Carbon-plastic compound material prepared by virtue of charcoal and production method of carbon-plastic compound material

A composite material and biochar technology, applied in the field of composite materials, can solve the problem of undiscovered biochar, and achieve the effects of extensive recycling, environmental protection, and compatibility improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

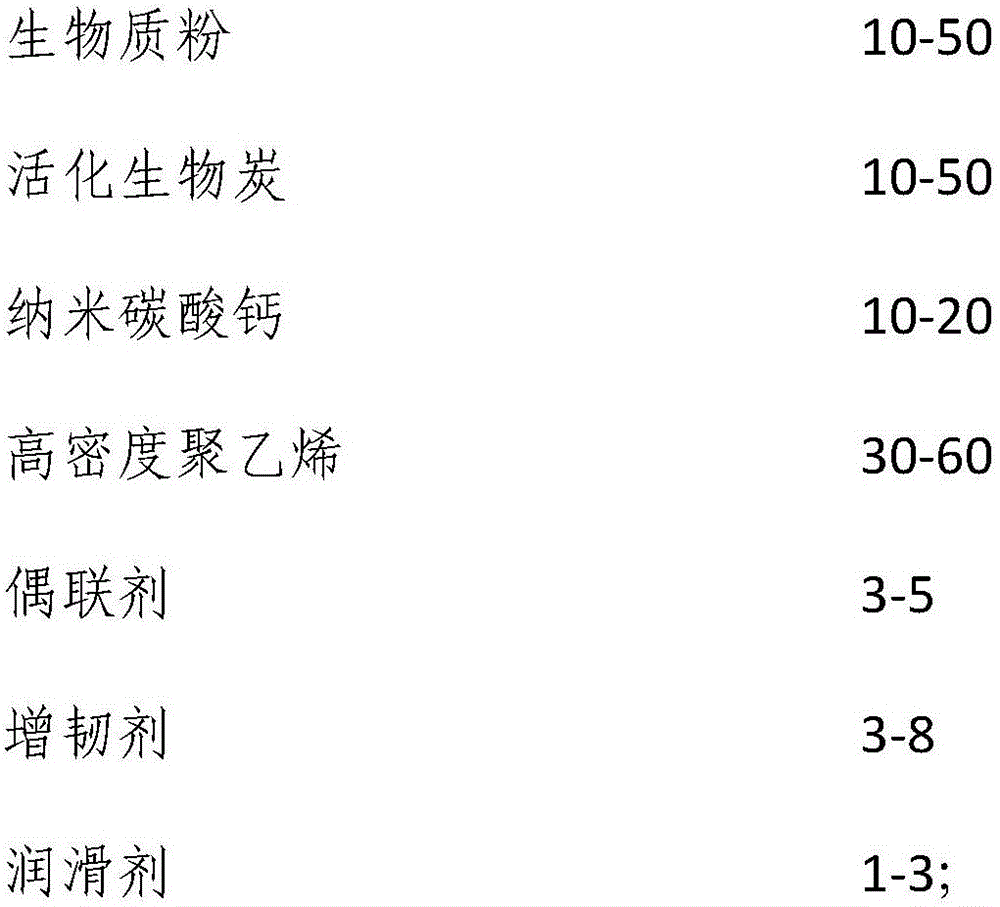

[0030] 1) Formula (unit: parts by weight)

[0031]

Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

biomass powder

50

40

30

20

10

0

Activated biochar

0

10

20

30

40

50

10

10

10

10

10

10

High-density polyethylene

40

40

40

40

40

40

coupling agent

5

5

5

5

5

5

Toughener

8

8

8

8

8

8

3

3

3

3

3

3

[0032] 2) Preparation method

[0033] Prepare according to the formula of embodiment:

[0034] 1) Add 2-3wt% maleic anhydride grafted polypropylene to the biochar particles, mix evenly, and bundle the material for 1-3 hours to obtain activated biochar;

[0035] 2) Add activated biochar, biomass powder and nano-calcium carbonate into a high-mixer and mix according to the weight ratio, the mixing temperature is 105°C-110°C, and the mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com