Preparation method of phosphorus-containing flame-retardant polymethyl methacrylate resin

A technology of polymethyl methacrylate and polymethacrylic acid is applied in the fields of polymer chemistry and polymers, phosphorus-containing flame retardant resins and their preparation, and can solve problems such as flammability and thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The preparation steps of phosphorus-containing flame-retardant polymethacrylic resin are:

[0014] In a reaction vessel equipped with a stirrer, a thermometer and a glass tube, add the formula amount of methyl methacrylate, tris((6-oxo-6H-dibenzo[c,e][1,2]oxophosphorus Heterohexacyclo-6-yl) methyl) phosphate and initiator benzoyl peroxide. Stir at 85.2°C for about 52 minutes. The system becomes viscous. Then pour the prepolymer into the mold and cool to about 40°C. The temperature is kept for 6 hours, and then the temperature is increased to 80°C for 12 hours to obtain a flame-retardant polymethacrylic resin.

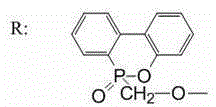

[0015] According to the above-mentioned preparation method of phosphorus-containing flame-retardant polymethyl methacrylate resin, in terms of mass percentage, three ((6-oxo-6H-dibenzo[c,e][1,2] oxygen The formula of phosphahexyl-6-yl) methyl) phosphate is:

[0016] 6-(Hydroxymethyl)-6H-dibenzo[c,e][1,2]oxahexacyclo-6-oxide 9.87%~11.22%, phosphorus oxychloride 10.11%~...

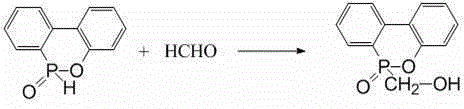

Embodiment 1

[0043] In a reactor equipped with a stirrer, a thermometer, and a reflux condenser, 56.76 kg of xylene and 35.64 kg of DOPO are added and heated with stirring. DOPO is completely dissolved when the temperature is 85°C. Keep the same temperature, add 4.95kg paraformaldehyde in batches within 2h. After the feeding was completed, the temperature was raised to 120°C, the system refluxed, and the system turned from clear to turbid. Then keep the temperature for 6h and discharge. Wash the precipitate with a large amount of xylene while it is hot and filter with suction. Then place it at 120°C for 48h. A white powder HDOPO is obtained.

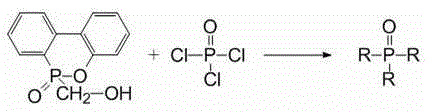

Embodiment 2

[0045] Add 5.57kg HDOPO and 32.48g dichloromethane solution to a reactor equipped with a thermometer and a gas pipe, and stir for 30min at 25°C. The temperature of the system was lowered to -8°C, 2.49g of triethylamine was added, stirred and kept for 30 minutes. Then began to drop a mixed solution of 5.78 kg of phosphorus oxychloride and 9.28 kg of methylene chloride. After the dripping is completed, keep the temperature at a low temperature for 2 hours, then heat to 25°C and stir for 6 hours. Discharge, evaporate the solvent and triethylamine in the system. The product was recrystallized to obtain the pure product TOPMP.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com