Polyetherimide chemical roughening and electroplating process

The technology of polyetherimide chemistry and polyetherimide is applied in the field of polyetherimide chemical roughening and electroplating process, and can solve the problems of unfavorable personal and operation safety of operators, large environmental pollution, and high equipment requirements. To achieve the effect of smooth appearance of workpiece, simple operation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

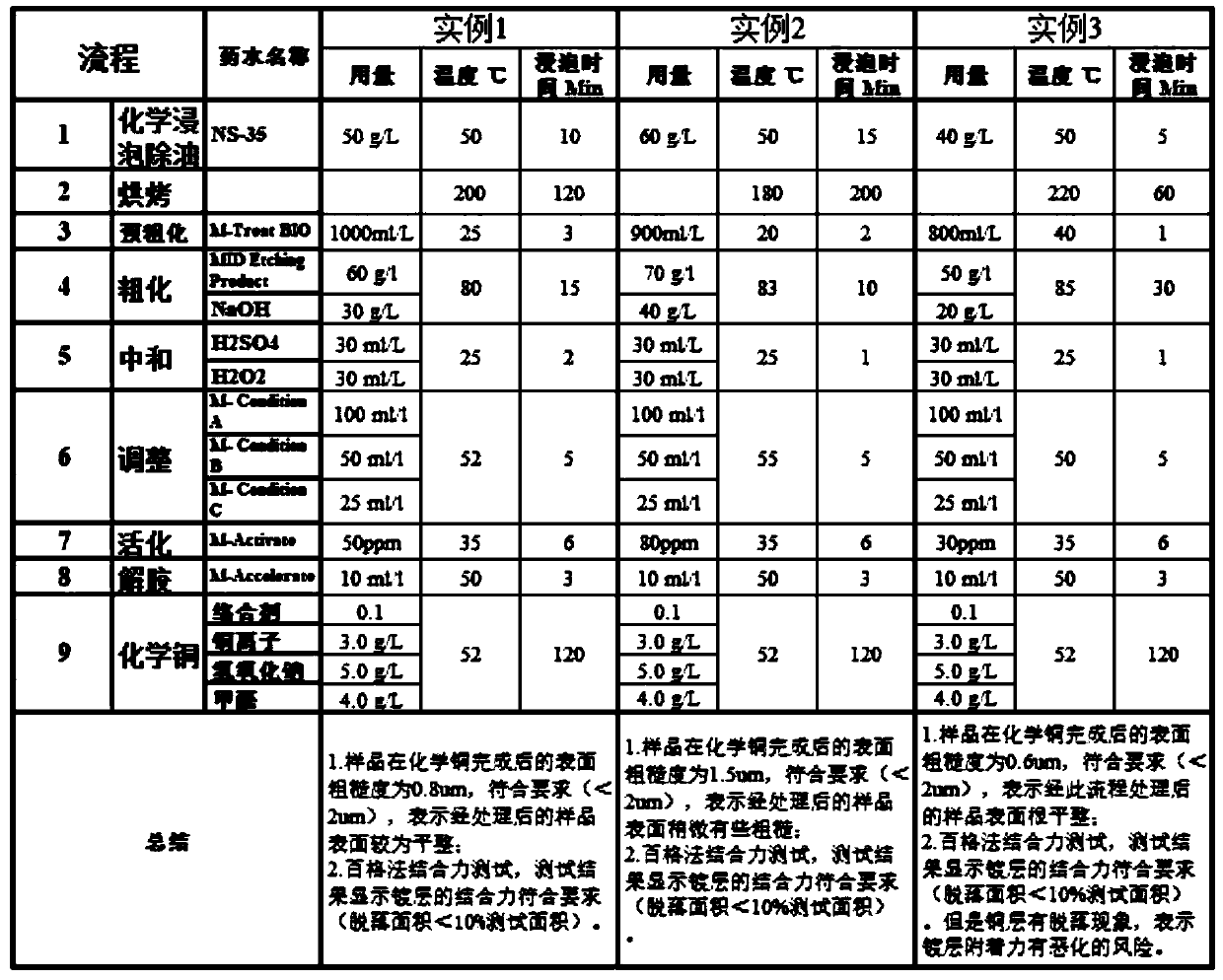

Embodiment 1

[0044] Chemical immersion degreasing: Use the degreasing powder ENPREP NS 35 from MacDermid Technology (Suzhou) Co., Ltd., with ultrasonic equipment, the operating concentration is 50g / L, the operating temperature is 50°C, and the soaking time is 10min.

[0045] It can be understood that this step can effectively remove the particle pollutants on the surface of the product, reduce the surface tension of the sample, and facilitate the infiltration of the subsequent liquid medicine.

[0046] Baking: Dry the polyetherimide in a high-temperature oven; the temperature is 200° C., and the time is 120 minutes.

[0047] It can be understood that baking can drive out the moisture in the sample, increase the bonding force of the coating, and prevent the deformation of the sample and the peeling off of the coating due to internal moisture.

[0048] Pre-roughening: Use the special pre-roughening agent for plastic products of Macderma Technology (Suzhou) Co., Ltd., the model is M-TreatBIO,...

Embodiment 2

[0067] Chemical immersion degreasing: Use the degreasing powder of ENPREP NS 35 from MacDermid Technology (Suzhou) Co., Ltd., with ultrasonic equipment, and the operating concentration is 60g / L. The operating temperature is 50°C, and the soaking time is 10 minutes.

[0068] It can be understood that this step can effectively remove the particle pollutants on the surface of the product, reduce the surface tension of the sample, and facilitate the infiltration of the subsequent liquid medicine.

[0069] Baking: Dry the polyetherimide in a high-temperature oven; the temperature is 180° C., and the time is 200 minutes.

[0070] It can be understood that baking can drive out the moisture in the sample, increase the bonding force of the coating, and prevent the deformation of the sample and the peeling off of the coating due to internal moisture.

[0071] Pre-roughening: Use the special pre-roughening agent for plastic products of Macderma Technology (Suzhou) Co., Ltd., the model i...

Embodiment 3

[0091] Chemical immersion degreasing: Use the model ENPREP NS 35 degreasing powder from MacDermid Technology (Suzhou) Co., Ltd., with ultrasonic equipment, the operating concentration is 40g / L, the operating temperature is 50°C, and the soaking time is 5min.

[0092] Baking: the temperature is 200°C, and the time is 60 minutes.

[0093] It can be understood that baking can drive out the moisture in the sample, increase the bonding force of the coating, and prevent the deformation of the sample and the peeling off of the coating due to internal moisture.

[0094] Pre-roughening: Use the special pre-roughening agent for plastic products of Macderma Technology (Suzhou) Co., Ltd., the model is M-TreatBIO, the operating concentration is 800ml / L, the operating temperature is 40°C, and the operating time is 1min.

[0095] The pre-roughening agent used in this embodiment is solvent-based, which can dissolve a small amount of plastic polymers on the surface of the polyetherimide, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com