Method for treating surfaces of plates

A surface treatment and board technology, applied in secondary treatment of printed circuits, improvement of metal adhesion of insulating substrates, etc., can solve the problems of insufficient roughness, unable to further improve the tightness of PCB or dry film lamination, etc. Achieving better roughening effect and good binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in more detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it after studying this specification.

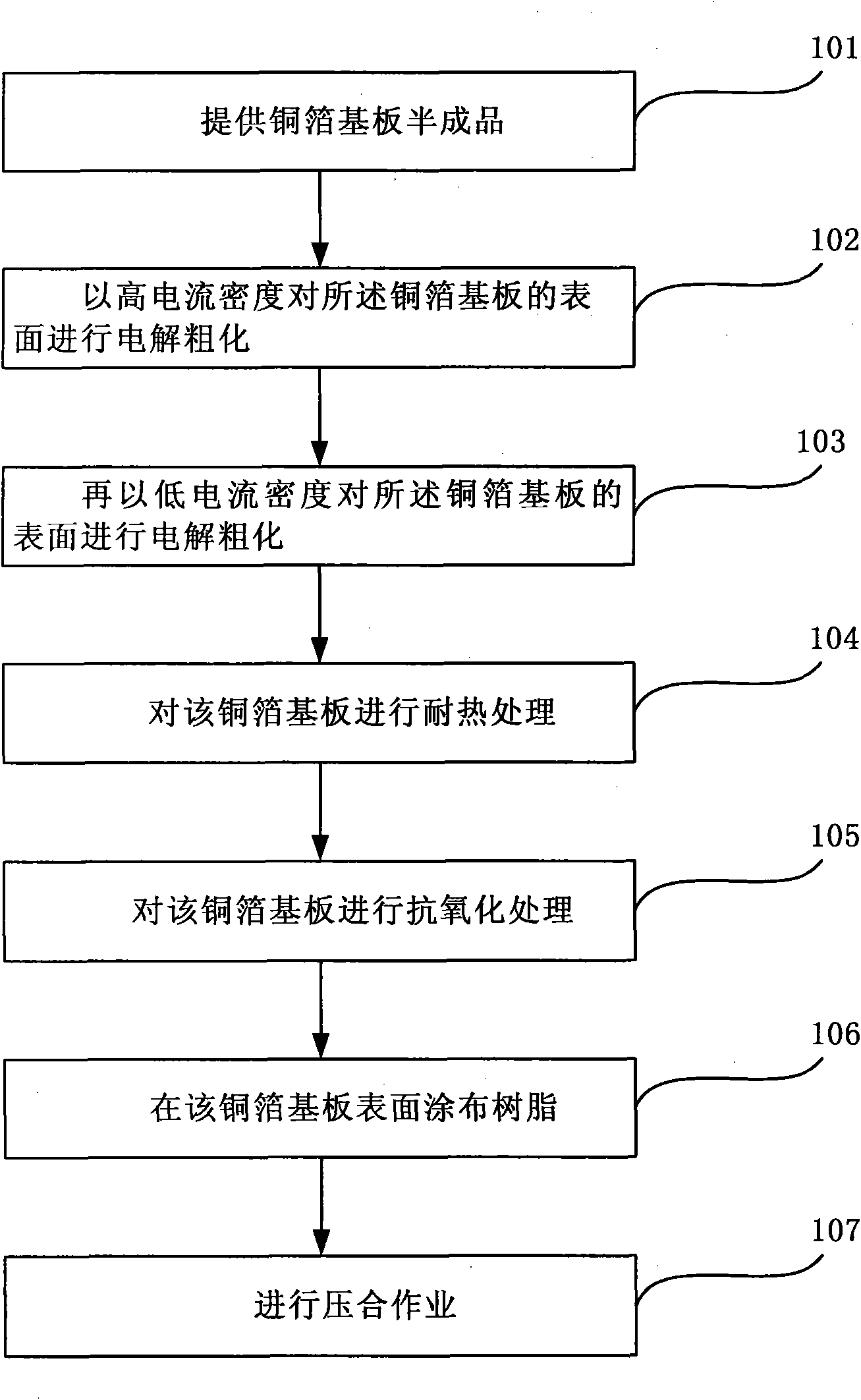

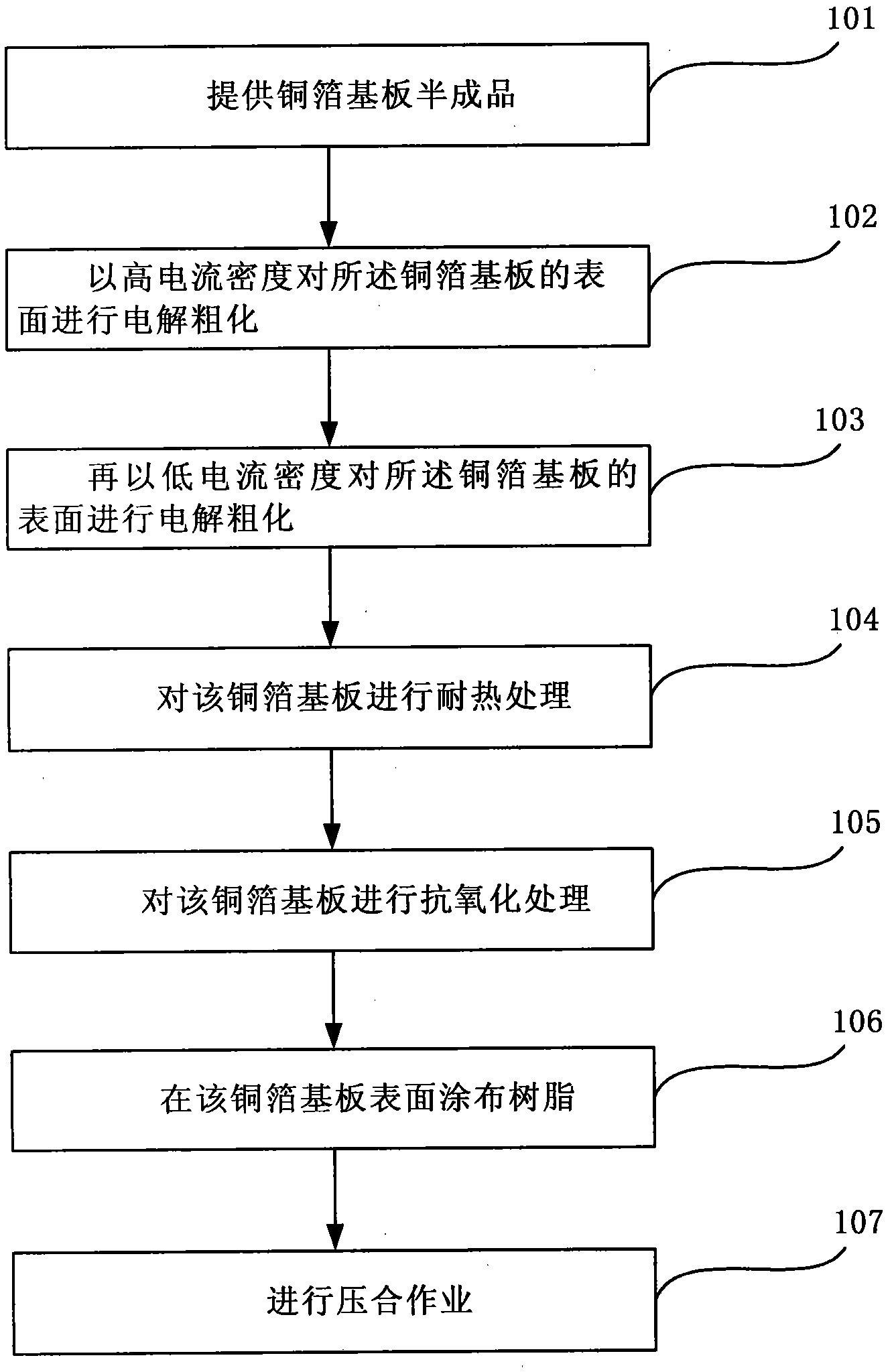

[0029] figure 1 It is a schematic flow chart of applying the board surface treatment method of the present invention to the surface treatment before PCB lamination. It includes the following steps:

[0030] Step 101, providing a semi-finished copper foil substrate;

[0031] Step 102, performing electrolytic roughening on the surface of the copper foil substrate with a high current density;

[0032] Step 103, performing electrolytic roughening on the surface of the copper foil substrate with a low current density;

[0033] Step 104, performing heat-resistant treatment on the copper foil substrate;

[0034] Step 105, performing anti-oxidation treatment on the copper foil substrate;

[0035] Step 106, coating resin on the surface of the copper foil substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com