Transparent rubber modified polymethyl methacrylate resin composition and preparation method thereof

A technology of polymethyl methacrylate and resin composition, which is applied in the field of transparent rubber-modified polymethyl methacrylate resin composition and its preparation, can solve the problem of high light transmittance, low haze, Problems such as poor toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

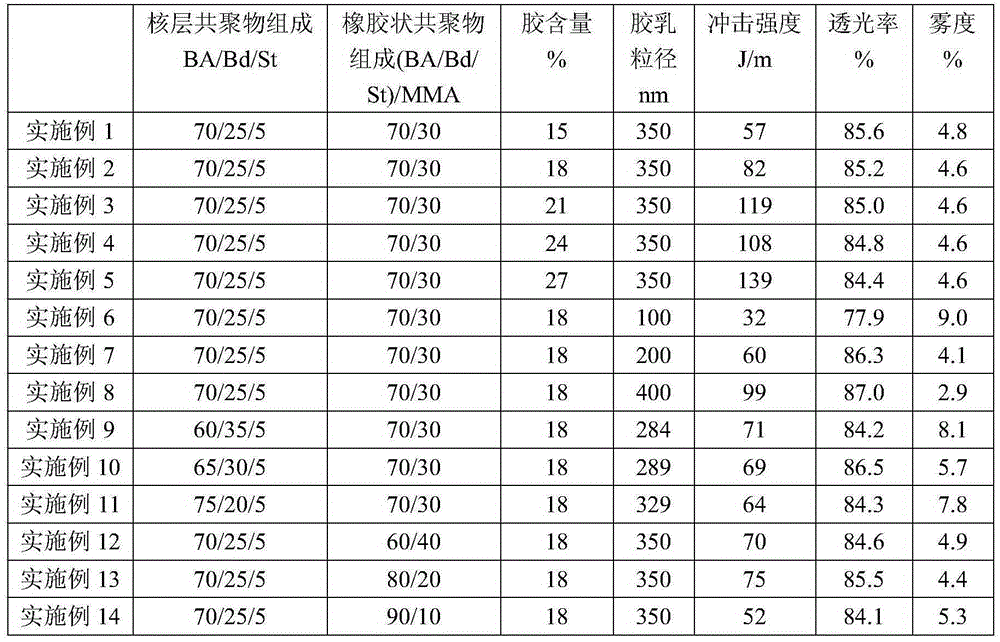

Examples

preparation example Construction

[0029] According to the present invention, the preparation method of described rubbery copolymer preferably comprises:

[0030] Pour 100-300 parts by weight of deionized water into the three-necked bottle, then add 0.1-0.7 parts by weight of sodium pyrophosphate, 0.3-0.9 parts by weight of glucose and 0.001-0.03 parts by weight of ferrous sulfate, and then add 0.01-0.10 parts by weight after fully dissolving Parts by weight of potassium hydroxide, 1-6 parts by weight of emulsifier and 100-300 parts by weight of core layer copolymer, put the three-necked bottle into a constant temperature water bath to keep the temperature at 60-70°C, and at the same time, feed nitrogen into the three-necked bottle and stir for 10 -20 minutes, take by weighing 10-40 parts by weight methyl methacrylate monomer and 0.10-0.35 parts by weight initiator to prepare methyl methacrylate dropwise monomer; described emulsifier is preferably rosin soap liquid and fatty acid soap The mixing emulsifier, the...

Embodiment 1

[0039] Preparation of core layer copolymer

[0040]The mixed emulsifier (weight ratio 1:1) of 150 parts by weight of rosin soap liquid and fatty acid soap, 1 part by weight of tert-dodecyl mercaptan, 1.27 parts by weight of potassium persulfate, 350 parts by weight of butyl acrylate monomer, 25 parts by weight Add parts by weight of styrene monomer and 217 parts by weight of deionized water to the reactor, then seal the reactor and add 125 parts by weight of butadiene monomer, place the reactor in a rotary constant temperature water bath, and react at 65°C for 26 hours , the reaction ends to obtain the core layer copolymer latex.

[0041] Preparation of rubbery copolymers

[0042] Inject 100 parts by weight of deionized water into a 1000ml three-necked bottle, then add 0.4 parts by weight of sodium pyrophosphate, 0.6 parts by weight of glucose and 0.01 parts by weight of ferrous sulfate in sequence, and after fully dissolving, add 0.10 parts by weight of potassium hydroxide a...

Embodiment 2

[0047] Preparation of core layer copolymer

[0048] The mixed emulsifier (weight ratio 1:1) of 150 parts by weight of rosin soap liquid and fatty acid soap, 1 part by weight of tert-dodecyl mercaptan, 1.27 parts by weight of potassium persulfate, 350 parts by weight of butyl acrylate monomer, 25 parts by weight Add parts by weight of styrene monomer and 217 parts by weight of deionized water to the reactor, then seal the reactor and add 125 parts by weight of butadiene monomer, place the reactor in a rotary constant temperature water bath, and react at 65°C for 26 hours , the reaction ends to obtain the core layer copolymer latex.

[0049] Preparation of rubbery copolymers

[0050] Inject 100 parts by weight of deionized water into a 1000ml three-necked bottle, then add 0.4 parts by weight of sodium pyrophosphate, 0.6 parts by weight of glucose and 0.01 parts by weight of ferrous sulfate in sequence, and after fully dissolving, add 0.10 parts by weight of potassium hydroxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com