Flue gas treatment heat exchange tube and tube plate connection system

A technology of tube-sheet connection and flue gas treatment, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problems such as inability to weld, and achieve convenient installation and disassembly, high hardness and high impact strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

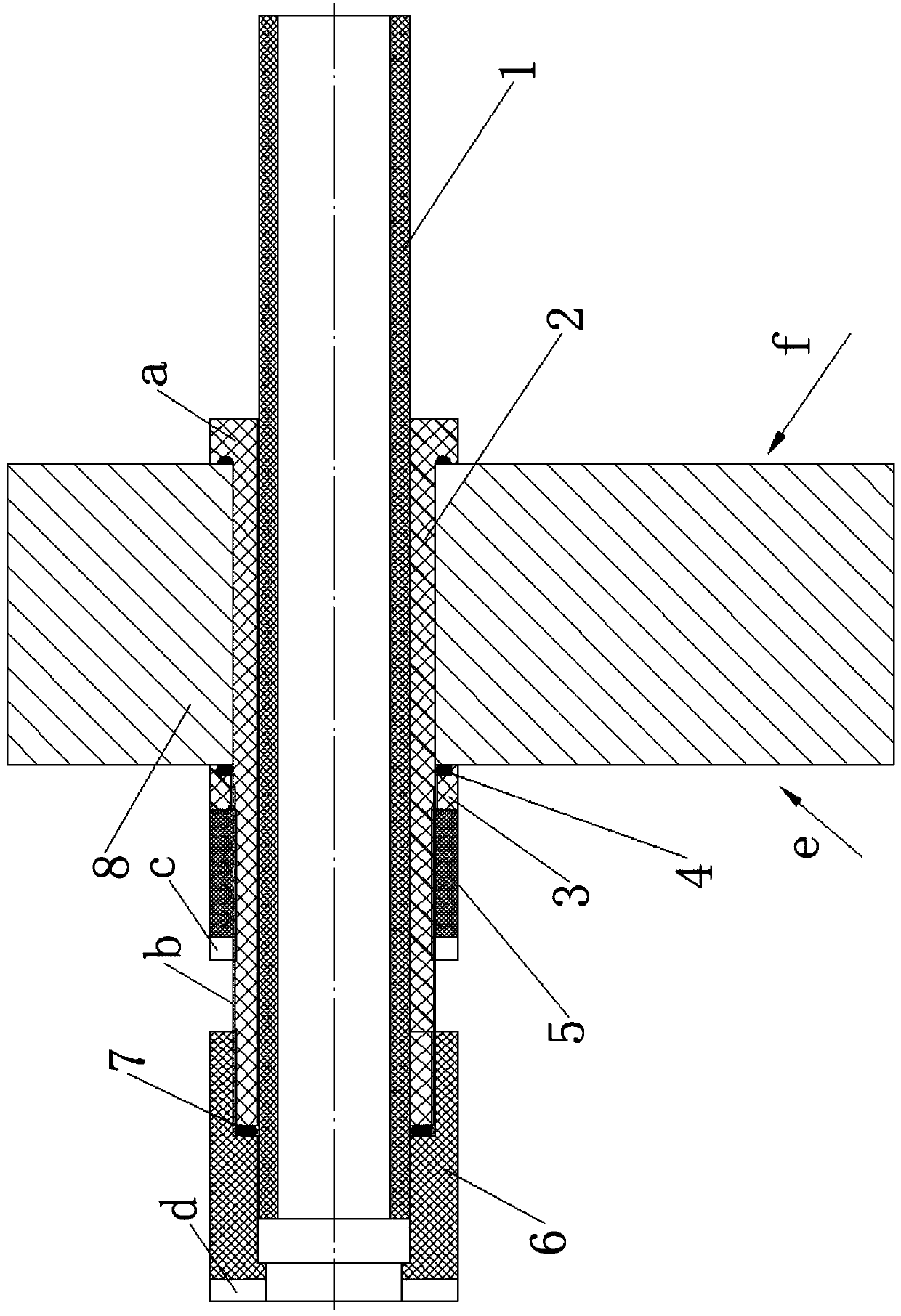

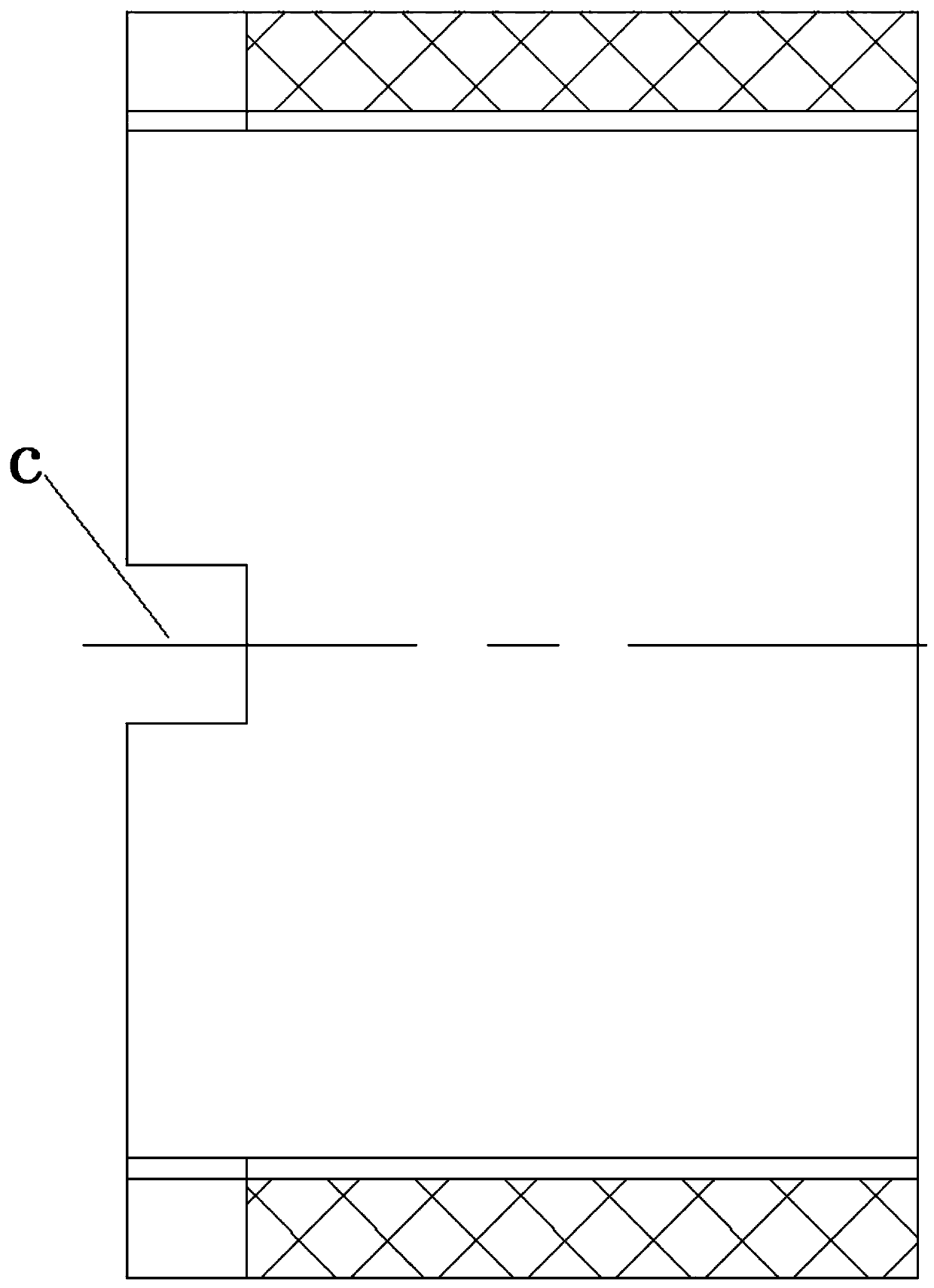

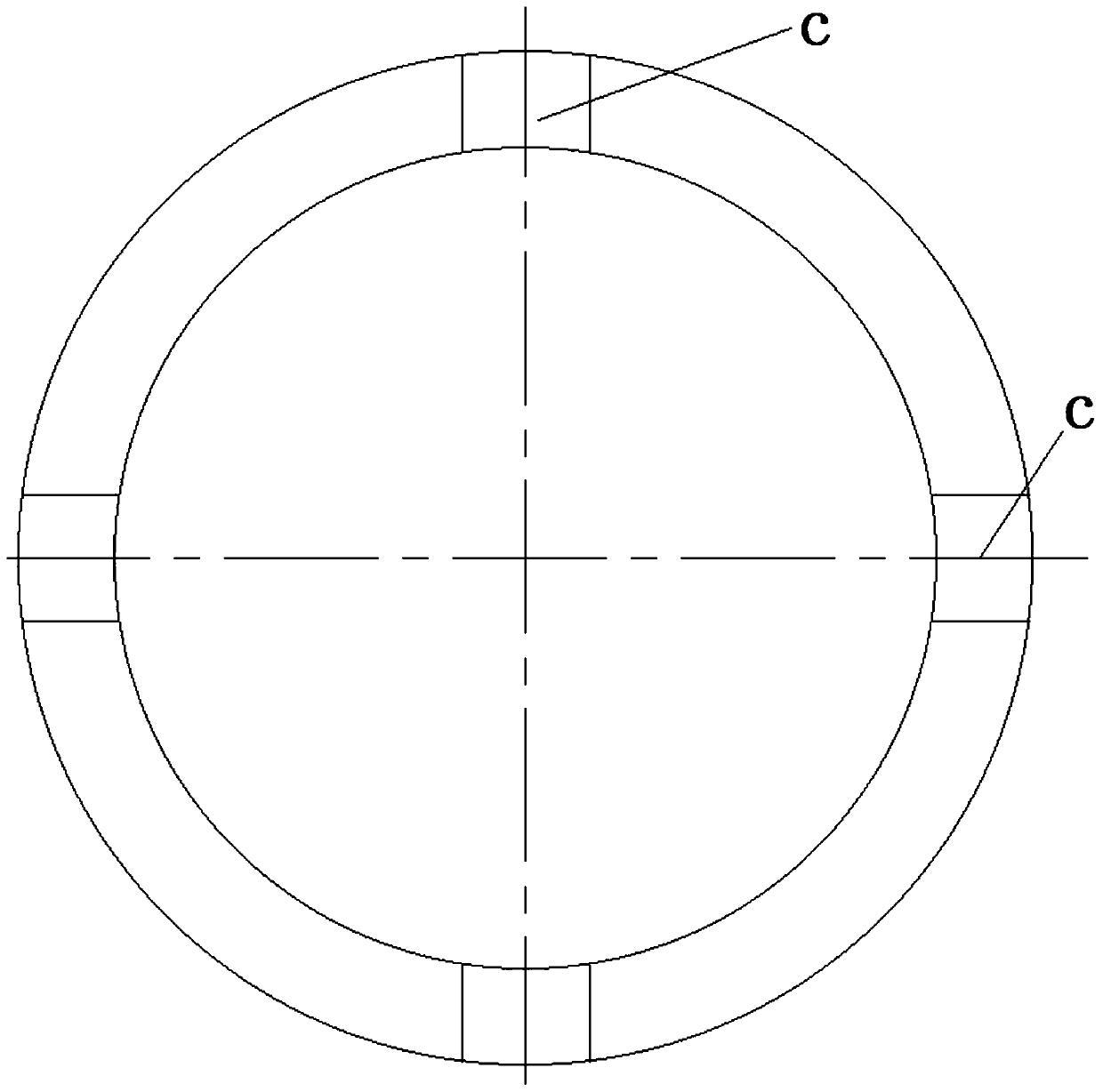

[0021] in Figure 1 ~ Figure 5 In the present invention, the flue gas processing heat exchange tube and tube sheet connection system includes a carbon plastic heat exchange tube 1 with a tube sheet stop a at one end and an external thread b at the other end and is installed on the carbon plastic heat exchange tube and tube The connecting sleeve pipe joint 2 between the plates 8, the spacer 3 installed on the connecting sleeve pipe joint close to the end surface of the tube plate, and the spacer sealing ring 4 installed between the spacer and the connecting sleeve pipe joint, The end has an installation tool insertion port c, a fastening nut 5 close to the end face of the spacer and installed on the connecting sleeve pipe joint, and the end has an installation tool insertion port d, an inner hole step type, a large hole with an internal thread and The nut type pipe clamp 6 installed on the end of the connecting sleeve pipe joint, and the pipe clamp sealing ring 7 installed betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com