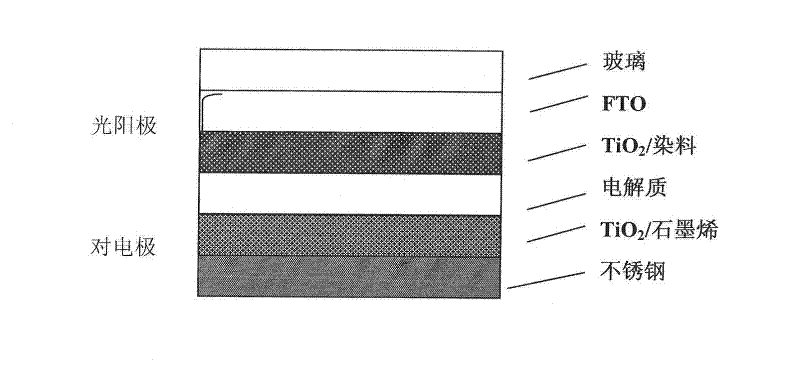

Graphene composite porous counter electrode, preparation method and application thereof

A graphene composite and graphene technology, applied in circuits, capacitors, photosensitive equipment, etc., can solve the problems of expensive raw materials, lower surface energy, and insufficient pores, and achieve simple and effective preparation methods, reduce current loss, and reduce energy loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

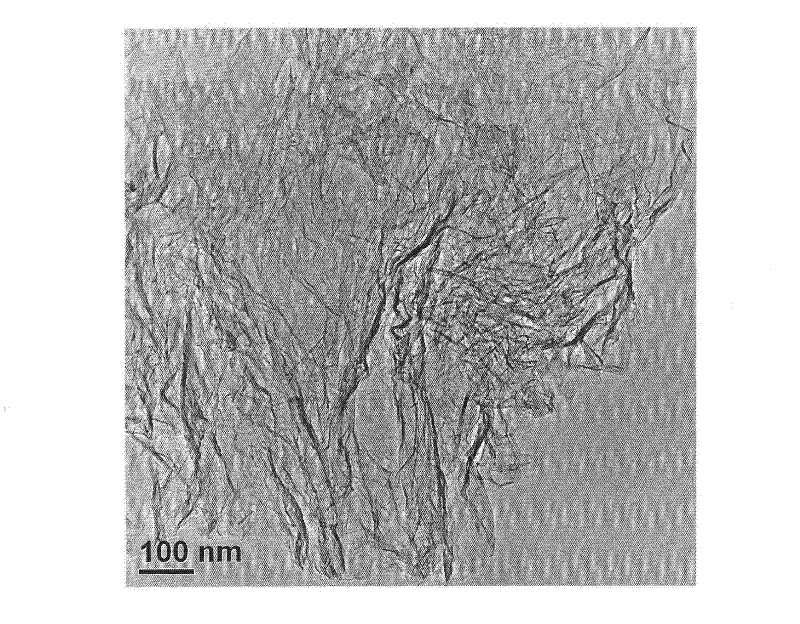

[0033] Add 1g graphite to 100mL concentrated sulfuric acid, add 4.5g KMnO 4 and 0.6g NaNO3 , mix well, react at room temperature for 5 days, add deionized water, after reacting for 2 hours, add H 2 o 2 , reducing unreacted potassium permanganate, the resulting brown product, washed with HCl, washed with water, and dried to obtain graphene oxide; dissolve 0.1g of the above graphene oxide in 100mL of water, add 0.5g of triton, ultrasonic 30min , add 0.2mL hydrazine hydrate dropwise, react at 100°C for 24h, wash with deionized water, and obtain graphene, figure 2 Its TEM photo; 0.1g of the above graphene powder and 0.025g of SnO 2 Mix the nano-powders, add 2mL ethanol and 0.05g ethyl cellulose, and ball mill for 16h. 2 Heat treatment at 450 °C for 3 h in a mixed gas to prepare a graphene / titanium oxide composite counter electrode. The photoelectric conversion efficiency of the dye-sensitized solar cell prepared by using the graphene / titanium oxide composite counter electrode...

Embodiment 2

[0035] Add 1g graphite to 100mL concentrated sulfuric acid, add 4.5g KMnO 4 and 0.6g NaNO 3 , mix well, react at room temperature for 5 days, add deionized water, after reacting for 2 hours, add H 2 o 2 , reducing unreacted potassium permanganate, the resulting brown product, washed with HCl, washed with water, and dried to obtain graphene oxide; dissolve 0.1g of the above graphene oxide in 100mL of water, add 0.5g of triton, ultrasonic 30min , add 0.2mL of hydrazine hydrate dropwise, react at 100°C for 24h, wash with deionized water to obtain graphene; mix 0.1g of the above graphene powder with 0.025g of P25 nanopowder, add 2mL of terpineol and 0.05g of ethyl cellulose, After ball milling for 16 hours, the resulting composite slurry was coated on the conductive glass by scraping, and the Ar / H 2 Heat treatment at 500 °C for 2 h in a mixed gas to prepare a graphene / titanium oxide composite counter electrode. The photoelectric conversion efficiency of the dye-sensitized sola...

Embodiment 3

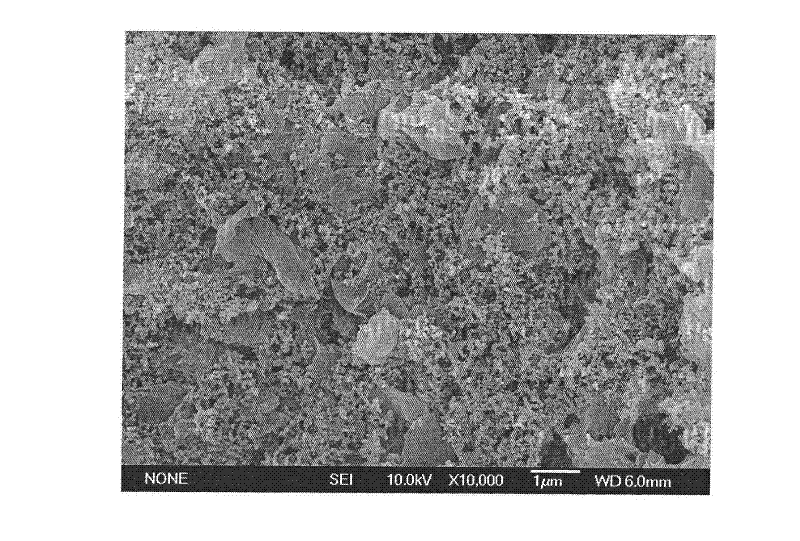

[0037] Add 1g graphite to 100mL concentrated sulfuric acid, add 4.5g KMnO 4 and 0.6g NaNO 3 , mix well, react at room temperature for 5 days, add deionized water, after reacting for 2 hours, add H 2 o 2 , reducing unreacted potassium permanganate, the resulting brown product, washed with HCl, washed with water, and dried to obtain graphene oxide; dissolve 0.1g of the above graphene oxide in 100mL of water, add 0.5g of triton, ultrasonic 30min , add 0.2mL hydrazine hydrate dropwise, react at 100°C for 24h, wash with deionized water to obtain graphene; mix 0.1g of the above graphene powder with 0.025g of P25 titanium oxide nanopowder, add 2mL of terpineol and 0.05g of ethyl cellulose element, ball milled for 16h, and the resulting composite slurry was coated on a stainless steel sheet by scraping or screen printing. 2 Heat treatment at 500°C for 2h in mixed gas. image 3 It is the SEM photo of the graphene / titanium oxide composite counter electrode prepared above. It can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Short circuit current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com