Solderable low-temperature curing type functional silver paste and preparation method thereof

A curing and functional technology, applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, electrical components, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

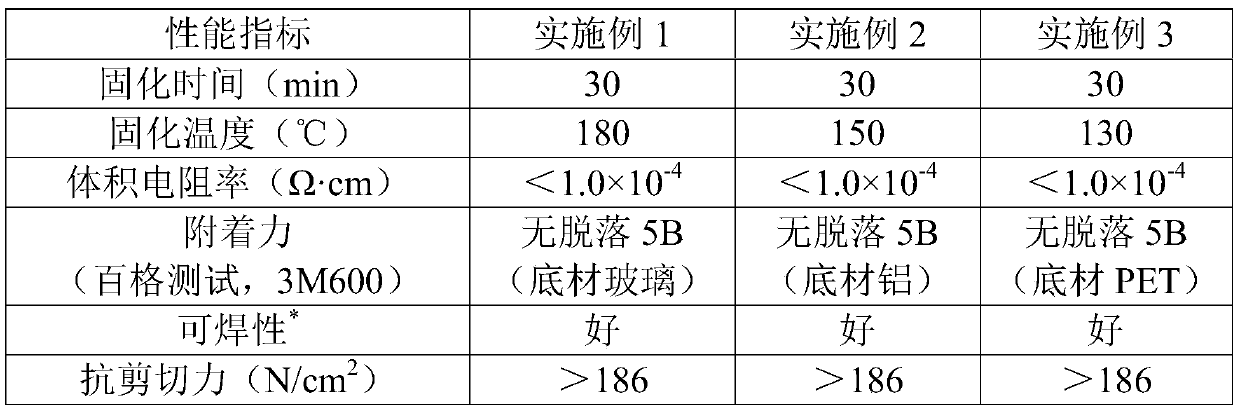

Examples

Embodiment 1

[0023] The modified polymethyl methacrylate PMMA resin is obtained by copolymerizing methyl methacrylate MMA, monomer methacrylic acid amide MAAM containing active hydrogen atoms and acrylic acid AA.

[0024] Get 85wt% of the above-mentioned modified polymethyl methacrylate PMMA resin, add 10wt% propylene methacrylate crosslinking agent and 5wt% bis(dioctyloxypyrophosphate) ethylene titanate, use high-speed dispersion agent dispersed to make 10wt% organic vehicle.

[0025] Add 85wt% tap density 3.0~4.0g / cm in the organic vehicle 3 , burning loss rate2 / g, the maximum sheet diameter < 25 micron flake silver powder, pre-mixed into a slurry with a double planetary mixer, ground and dispersed with a three-roll mill, and finally degassed under reduced pressure to obtain the finished product.

Embodiment 2

[0027] Take 75wt% of the modified polymethyl methacrylate PMMA resin of Example 1 and mix it with 10wt% organic solvent, stir it with a high-speed disperser, and the temperature does not exceed 70°C. After the resin is completely dissolved, it is cooled to room temperature, and 10wt% methacrylic acid is added Acrylic ester crosslinking agent and 5wt% bis(dioctyloxypyrophosphate) ethylene titanate are dispersed with a high-speed dispersant to prepare 15wt% organic vehicle. Wherein the organic solvent is composed of 20% dimethyl succinate, 60% dimethyl glutarate and 20% dimethyl adipate in mass percent.

[0028] Add 90wt% flaky silver powder / spherical silver powder (Wt:Wt=9:1) to the organic vehicle, and the tap density of flaky silver powder is 4.0-6.0g / cm 3 , burning loss rate2 / g, the largest sheet diameter 3 , burning loss 0.9%, specific surface area 0.5 ~ 1.0m 2 / g, the maximum particle size is less than 6 microns, pre-mixed into a slurry with a double planetary mixer, gro...

Embodiment 3

[0030] Take 95wt% of the modified polymethyl methacrylate PMMA resin in Example 1, add 5wt% propylene methacrylate crosslinking agent, and disperse with a high-speed dispersant to prepare 5wt% organic vehicle.

[0031] Add 95wt% flaky silver powder / spherical silver powder (Wt:Wt=8:2) to the organic vehicle, and the tap density of flaky silver powder is 4.0-6.0g / cm 3 , burning loss rate2 / g, the largest sheet diameter 3 , burning loss 0.9%, specific surface area 0.1~0.5m 2 / g, the maximum particle size is less than 6 microns, pre-mixed into a slurry with a double planetary mixer, ground and dispersed with a three-roll mill, and finally degassed under reduced pressure to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com