Silicon-based coplanar micro-gas sensor chip and its application in micro-gas sensor preparation

A gas sensor and coplanar technology, applied in piezoelectric devices/electrostrictive devices, instruments, scientific instruments, etc., can solve the problems of poor sensor reliability and achieve high reliability, low production cost, and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

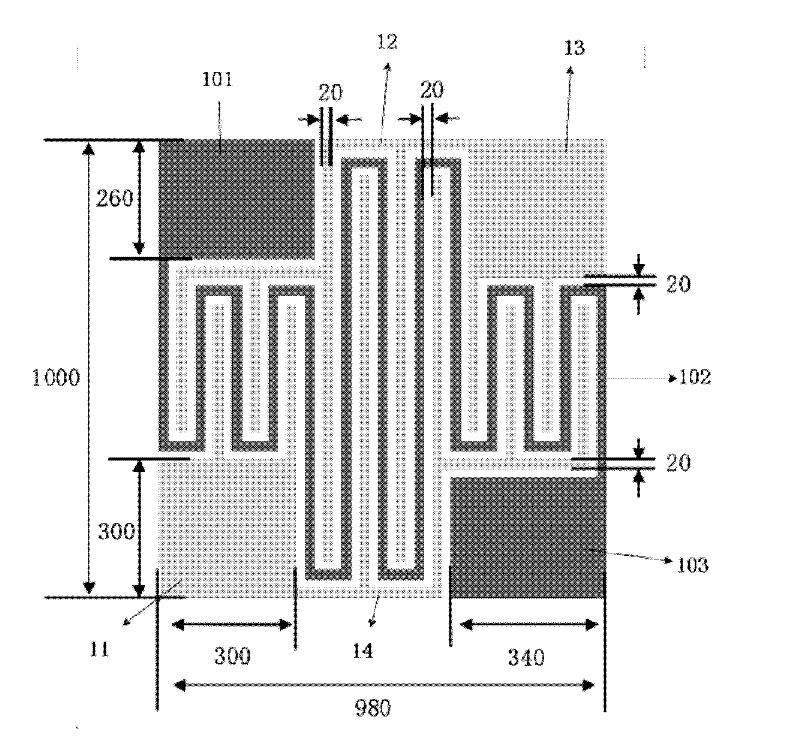

Embodiment 1

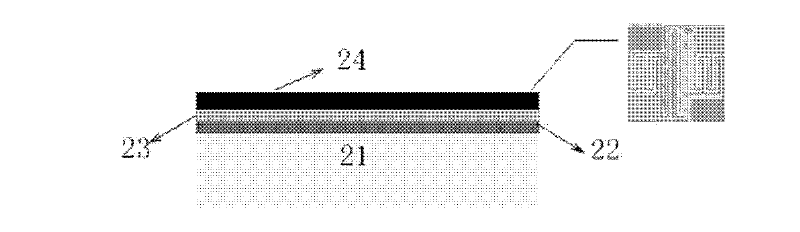

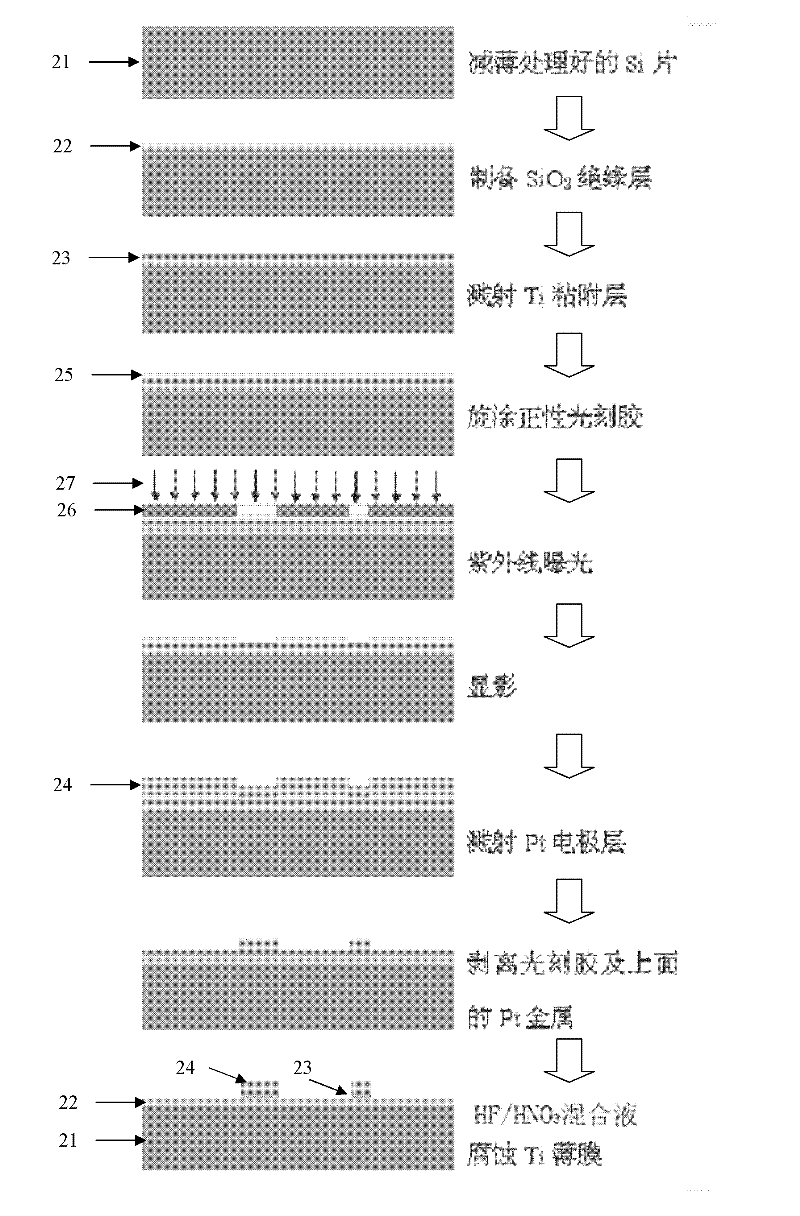

[0036] 1. Select the crystal orientation Si wafer, and reduce it as thin as possible under the condition of meeting the mechanical strength requirements of scribing. In this example, it is thinned to 300 μm; on one side of the thinned Si wafer Preparation of 300nm Thick SiO by Mixed Oxidation Method 2 Insulation layer; using semiconductor processing technology, in SiO 2 Sputter a 45nm-thick Ti adhesion layer on the insulating layer; spin-coat photoresist BP212 on the side of the Si wafer where metal Ti has been sputtered by using a homogenizer, the speed of the homogenizer is 3000r / min, and the homogenization time is 25s; After gluing, cover the glass mask on the Si wafer and align it, and expose it under 1000W optical power for 4s; use a positive photoresist developer to develop; sputter 250nm thick metal Pt on the photoresist-coated side of the developed Si wafer; Use the stripping process to strip the photoresist and the metal Pt on it; use HF:HNO 3 (molar ratio 4:1) the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com