Method for efficiently removing nitrate from underground water through Ti-graphene electrode

A graphene electrode, nitrate technology, applied in the treatment of polluted groundwater/leachate, chemical instruments and methods, water pollutants, etc. problem, to achieve the effect of easy control, simple production process, and improved electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

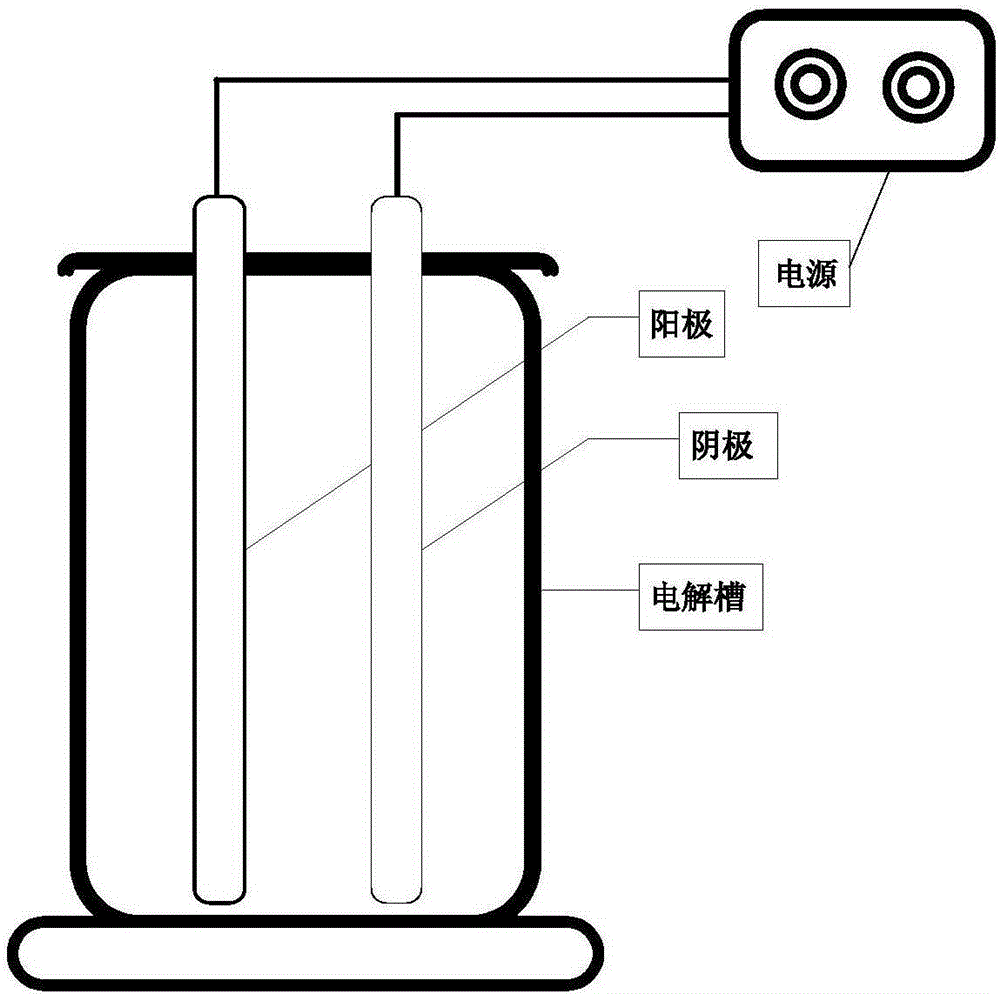

[0041] Such as figure 1 As shown, the electrolytic tank is a cylindrical water tank, made of polyethylene material, and a DC voltage stabilizer is used as a power source. The effective voltage is 0-100V and the effective current is 0-5A.

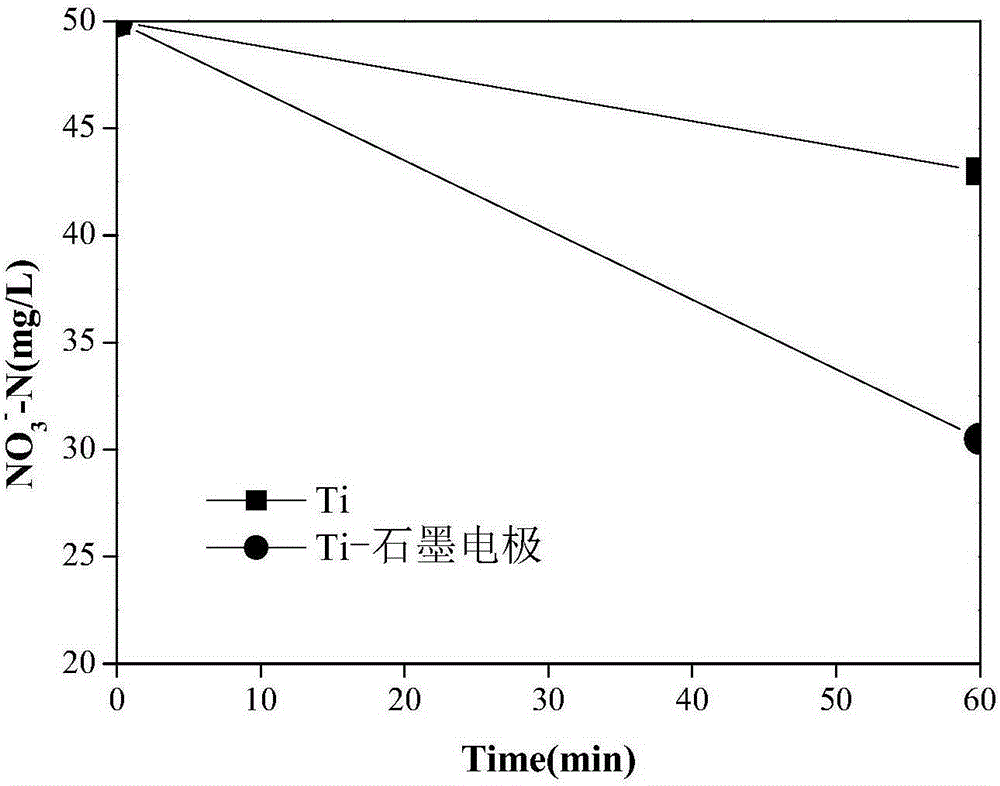

[0042] In the experiment, synthetic nitrate polluted water (NO 3 - -N, 50mg / L; Na 2 SO 4 , 0.5g / L) 150mL into the electrolytic cell, turn on the power supply, adjust the current to make the current 0.75A. The size of the cathode and anode plates are both 10×2.5cm, and the effective area of the plates is 20.0cm 2 , The anode uses Ti / Pt electrode, ①The cathode used is Ti electrode, then the nitrate nitrogen concentration will be reduced from 50.0mg / L to 43.0mg / L after 60 minutes of reaction; ②Ti- made with graphene oxide as auxiliary The graphene electrode is a cathode. The immersion time in the graphene oxide solution is 5 minutes during the production process. After 60 minutes of reaction, the nitrate nitrogen concentration will drop from 50.0...

Embodiment 2

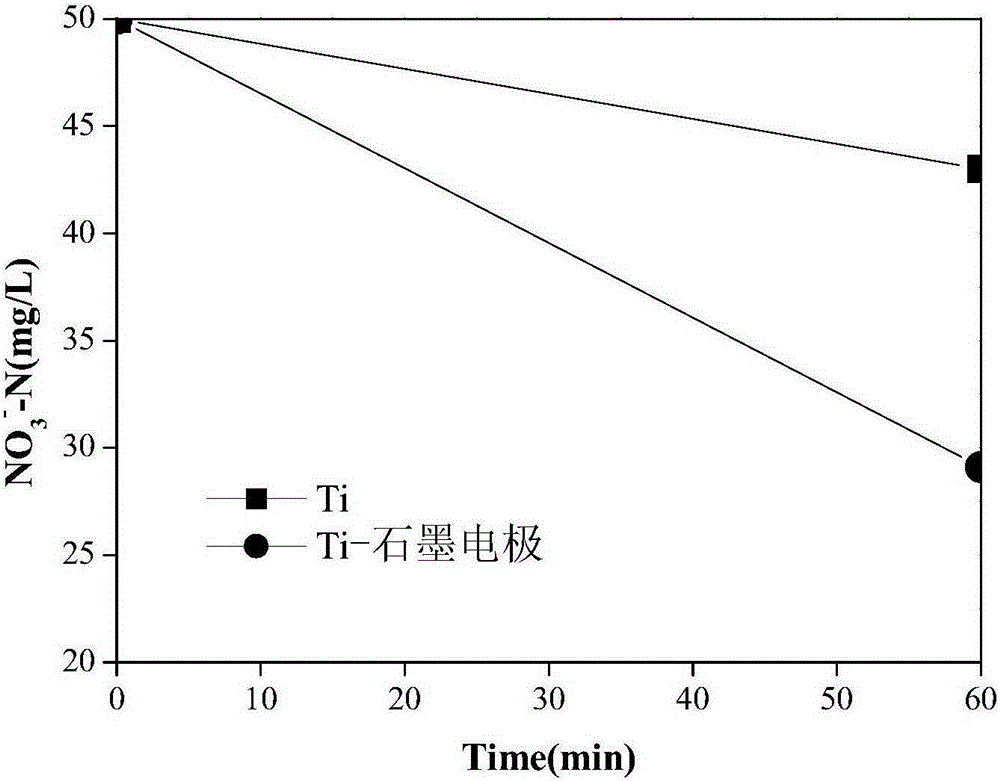

[0044] The electrolytic cell used in the experiment and the method of using nanoelectrodes to remove nitrate are as in Example 1, except that the Ti-graphene electrode used is soaked in the graphene oxide solution for 10 minutes during the manufacturing process. In the experiment, 150mL of nitrate sewage was taken, of which NO 3 - -N, 50mg / L; Na 2 SO 4 , 0.5g / L, the size of the cathode and anode plate is 10.0×2.5cm, and the effective area of the plate is 20cm 2 Under the condition of current intensity of 0.75A, ①The cathode used is a Ti electrode, and the concentration of nitrate nitrogen drops from 50.0mg / L to 44mg / L after 60 minutes of reaction; ②Ti- made with graphene oxide as an aid is used. The graphene electrode is the cathode, and the nitrate nitrogen concentration drops from 50.0mg / L to 29.1mg / L after 60 minutes of reaction. The removal rate is 240% higher than that of the Ti electrode. The result is as follows image 3 Shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com