Preparation method of crosslinked polymethyl methacrylate resin microspheres with narrow particle size distribution

The technology of polymethyl methacrylate and methyl methacrylate is applied in the field of preparation of polymethyl methacrylate resin microspheres, which can solve the problems of unstable silica gel matrix, limit the application of industrial preparative chromatography technology, etc. Simple, easy to mass industrial production, the effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

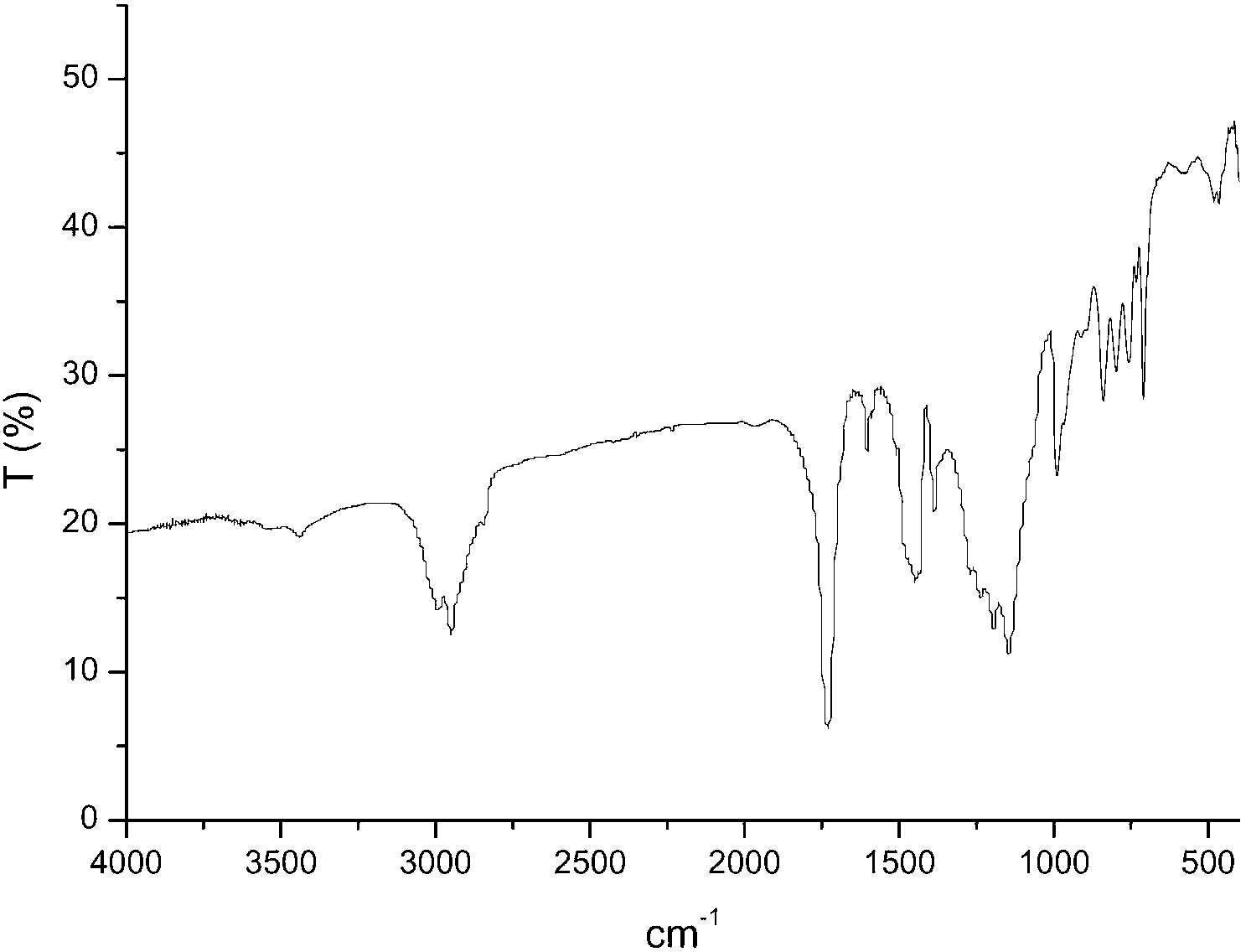

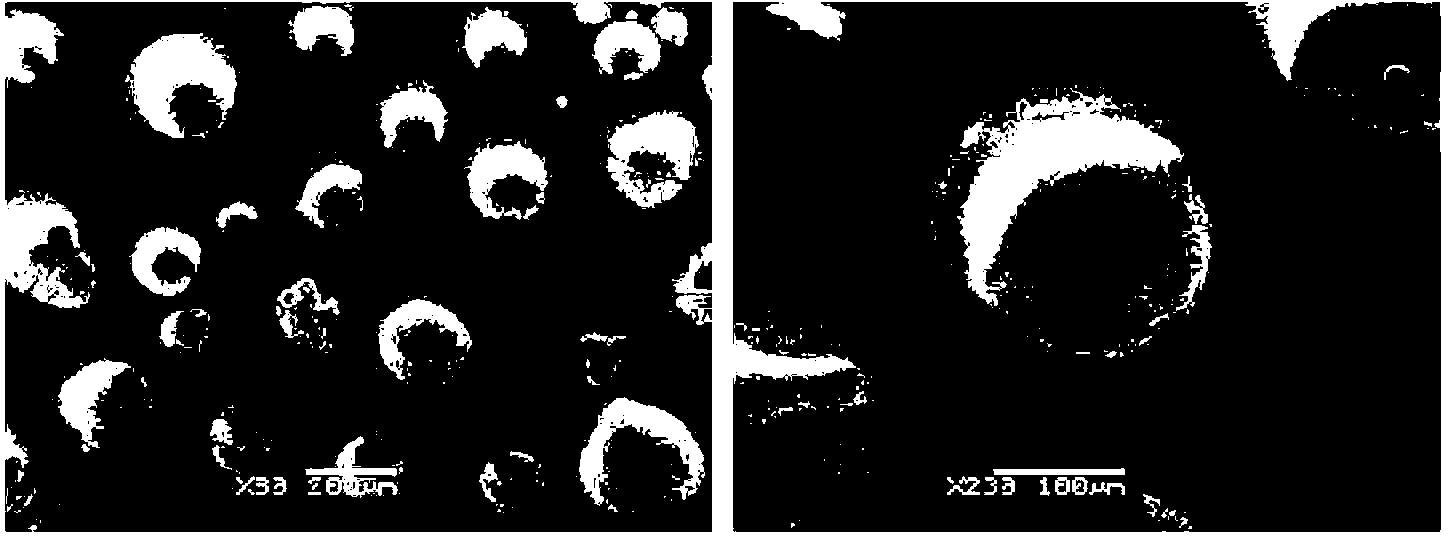

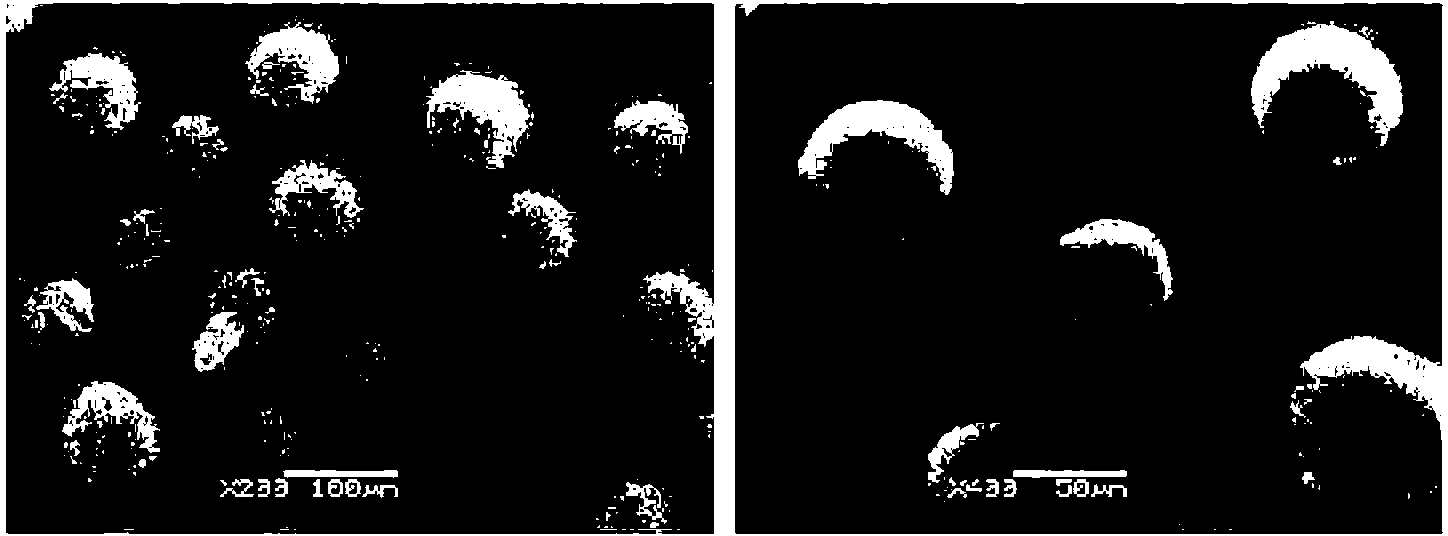

[0031] The preparation method of the cross-linked polymethyl methacrylate resin microsphere of embodiment 1 narrow particle size distribution

[0032] 1) Methyl methacrylate and divinylbenzene were washed three times with 20% NaOH aqueous solution respectively, and then washed three times with deionized water for later use;

[0033] 2) According to the weight ratio of methyl methacrylate monomer and crosslinking agent is 80:20, after fully mixing 4g methyl methacrylate monomer, 1g crosslinking agent divinylbenzene and 2.5g porogen toluene , add 0.2g initiator azobisisobutyronitrile to fully dissolve to obtain liquid A;

[0034] 3) Dissolve the dispersant gelatin and surfactant OP-10 in water completely to obtain liquid B. In liquid B, the concentration of gelatin is 3 g / L, and the concentration of OP-10 is 0.3 g / L;

[0035] 4) Add liquid A into liquid B, stir at a speed of 900 rpm, heat up to 75-85°C during the reaction, and keep the temperature at this temperature for 4-5 ho...

Embodiment 2

[0039] The preparation method of the cross-linked polymethyl methacrylate resin microsphere of embodiment 2 narrow particle size distribution

[0040] 1) Methyl methacrylate and divinylbenzene were washed three times with 20% NaOH aqueous solution respectively, and then washed three times with deionized water for later use;

[0041] 2) According to the weight ratio of methyl methacrylate monomer and crosslinking agent as 80:20, after fully mixing 4g methyl methacrylate monomer, 1g crosslinking agent divinylbenzene and 2.5g porogen xylene , add 0.2g initiator benzoyl peroxide to fully dissolve to obtain liquid A;

[0042] 3) Dissolve the dispersant gelatin and surfactant AEO-9 in water completely to obtain liquid B. In liquid B, the concentration of gelatin is 3 g / L, and the concentration of AEO-9 is 0.3 g / L;

[0043]4) Add liquid A into liquid B, stir at a speed of 900 rpm, heat up to 75-85°C during the reaction, and keep the temperature at this temperature for 4-5 hours to o...

Embodiment 3

[0046] The preparation method of the cross-linked polymethyl methacrylate resin microsphere of embodiment 3 narrow particle size distribution

[0047] 1) Methyl methacrylate and divinylbenzene were washed three times with 20% NaOH aqueous solution respectively, and then washed three times with deionized water for later use;

[0048] 2) According to the weight ratio of methyl methacrylate monomer and crosslinking agent is 60:40, after fully mixing 1.5g methyl methacrylate monomer, 1g crosslinking agent divinylbenzene and 2.5 g porogen toluene , add 0.2 g initiator azobisisobutyronitrile to fully dissolve to obtain liquid A;

[0049] 3) Dissolve the dispersant gelatin and surfactant OP-10 in water completely to obtain liquid B. In liquid B, the concentration of gelatin is 2 g / L, and the concentration of OP-10 is 0.2 g / L;

[0050] 4) Add liquid A into liquid B, stir at a speed of 800 rpm, heat up to 75-85°C during the reaction, keep the temperature at this temperature for 4-5 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com