Wear-bionic nano-ceramic composite artificial tooth and method for preparing same

A nano-ceramic, artificial tooth technology, applied in dental preparations, dentistry, dentures and other directions, can solve the problems of shortening the service life of artificial teeth, low chewing efficiency, short service life, etc., to reduce pain and economic burden, reduce wear speed, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

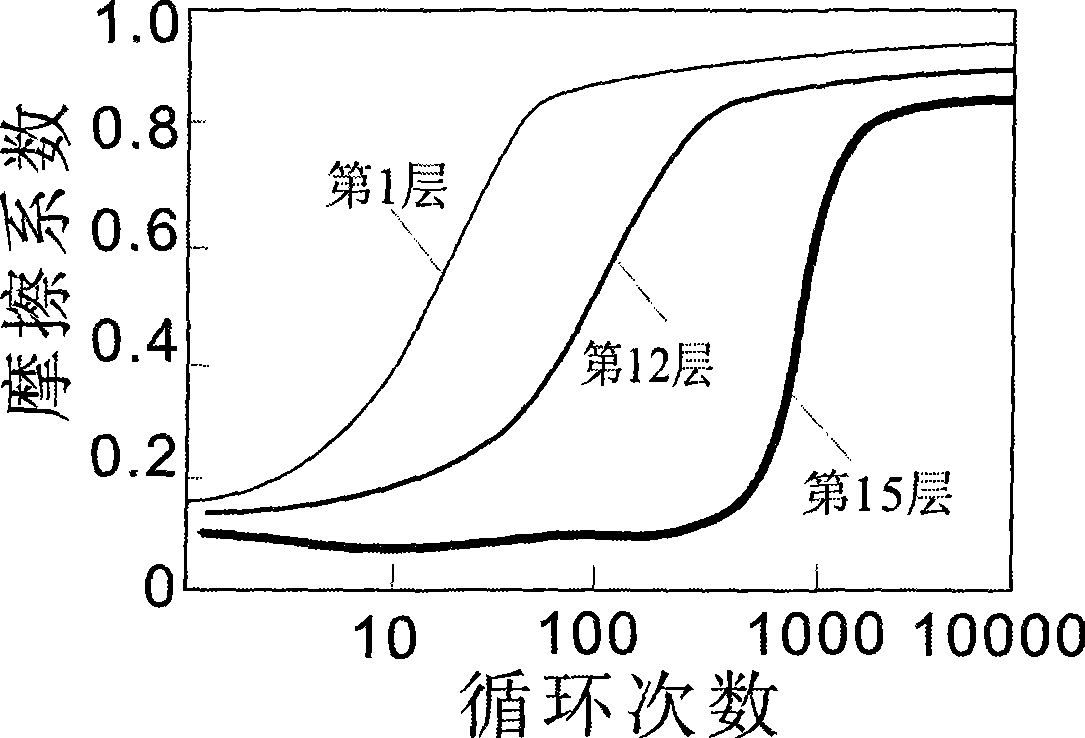

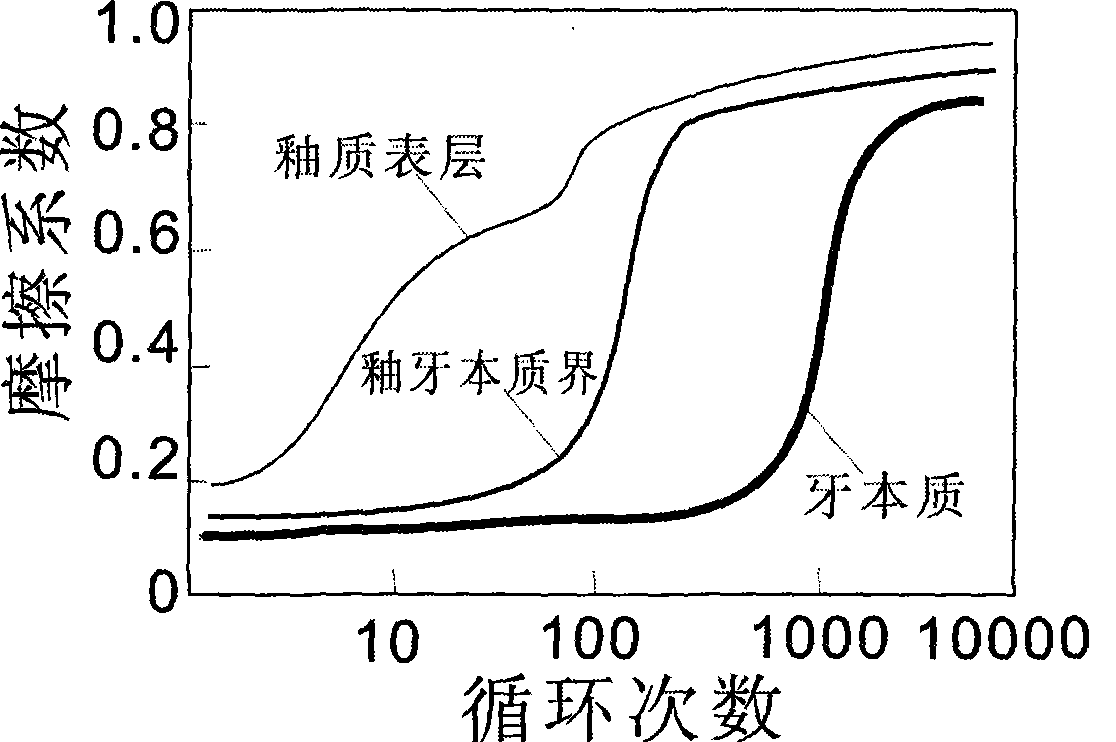

[0023] The composition of the artificial tooth of this example is: on the cap ridge of the artificial tooth made of polymethyl methacrylate (PMMA) resin, there are 15 layers of nano-ceramic / resin composite material layers covered, the innermost first layer The content of nano-ceramic material in the composite material layer is 10%, and the content of nano-ceramic in the composite material layer increases gradually from the inside to the outside, and the nano-ceramic content of the outermost layer is 30%; The thickness is 180-220 μm.

[0024] The resin in the nano ceramic / resin composite material layer in this example is a copolymer of methyl methacrylate and methyl acrylate (MMA-MA), wherein the mass ratio of methyl methacrylate to methyl acrylate is 2:1. The nano-ceramics in the nano-ceramic / resin composite material layer in this example are alumina ceramics with a diameter of 70-90 nm.

[0025] The concrete way of the preparation method of the nano-ceramic composite artific...

Embodiment 2

[0037]The structure and preparation method of the artificial tooth in this example and Example 1 are basically the same, the only difference is that in each layer of ceramic / resin composite material, the ratio of nano ceramics to resin is different, and the ratio of this example is shown in the following table Show:

[0038] Nano Ceramic / Resin Complex

[0039] In this example, layers 1-12 are also used to simulate the axon layer of natural teeth whose hardness gradually decreases from outside to inside; layer 13 simulates the sudden drop in hardness at the axon-dentin junction of natural teeth, and layers 14-15 Then, the hardness variation characteristic of the dentin layer of natural teeth is simulated.

Embodiment 3

[0041] The structure and preparation method of the artificial tooth of this example and Example 1 are basically the same, the difference is only: the number of layers of composite material is 12 layers, and in each layer of ceramic / resin composite material, the proportioning ratio of ceramic and resin is different, The proportions in this example are shown in the table below:

[0042] Nano Ceramic / Resin Complex

Composite material layers resin content Nano ceramic content The first layer (outermost layer) 70% 30% Second floor 71% 29%

[0043] the third floor 72% 28% fourth floor 74% 26% fifth floor 76% 24% sixth floor 77% 23% seventh floor 78% 22% eighth floor 79% 21% ninth floor 80% 20% tenth floor 85% 15% eleventh floor 88% 12% The twelfth floor (the innermost floor) 90% 10%

[0044] In this example, layers 1-9 simulate the axon layer of natural teeth whose hardne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com