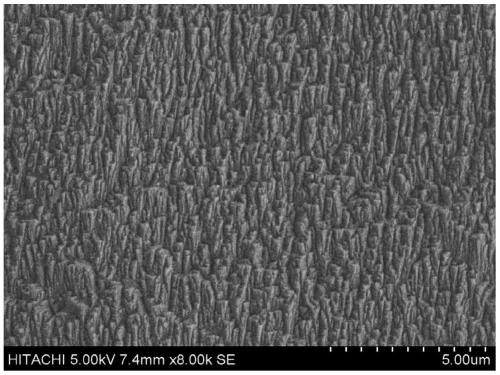

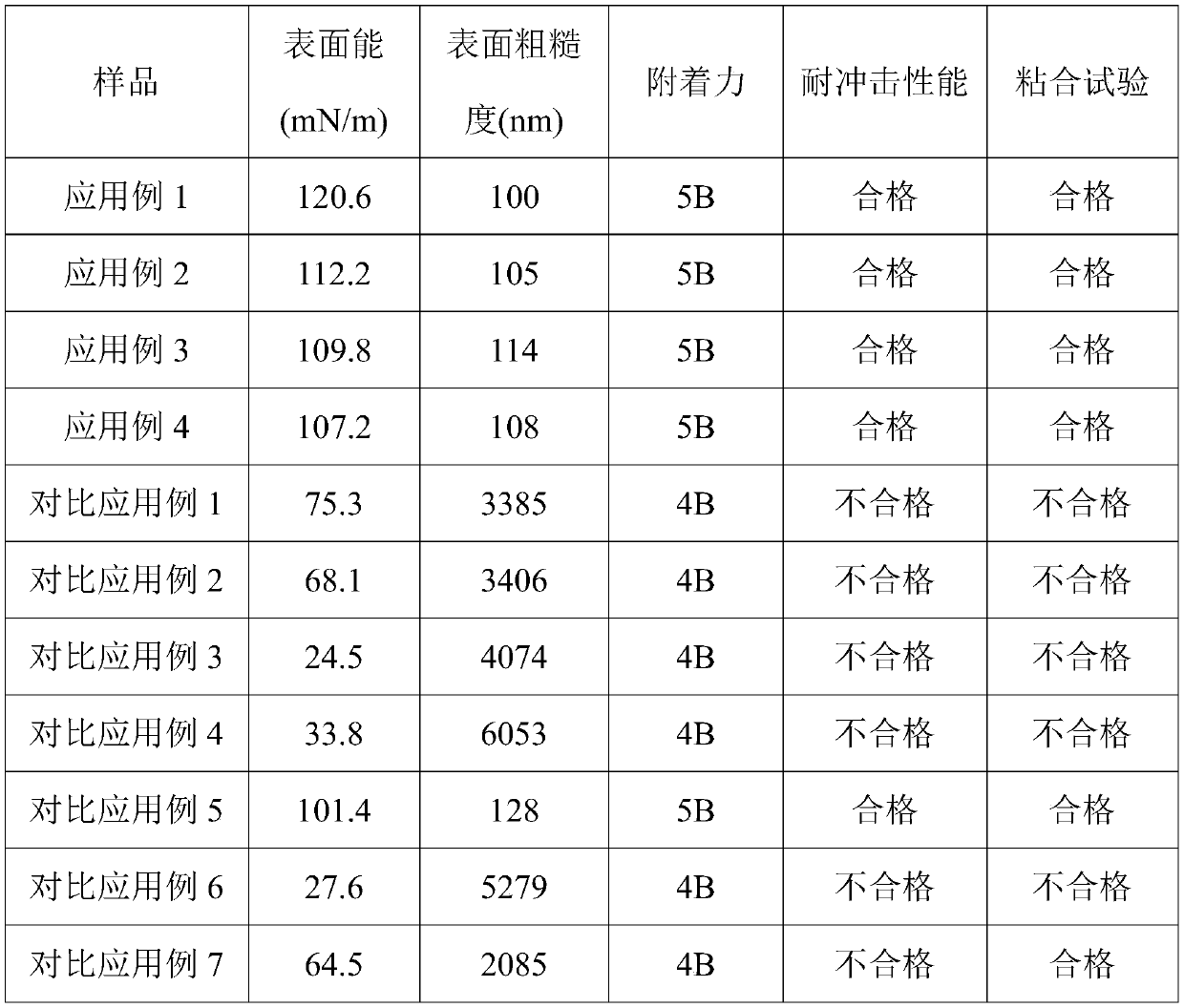

Neutral metal surface coarsening treatment solution with super-hydrophilicity and super-oleophilicity, and preparation method and application thereof

A neutral metal and surface roughening technology, which is applied in the field of neutral metal surface roughening treatment liquid and its preparation, can solve the problems of not necessarily meeting the coating adhesion requirements, meeting the requirements is unknown, and insufficient adhesion, etc. , to achieve the effect of improving surface energy value and adhesion, high metal surface adhesion, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076]This embodiment provides a super-amphiphilic neutral metal surface roughening treatment solution, the super-amphiphilic neutral metal surface roughening treatment solution is based on its total mass of 100%, including the following components: Lanification component A 10 %, haze component B 28% and haze component C 62%;

[0077] The dehydration component A includes alkylsiloxane-modified nano silicon dioxide solution and 1-(3-propanesulfonyl)-2-pyrrolidone bisulfate; the dehydration component B includes C14 fatty acid and The hydroalcoholic liquid of C16 fatty acid and 1-(3-propanesulfonyl)-2-pyrrolidone p-toluenesulfonate; Based on the total mass of the metal surface roughening treatment liquid as 100%, the haze component C Including N, N-dimethyl-N-(2-hydroxyethyl) 2-hydroxyhexadecyl quaternary ammonium phosphate (lane accelerator) 2%, DL-sodium malate (lane dispersant) 3 %, polyethylene glycol diglycidyl ether (penetrating agent) 5%, disodium edetate (water softener)...

Embodiment 2

[0088] This embodiment provides a super-amphiphilic neutral metal surface roughening treatment solution, the super-amphiphilic neutral metal surface roughening treatment solution is based on its total mass of 100%, including the following components: Lanification component A 10 %, haze component B18% and haze component C 72%;

[0089] The dehydration component A includes alkylsiloxane-modified nano-silica solution and 1-(3-propanesulfonyl)-2-pyrrolidone trifluoroacetate; the dehydration component B includes C16 Hydroalcoholic liquid of fatty acid and 1-(3-propanesulfonyl)-2-pyrrolidone trifluoromethanesulfonate; based on the total mass of the metal surface roughening treatment liquid as 100%, the haze component C Including N,N-Dimethyl-N-(2-hydroxyethyl) 2-hydroxyhexadecyl quaternary ammonium phosphate (lane accelerator) 5%, dextran sodium sulfate (lane dispersant) 5% %, ethylene glycol diglycidyl ether (penetrating agent) 10%, disodium edetate (water softener) 5%, 1-hydroxyb...

Embodiment 3

[0100] This embodiment provides a super-amphiphilic neutral metal surface roughening treatment liquid, the super-amphiphilic neutral metal surface roughening treatment liquid includes the following components based on its total mass of 100%: Lanification component A 5 %, haze component B 30% and haze component C 65%;

[0101] The dehydration component A includes alkylsiloxane-modified nano-silica solution and 1-(3-propanesulfonyl)-2-pyrrolidone trifluoroacetate; the dehydration component B includes C16 Hydroalcoholic liquid of fatty acid and 1-(3-propanesulfonyl)-2-pyrrolidone p-toluenesulfonate; based on the total mass of the metal surface roughening treatment liquid as 100%, the haze component C includes N,N-Dimethyl-N-(2-hydroxyethyl) cetyl quaternary ammonium phosphate (lane accelerator) 4%, sodium lauryl sulfate (lane dispersant) 8%, butylene glycol Diglycidyl ether (penetrating agent) 5%, trisodium nitrilotriacetate (water softener) 10%, methyl benzotriazole (metal corr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com