ABS chromium-free coarsening solution, and preparation method and application thereof

A roughening liquid, ABS plastic technology, applied in liquid chemical plating, superimposed layer plating, coating and other directions, can solve the problem of product not roughening, foaming adhesion, difficult mass production, etc., to achieve good uniformity Roughening ability, damage reduction, low frequency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

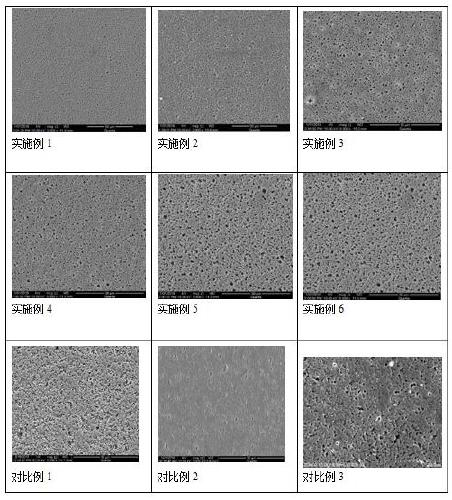

Image

Examples

Embodiment 1

[0032] Embodiment 1: The complete technological process of ABS coarsening

[0033] 1. Degreasing

[0034] Use a commercially available or disclosed degreasing liquid in the art, for example, a degreasing liquid prepared by using ENPREP142 degreasing powder provided by MacDermides Chemical Co., Ltd. Immerse the ABS sample in the prepared degreasing solution, stir and degrease at 60°C for 7 minutes, and then clean it with pure water. the bonding force between them.

[0035] 2. Pre-coarsening

[0036] Use a pre-roughening solution that is commercially available or disclosed in the art, or make your own pre-roughening solution. For example, 90 g of sodium hydroxide, 103 g of 1-methyl-2-pyrrolidone, and 18 g of ethylene glycol butyl ether were dissolved in deionized water, and the volume was adjusted to 1 L to prepare a pre-roughening solution.

[0037] The ABS plastic workpiece cleaned after degreasing is placed in it, pre-roughened at 40°C for 3 minutes, and then washed with ...

Embodiment 2

[0059] Embodiment 2: Change the roughening liquid composition

[0060] Change the composition of the roughening solution in step 3 of Example 1 to: dissolve 50g of manganese sulfate monohydrate in 200ml of water, stir well until dissolved, and slowly add 150ml of concentrated phosphoric acid and 150ml of methylsulfonate to it under the condition of a cold water bath acid, and finally slowly add 500ml of concentrated sulfuric acid. After the preparation is complete, add the fog suppressant to make the concentration 1ml / L. The temperature of the roughening solution is kept constant at 65°C, and the roughening solution is electrolyzed until the manganese oxide in it reaches 5g / L. The above-mentioned sample after acid leaching was immersed in the roughening solution after electrolysis for 10 minutes, and then cleaned with pure water.

[0061] Finally, a bright and smooth ABS sample with an electroplated copper layer of 40 microns was obtained.

Embodiment 3

[0062] Embodiment 3: Change the roughening liquid composition

[0063] Change the composition of the roughening solution in Step 3 of Example 1 to: dissolve 80g of manganese sulfate monohydrate in 200ml of water, stir well until dissolved, slowly add 200ml of concentrated phosphoric acid and 100ml of methylsulfonate to it under the condition of a cold water bath acid, and finally slowly add 500ml of concentrated sulfuric acid. After the preparation is complete, add the fog suppressant to make the concentration 3ml / L. Keep the temperature of the roughening solution at 60°C, and electrolyze the roughening solution until the manganese oxide in it reaches 8g / L. Immerse the sample after acid leaching in the roughening solution after electrolysis for 5 minutes, and then clean it with pure water.

[0064] Finally, a bright and smooth ABS sample with an electroplated copper layer of 40 microns was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com