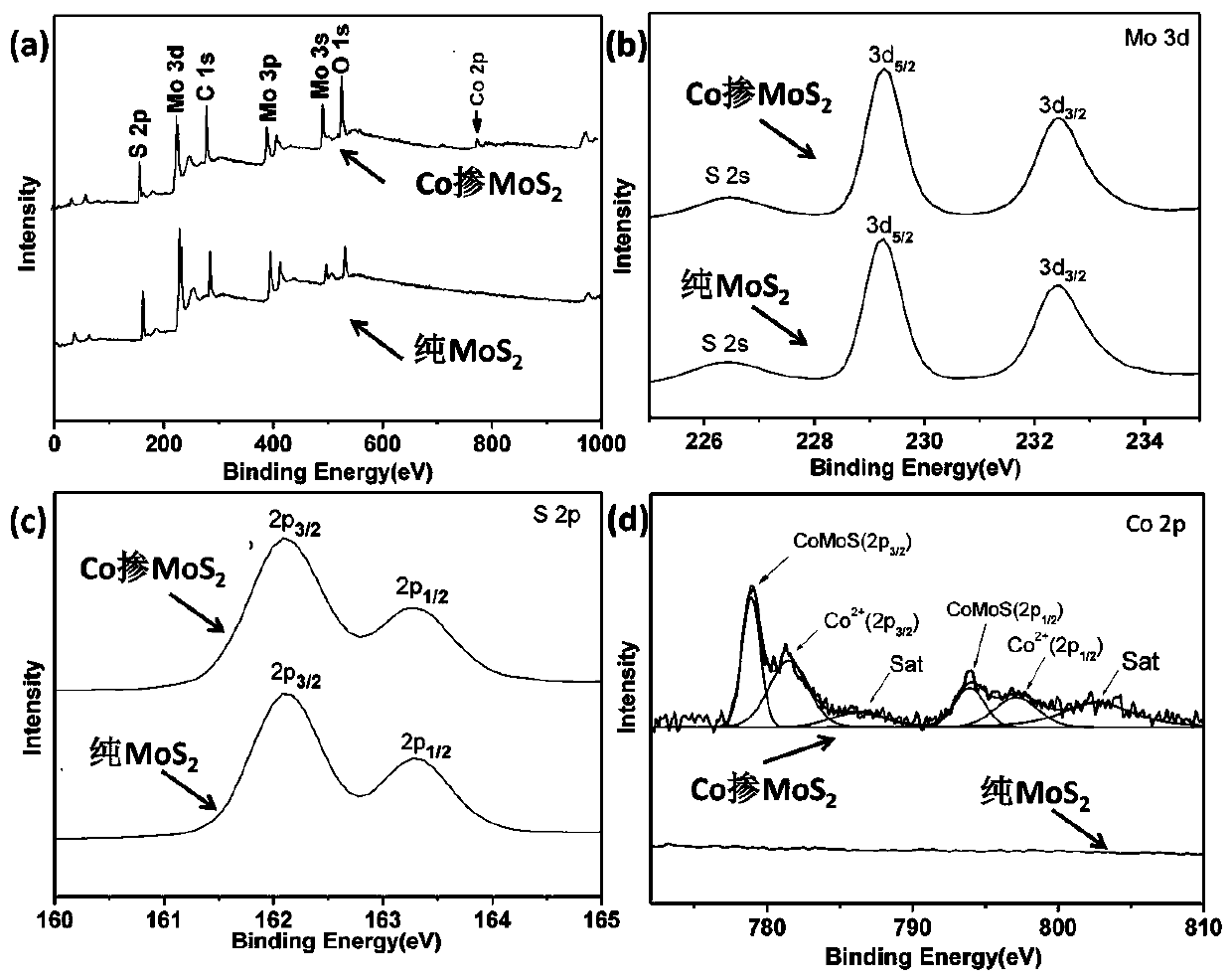

[0026] At room temperature, dissolve 0.9 mmol of molybdenum chloride in 3 mL of ethanol solution, then add 0.1 mmol of cobalt chloride, stir and dissolve the cobalt chloride, add 3 mmol of thiourea, and stir and dissolve the thiourea. Apply 100 μL of the precursor liquid onto a flat 2.5 cm×2.5 cm graphite paper surface, and dry it on a hot stage at 90° C. for 10 min. The substrate coated with Co-Mo-S was placed in a tube furnace for solid-state reaction at 600 °C for 1 h under the protection of Ar. After the furnace temperature cools naturally, take it out. An electrode uniformly loaded with cobalt-doped molybdenum disulfide on graphite paper can be obtained, and the loading capacity is about 270μg / cm 2 . figure 1 The powder XRD of cobalt-doped molybdenum disulfide prepared in Example 1 is shown. It can be seen from the figure that the phase of cobalt-doped molybdenum disulfide is 2H-type molybdenum disulfide, and there are no other impurity phases. It is initially indicated...

Embodiment 2

[0028] At room temperature, dissolve 1.8 mmol of molybdenum chloride in 3 mL of ethanol solution, then add 0.2 mmol of cobalt chloride, stir and dissolve the cobalt chloride, add 4 mmol of thiourea, and stir and dissolve the thiourea. Apply 100 μL of the precursor liquid onto a flat graphite paper surface of 2.5 cm×2.5 cm, and dry it on a hot stage at 70° C. for 20 min. The substrate coated with Co-Mo-S was placed in a tube furnace for solid-state reaction at 600 °C for 1 h under the protection of Ar. After the furnace temperature cools naturally, take it out. An electrode uniformly loaded with cobalt-doped molybdenum disulfide on graphite paper can be obtained, and the loading capacity is about 540 μg / cm 2 . figure 1 The powder XRD of cobalt-doped molybdenum disulfide prepared in Example 2 is shown. It can be seen from the figure that most of the phases of cobalt-doped molybdenum disulfide are 2H type molybdenum disulfide, but there is a small amount of Co 9 S 8 .

Embodiment 3

[0030] At room temperature, dissolve 0.9 mmol of molybdenum chloride in 3 mL of ethanol solution, then add 0.1 mmol of cobalt chloride, stir and dissolve the cobalt chloride, add 3 mmol of thiourea, and stir and dissolve the thiourea. 100 μL of the precursor solution was dropped onto a flat surface of 2.5 cm×2.5 cm graphite paper, and dried on a hot stage at 80° C. for 15 min. The substrate coated with Co-Mo-S was placed in a tube furnace for solid-state reaction at 800 °C for 30 min under the protection of Ar. After the furnace temperature cools naturally, take it out. An electrode uniformly loaded with cobalt-doped molybdenum disulfide on graphite paper can be obtained, and the loading capacity is about 270μg / cm 2 . Figure 5The powder SEM-EDS of cobalt-doped molybdenum disulfide prepared in Example 3 is shown. It can be seen from the figure that cobalt element is easy to concentrate on the surface of the sample at a high temperature of 800°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com