Manufacturing method of gallium nitride based LED with vertical structure

A light-emitting diode, gallium nitride-based technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of poor reliability and light efficiency reduction of vertical GaN-based light-emitting diodes, etc., achieve good thermal stability, avoid Poor thermal stability, effects of maintaining luminous efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] A method for manufacturing a gallium nitride-based light-emitting diode with a vertical structure, the manufacturing steps of which are as follows:

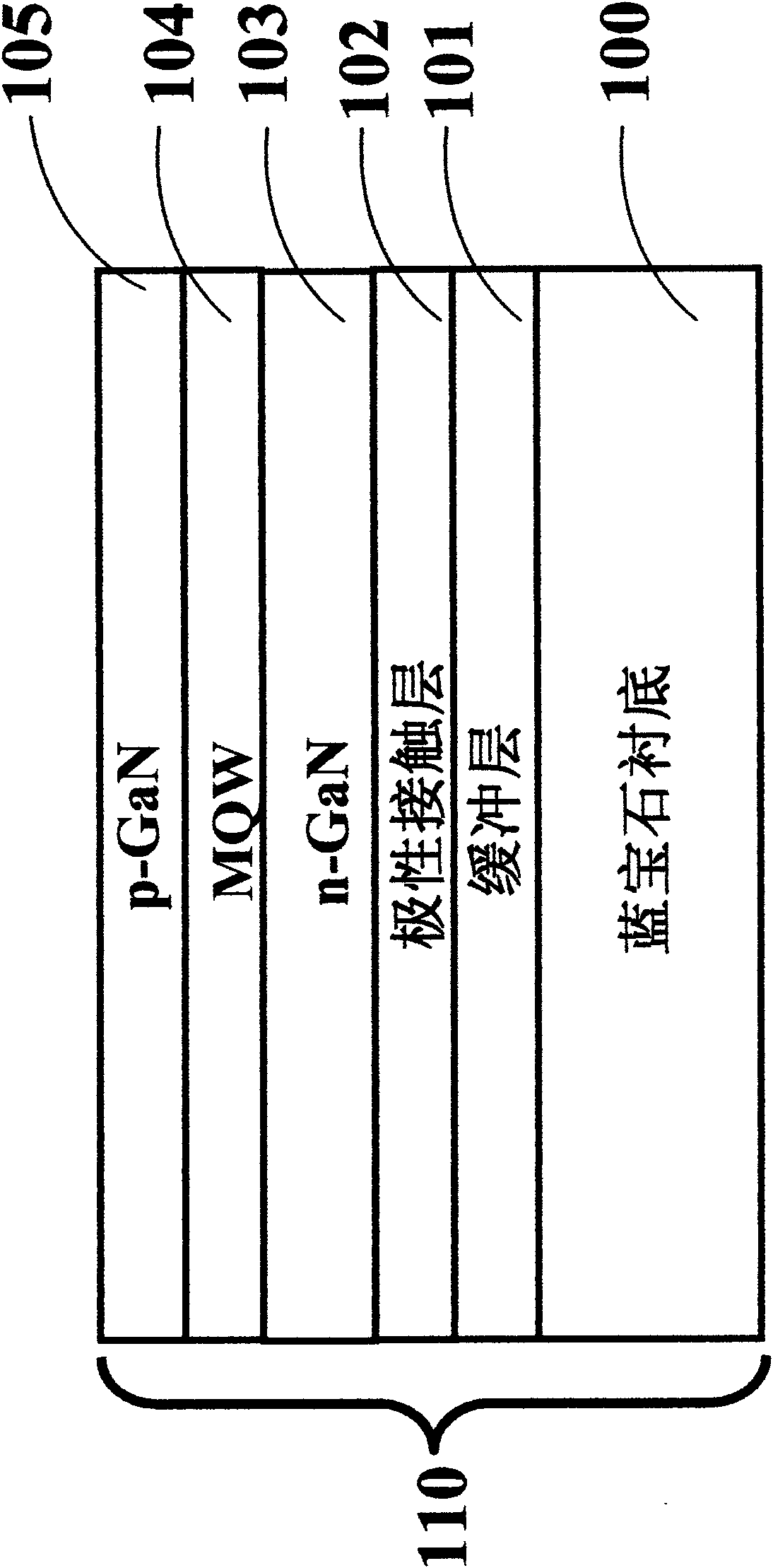

[0032] Such as Figure 1a As shown, making an epitaxial wafer 110 includes epitaxially growing a buffer layer 101, a polar contact layer 102, an n- GaN layer 103, multi-quantum well (MQW) active layer 104, and p-GaN layer 105, wherein the polar contact layer 102 is a nitrogen polar surface n-GaN, and the growth surface of n-GaN layer 103 is a gallium pole sex.

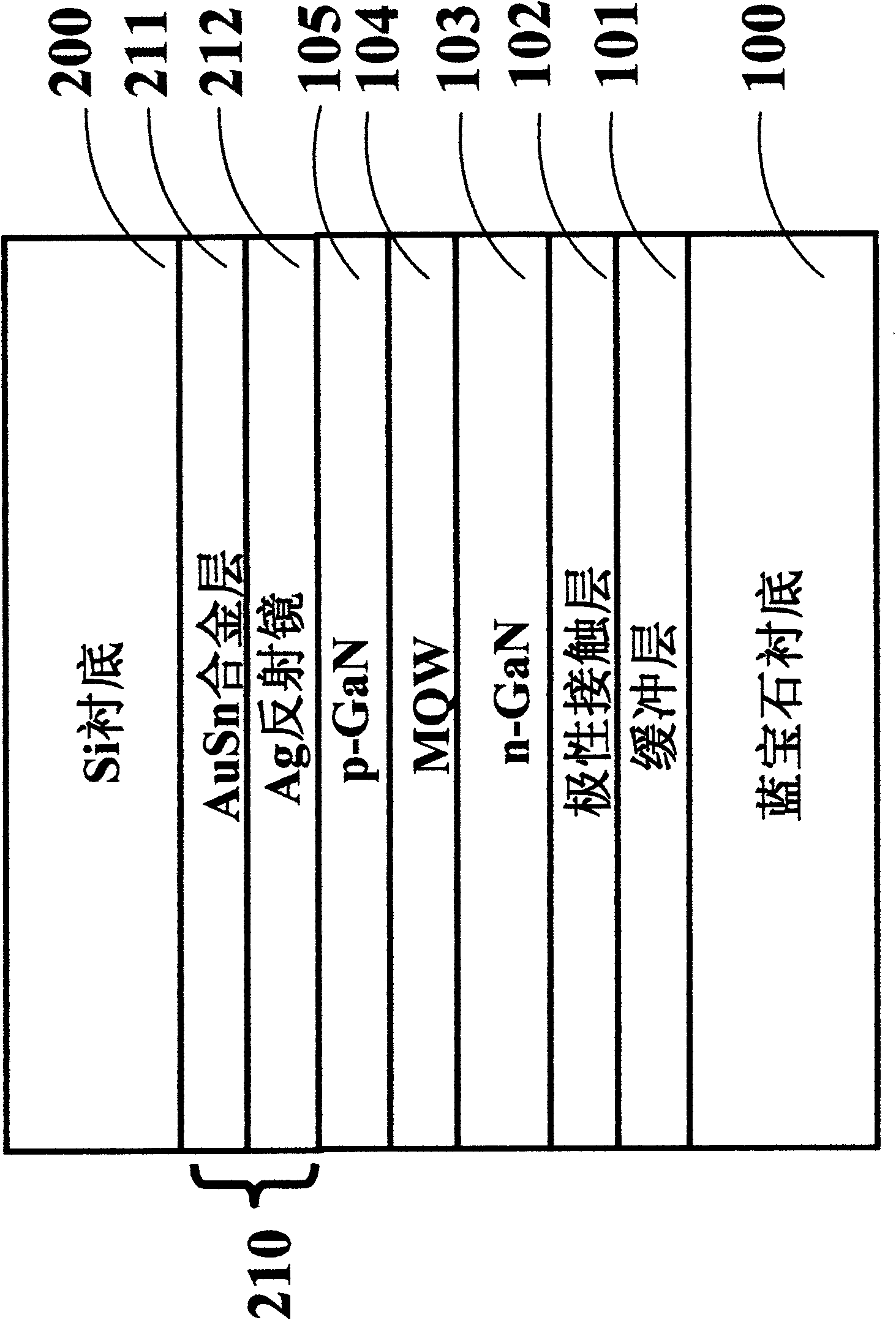

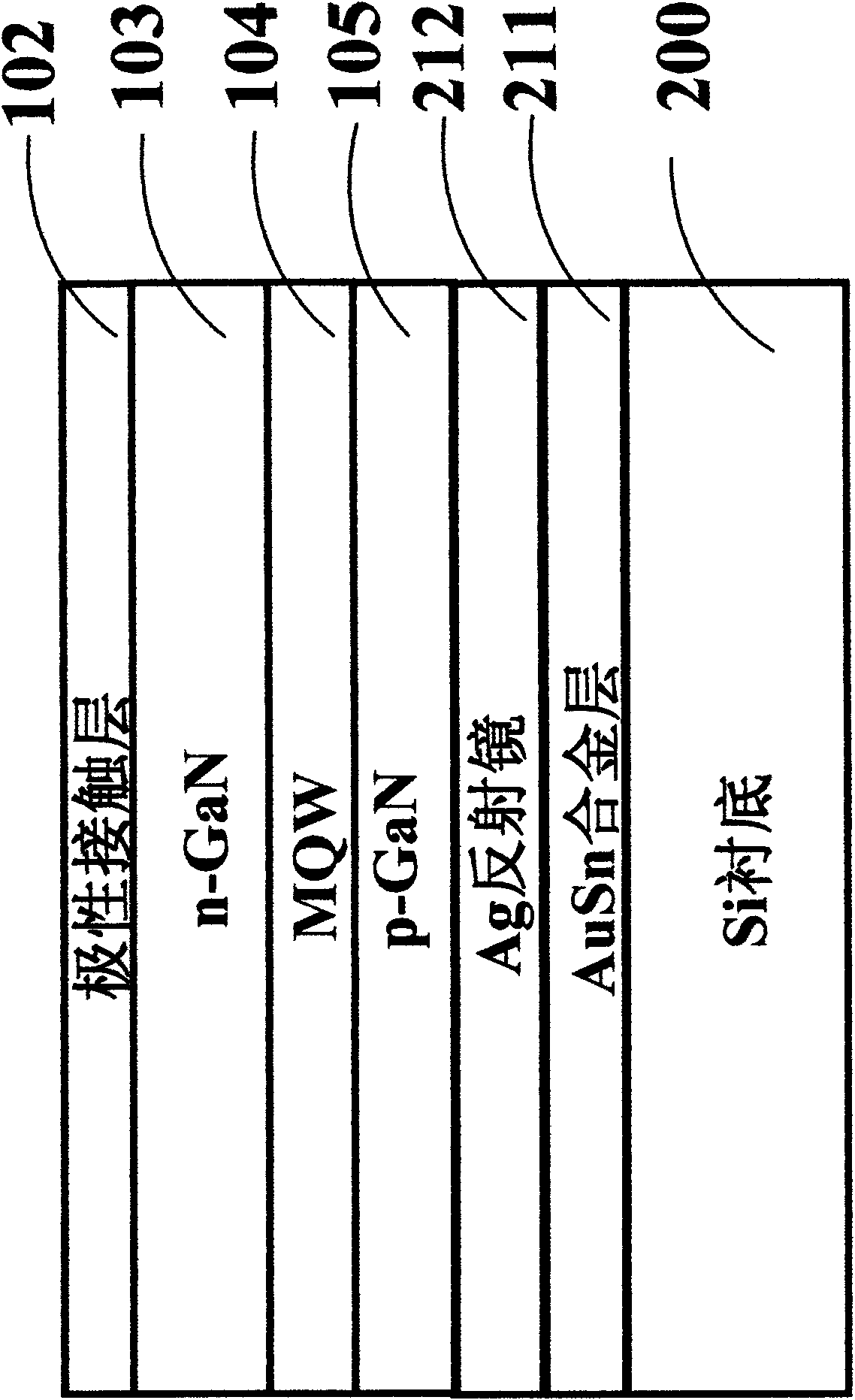

[0033] Such as Figure 1b As shown, a 100nm thick Ag mirror 211 is evaporated on the p-GaN layer 105, and the Ag mirror 211 not only plays a reflective role but also acts as an ohmic contact with the p-GaN layer 105; take a Si substrate 200 as Permanent substrate, on the Si substrate 200 evaporate a 2 micron thick AuSn (80: 20) alloy lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com