Manufacture method of GaN (gallium nitride)-based LED (light emitting diode) chip with roughened surface

A technology for roughening the surface of LED chips, applied to electrical components, circuits, semiconductor devices, etc., can solve the inconsistencies in the effect of roughening the surface of GaN chips, the inability to accurately control the size and uniformity of the mask, and the inability to improve the light extraction efficiency. Uniformity and other issues, to achieve the effect of short preparation time, low cost and high light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

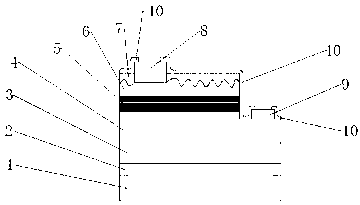

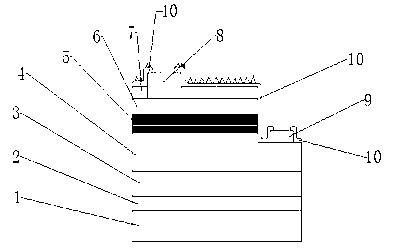

[0012] Refer to figure 1 , The present invention provides a method for manufacturing a GaN-based LED chip with a roughened surface, including the following steps:

[0013] Step 1: Using metal organic chemical vapor deposition (MOCVD) method, grow 20nmAlN, 2nm undoped GaN, 1nmGaN, 20nm current diffusion layer, (2nmInGaN+12.5nmGaN)*9MQW, 20nmP-GaN on semiconductor substrate 1 in sequence , Forming a GaN epitaxial wafer, wherein the semiconductor substrate 1 is sapphire, silicon, silicon carbide or metal;

[0014] Step 2: Put the GaN epitaxial wafer into PECVD, and quickly deposit silicon oxide or silicon nitride as a mask for etching on the surface of the P-GaN layer 6, or selectively deposit metals and other substances;

[0015] Step 3: Using the deposited nano-silicon oxide island as an etching mask, perform ICP (inductively coupled plasma) etching on the GaN epitaxial wafer, using Cl 2 , BCl 3 , Ar is used as an etching gas. After the etching is completed, the mask is removed with p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com