Infrared ray-penetrable polymethyl methacrylate composition

A polymethyl methacrylate and infrared technology, applied in the field of polymethyl methacrylate composition, can solve the problem of high manufacturing cost and achieve the effects of low manufacturing cost, excellent mechanical properties and high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

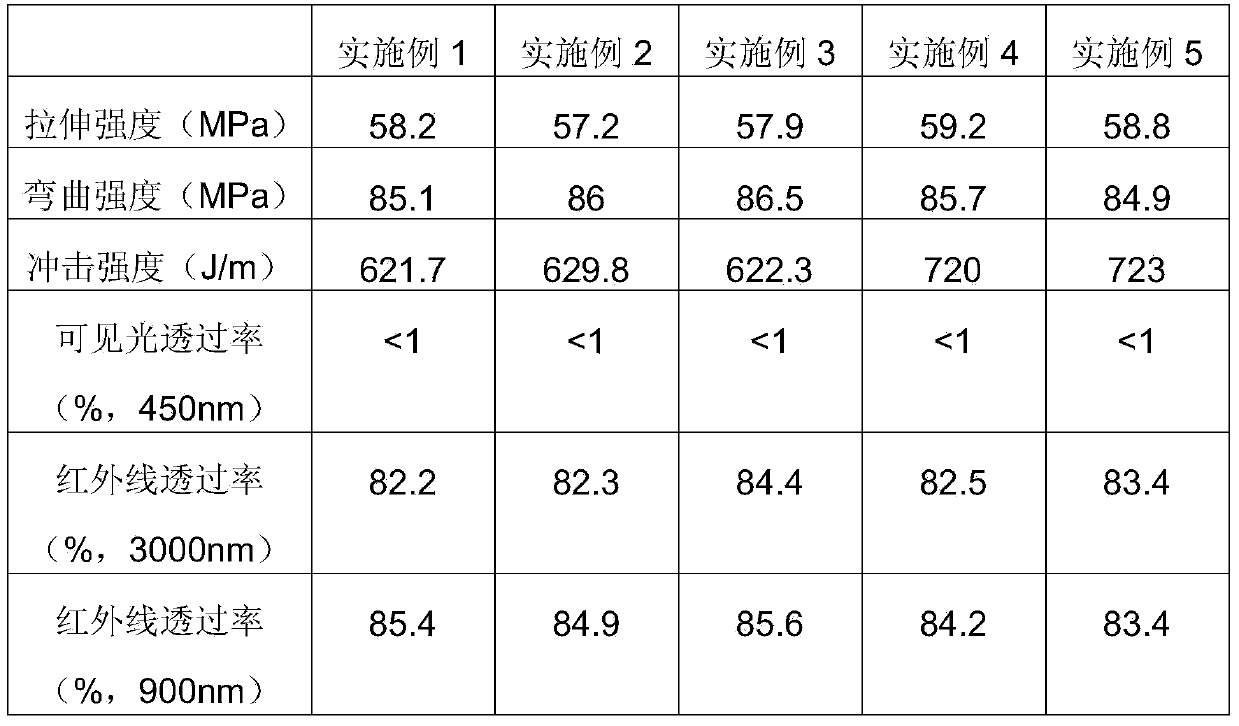

Examples

Embodiment 1

[0030] Weigh 98.5Kg of polymethyl methacrylate, 0.2Kg of calcium fluoride, 0.3Kg of magnesium fluoride, 1Kg of organic silicon surface modifier and 0.2Kg of carbon black;

[0031] Mix polymethyl methacrylate and carbon black evenly, and perform surface treatment on calcium fluoride, magnesium fluoride and organic silicon surface modifier;

[0032] Stir each material at high speed (900r / min) in a high stirring pot for 5 minutes. After preliminary mixing, add it into the co-rotating twin-screw extruder from the feeding port, and the co-rotating twin-screw extruder rushes into the feed section to the machine head The temperature is 190°C, 220°C, 255°C, 265°C, 255°C, 250°C, 245°C, 240°C in sequence, the die head temperature is 260°C, the material residence time is 3min, the pressure is 20MPa, and the screw speed is 350 rpm. After being extruded by a co-rotating twin-screw extruder, it is granulated and packaged to obtain an infrared-transmitting polymethyl methacrylate composition...

Embodiment 2

[0034] Weigh polymethyl methacrylate 98.3Kg, calcium fluoride 0.2Kg, zinc fluoride 0.3Kg, organosilicon surface modifier 1Kg and iron oxide 0.2Kg; Prepare the polymethylmethacrylate through the infrared in the same way as in Example 1 methacrylate compositions.

Embodiment 3

[0036] Weigh 98.6Kg of polymethyl methacrylate, 0.2Kg of calcium fluoride, 0.3Kg of zinc fluoride, 1Kg of organic silicon surface modifier, 0.2Kg of iron oxide and 2-hydroxy-4-n-octyloxybenzophenone 0.1Kg; Prepare the infrared-transmitting polymethyl methacrylate composition in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| infrared transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com