Preparation method for polymethyl methacrylate resin with high heat resistance

A polymethyl methacrylate, high heat resistance technology, applied in the field of polymer material preparation, can solve the problems of complex post-treatment process, toxic product properties of solvents, etc., and achieve shortened polymerization reaction time, good performance, and excellent heat resistance. and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A kind of preparation method of high heat-resistant polymethyl methacrylate resin provided by the invention adopts continuous solution polymerization, comprising:

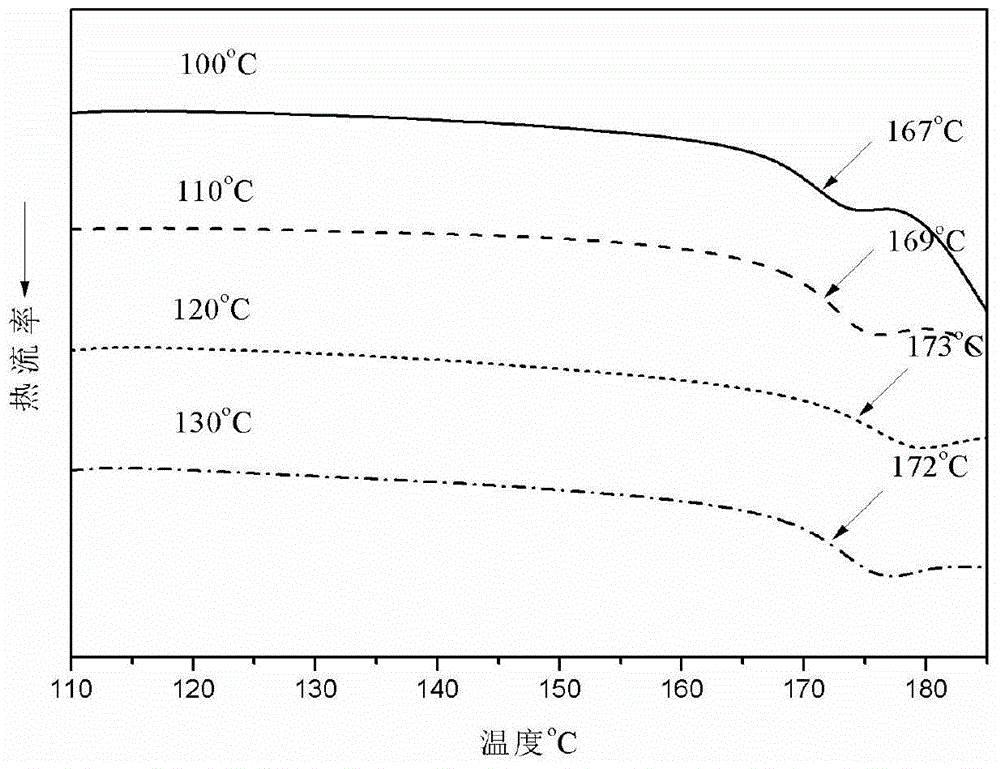

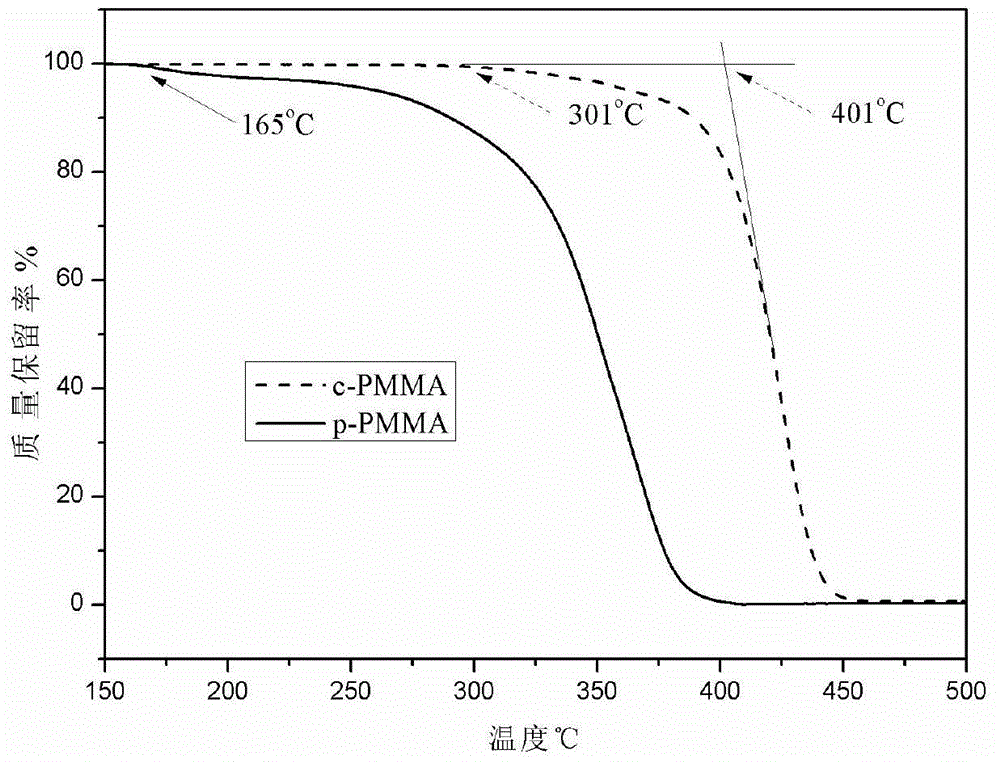

[0021] Step 1: Mix methyl methacrylate, acrylamide monomer, solvent, initiator and chain transfer agent to form a mixed solution, continuously inject the mixed solution into the reaction kettle through the feeding pump, and carry out polymerization at 100-160°C React for 3 to 4 hours to obtain a reaction mixture;

[0022] Step 2: Start the discharge melt pump and the devolatilization extruder, enter the reaction mixture obtained in step 1 from the reaction kettle through the discharge melt pump into the devolatilization extruder for devolatilization, and start the feeding pump at the same time to adjust The amount of feed and the amount of output are kept consistent to obtain the polymethyl methacrylate resin.

[0023] According to the present invention, methyl methacrylate, acrylamide monomer, solvent, ini...

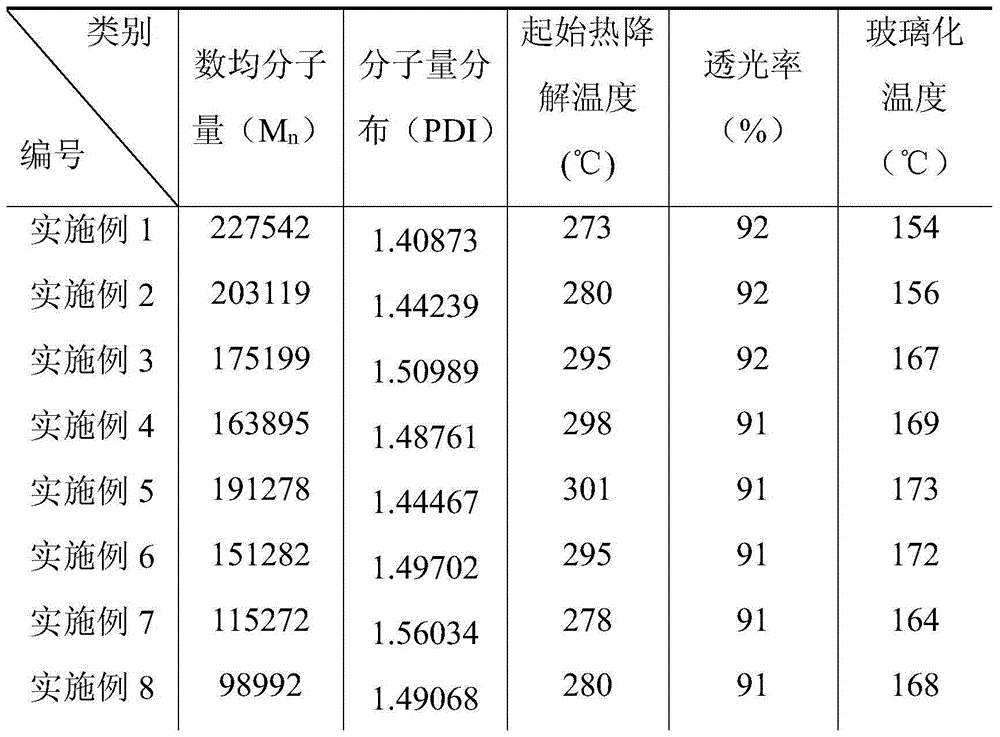

Embodiment 1

[0033] 90 parts by weight of monomer I methyl methacrylate, 10 parts by weight of monomer II methacrylamide, 20×10 -6 The initiator AIBME of parts by weight, the solvent ethanol that does not add chain transfer agent and 20 parts by weight are made into 6kg solution through metering pump and join polymerization reactor, and feed nitrogen in the polymerization kettle in order to get rid of dissolved oxygen and The air in the reaction kettle was removed, then the stirring paddle and the built-in gas phase condenser were opened, and heated in an oil bath, and reacted at 100°C for 3 hours to obtain a reaction mixture;

[0034] Start the discharge melt pump and the devolatilization extruder, the reaction mixture obtained enters the devolatilization extruder from the reaction kettle through the discharge melt pump at 6kg / hr and carries out devolatilization 2min, and starts the feed pump simultaneously, adjusts The amount of feed and the amount of output, so that the feed rate and ou...

Embodiment 2

[0036] 85 parts by weight of monomer I methyl methacrylate, 15 parts by weight of monomer II methacrylamide, 30×10 -6 Initiator AIBN, chain transfer agent normal dodecyl mercaptan 20 * 10 parts by weight -6 and 20 parts by weight of solvent ethanol are made into 6kg solution and added to the polymerization reactor through a metering pump, and nitrogen gas is passed into the polymerization reactor to get rid of the dissolved oxygen in the mixed material and the air in the reactor, and then the stirring paddle, the built-in The gas phase condenser was opened, heated in an oil bath, and reacted at 110°C for 3 hours to obtain a reaction mixture;

[0037] Start the discharge melt pump and the devolatilization extruder, the reaction mixture obtained enters the devolatilization extruder from the reaction kettle through the discharge melt pump at 6kg / hr and carries out devolatilization 2min, and starts the feed pump simultaneously, adjusts The amount of feed and the amount of output,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com