Processing method for enhancing lamination bonding force of rigid and flexible boards

A technology of soft and hard boards and processing methods, which is applied in the direction of assembling printed circuits with electrical components, which can solve problems such as delamination, failure to solve delamination problems, insufficient bonding force between soft boards and hard boards, etc., and achieve enhanced lamination The effect of bonding force and avoiding delamination of soft and hard boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

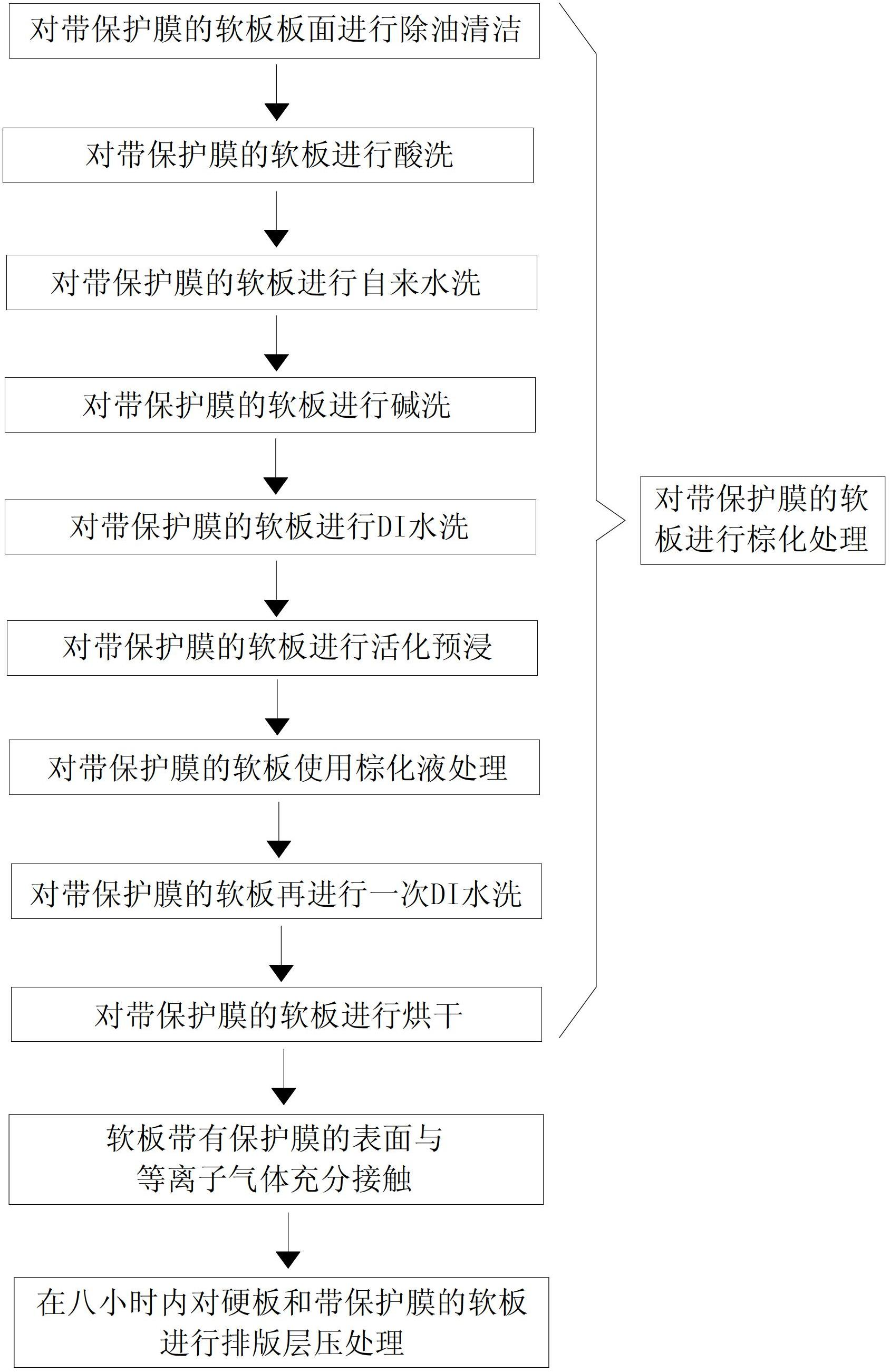

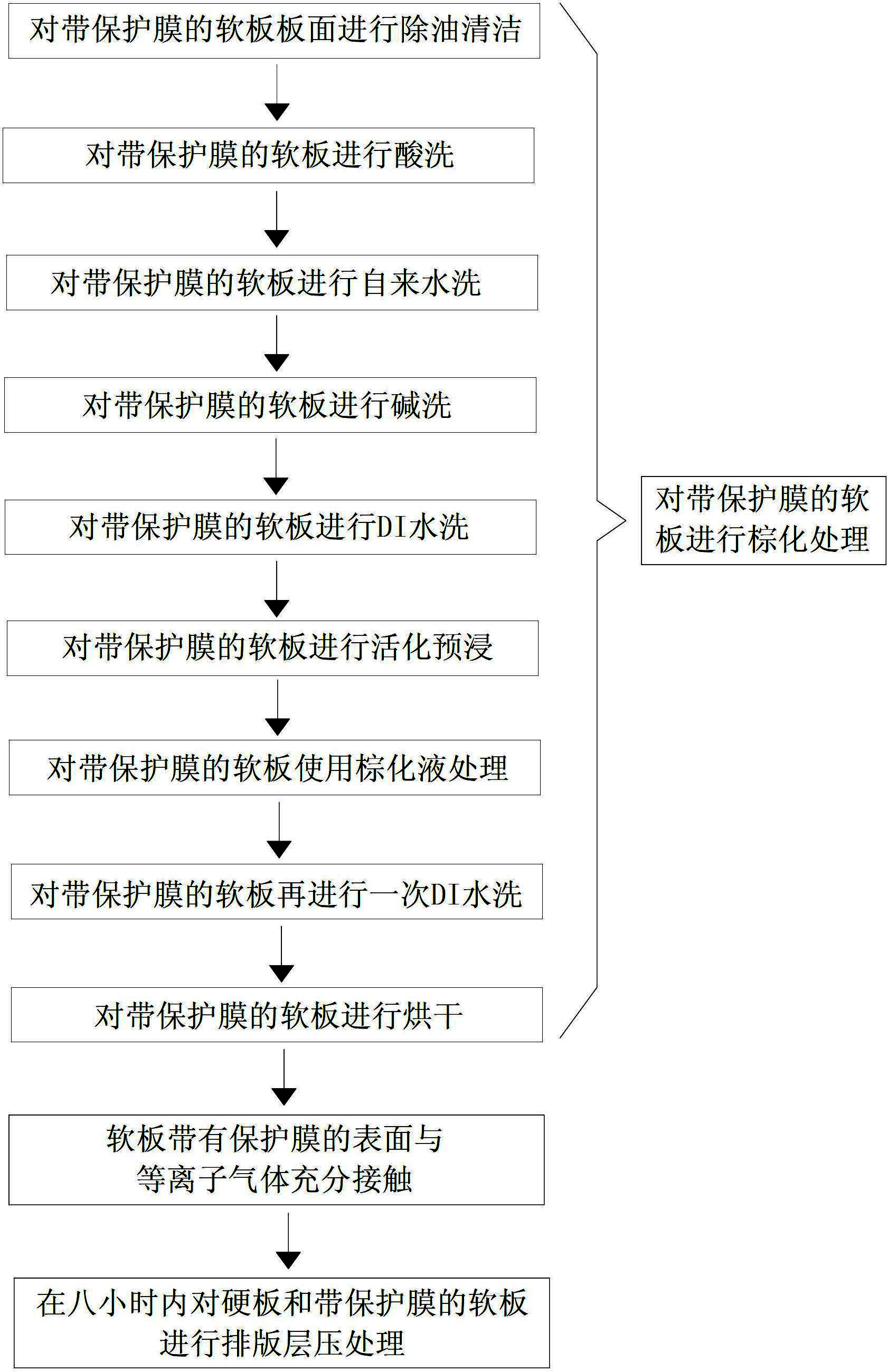

Method used

Image

Examples

Embodiment 1

[0042] In step A1, degreasing and cleaning are carried out at a temperature of 52°C and a pressure of 0.9 Bar, and the concentration of the inner bonded cleaning agent in the degreasing and cleaning solution is 85 mL / L;

[0043] In step A2, pickling is carried out at a temperature of 37°C and a pressure of 0.6 Bar. In the pickling solution, H 2 SO 4 Concentration 23mL / L, NaPS concentration 10g / L, Cu 2+ Concentration 20g / L;

[0044] In step A6, the activated presoak is carried out at a temperature of 37°C, and the concentration of the high-temperature material starter in the activated presoaked liquid is 17mL / L;

[0045] In step A7, the browning solution treatment is carried out at a temperature of 34°C; in the browning solution, the concentration of the inner layer bonding agent is 85mL / L, 50%H 2 O 2 Concentration is 19mL / L, H 2 SO 4 The concentration is 47mL / L, Cu 2+ Concentration 24g / L;

[0046] In step B, the plasma cleaning is carried out at a temperature of 80° ...

Embodiment 2

[0048] In step A1, degreasing and cleaning are carried out at a temperature of 51°C and a pressure of 0.6 Bar, and the concentration of the inner bonded cleaning agent in the degreasing and cleaning solution is 115mL / L;

[0049] In step A2, pickling is carried out at a temperature of 43°C and a pressure of 0.9 Bar. In the pickling solution, H 2 SO 4 Concentration 37mL / L, NaPS concentration 30g / L, Cu 2+ Concentration 10g / L;

[0050] In step A6, the activated presoak is carried out at a temperature of 43°C, and the concentration of the high-temperature material starter in the activated presoaked liquid is 23mL / L;

[0051]The browning solution treatment in step A7 is carried out at a temperature of 37°C; in the browning solution, the concentration of the inner layer bonding agent is 115mL / L, 50%H 2 O 2 Concentration is 24mL / L, H 2 SO 4 The concentration is 53mL / L, Cu 2+ Concentration 18g / L;

[0052] In step B, the plasma cleaning is carried out at a temperature of 100° ...

Embodiment 3

[0054] In step A1, degreasing and cleaning are carried out at a temperature of 51.5°C and a pressure of 0.8 Bar, and the concentration of the inner bonded cleaning agent in the degreasing and cleaning solution is 95mL / L;

[0055] In step A2, pickling is carried out at a temperature of 40°C and a pressure of 0.7 Bar. In the pickling solution, H 2 SO 4 Concentration 30mL / L, NaPS concentration 20g / L, Cu 2+ Concentration 15g / L;

[0056] In step A6, the activation pre-soaking is carried out at a temperature of 40°C, and the concentration of the high-temperature material starter in the activation pre-soaking solution is 20 mL / L;

[0057] The browning solution treatment in step A7 is carried out at a temperature of 35°C; in the browning solution, the concentration of the inner layer bonding agent is 100mL / L, 50%H 2 O 2 Concentration is 22mL / L, H 2 SO 4 The concentration is 50mL / L, Cu 2+ Concentration 25g / L;

[0058] In step B, the plasma cleaning is carried out at a tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com