Preparation method for coarsing P-GaN layer surface of LED

A surface roughening and manufacturing method technology, applied in the field of roughening technology, can solve the problems of complex process, high cost, unsatisfactory effect, etc., and achieve the effect of improved roughening effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The fabrication method of the present invention capable of roughening the surface of the P-GaN layer of the LED will be further described in detail through specific examples, wherein the method of the present invention is carried out by metal-organic chemical vapor deposition (MOCVD).

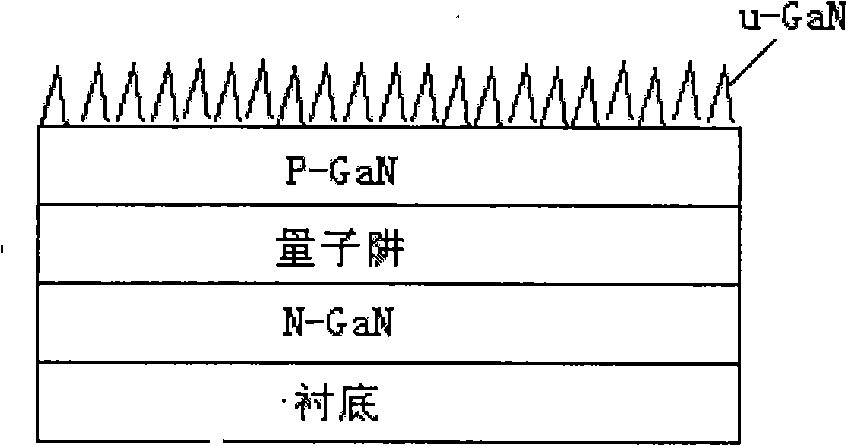

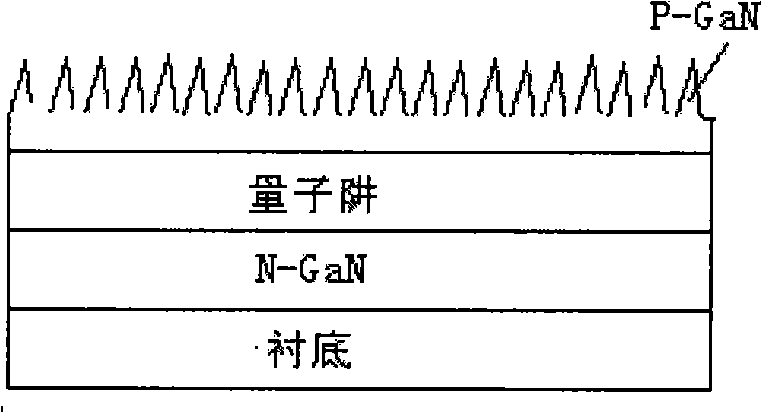

[0016] see Figure 2A to Figure 2B , the preparation method of the present invention that can roughen the surface of the P-GaN layer of LED mainly includes the following steps:

[0017] First, the N-GaN layer, the quantum well layer, the P-GaN layer, and the undoped roughened GaN layer (u-GaN) are sequentially grown on the semiconductor substrate, such as Figure 2A As shown, the non-doped roughened GaN layer is in the shape of a cone, and the apex angle of each formed cone can be adjusted by controlling the growth conditions to make it more pointed. In this embodiment, various layers are formed on the semiconductor substrate by using continuous growth. In addition, the material of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com