High-heat-resistant high-weatherability ASA/PMMA (acrylonitrile-styrene-acrylonitrile and polymethyl methacrylate) composite and preparation method thereof

A composite material, high weather resistance technology, used in the field of materials and material modification, can solve the problems of unable to meet the heat resistance requirements of products, and cannot be used in environments with high heat resistance requirements, to meet the needs of industrialized large-scale production applications, excellent Appearance and performance, the effect of excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

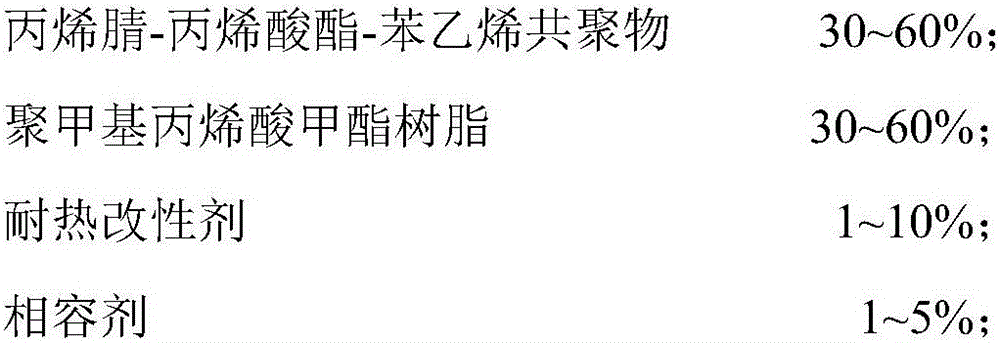

Method used

Image

Examples

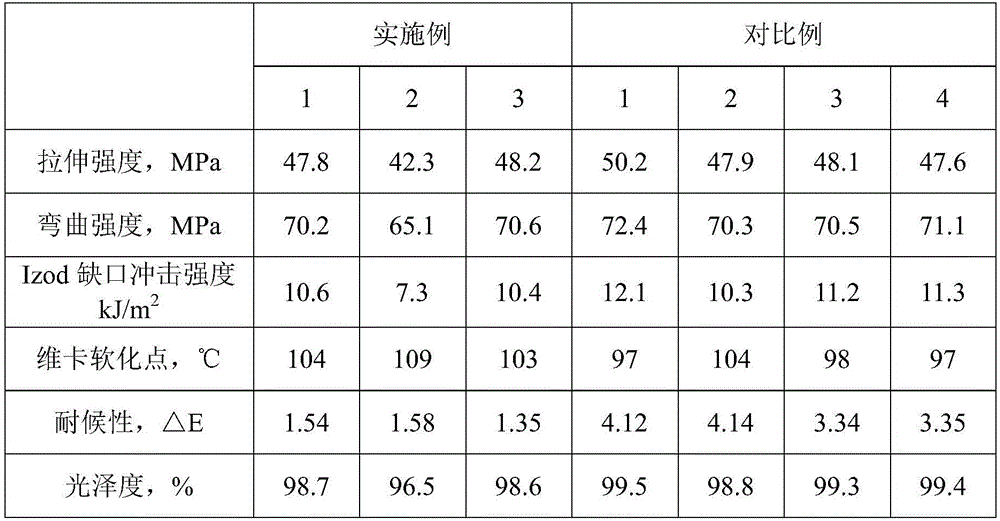

Embodiment 1

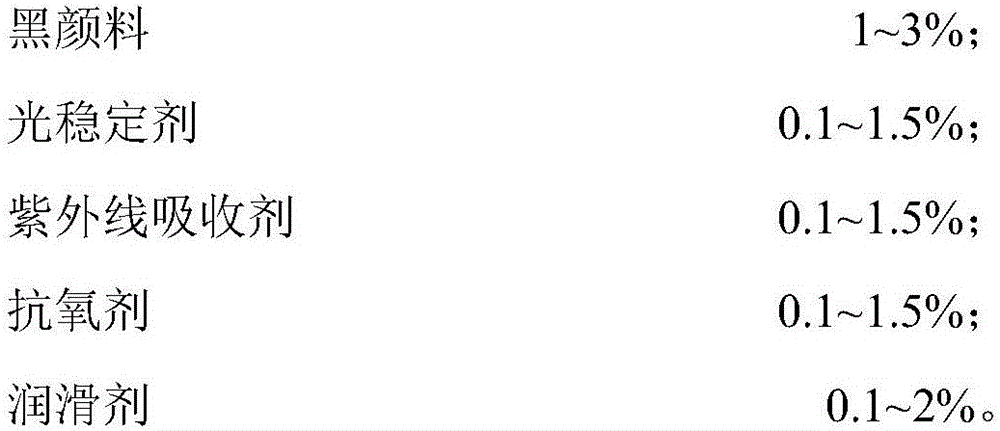

[0047] Weigh each component according to the following ratio of parts by weight: 48.4 parts of ASA resin, 40 parts of PMMA resin, 5 parts of heat-resistant modifier, 3 parts of compatibilizer, 2 parts of carbon black, 0.30 part of light stabilizer, 0.30 part of ultraviolet Absorbent, 0.50 part antioxidant, 0.50 part lubricant.

Embodiment 2

[0049] Weigh each component according to the following ratio of parts by weight: 43.4 parts of ASA resin, 40 parts of PMMA resin, 10 parts of heat-resistant modifier, 3 parts of compatibilizer, 2 parts of carbon black, 0.30 part of light stabilizer, 0.30 part of ultraviolet Absorbent, 0.50 part antioxidant, 0.50 part lubricant.

Embodiment 3

[0051] Weigh each component according to the following ratio of parts by weight: 47.8 parts of ASA resin, 40 parts of PMMA resin, 5 parts of heat-resistant modifier, 3 parts of compatibilizer, 2 parts of carbon black, 0.60 part of light stabilizer, 0.60 part of ultraviolet Absorbent, 0.50 part antioxidant, 0.50 part lubricant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com