Carbon-plastic electricity-conductive bipolar board for liquid energy-storing battery and manufacture thereof

A liquid flow energy storage battery and bipolar plate technology, which is applied in the direction of electrode manufacturing, active material electrodes, fuel cell parts, etc., can solve the problems of small area and large thickness, and achieve cost reduction, high conductivity, good The effect of liquid resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

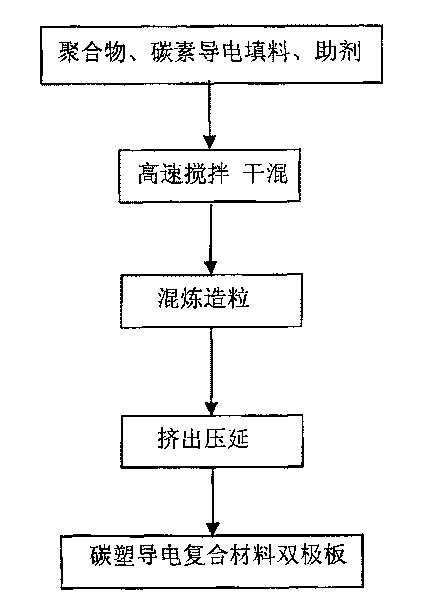

Method used

Image

Examples

Embodiment 1

[0035] Weigh respectively 10kg of polyvinyl chloride resin, 12kg of graphite powder, 0.06kg of dioctyl terephthalate (DOTP), 0.06kg of polyethylene wax, isopropyl tri(dioctyl phosphate) titanate (KR-12) 0.08kg, put into the high-speed mixer and mix, the stirring speed is 2500 rpm, the stirring time is 10 minutes / time, and the stirring frequency is 2 times. Then, it is sent to an internal mixer for mixing and granulation to obtain a carbon-plastic conductive composite material masterbatch. The mixing temperature is 180° C. and the mixing time is 5 minutes. The masterbatch is fed into the extruder, the head temperature of the extruder is 200°C, the sheet is extruded and calendered. The carbon-plastic conductive composite material bipolar plate can be prepared.

Embodiment 2

[0037] Weigh respectively 5kg of SBS (styrene-butadiene-styrene block copolymer), 5kg of polystyrene, 0.1kg of calcium stearate, and 0.1kg of vinyl silane, and put them into a high-speed stirrer for mixing, stirring The speed is 1500 rpm, stirring for 10 minutes / time, and the number of stirring times is 5 times. Then it is sent to an internal mixer for kneading and granulation to obtain a blended elastomer. The kneading temperature was 200° C., and the kneading time was 10 minutes. The above-mentioned blended elastomer and 12 kg of conductive carbon black were sent into an internal mixer for mixing and granulation to obtain a conductive masterbatch. The mixing temperature was 200° C. and the mixing time was 20 minutes. The masterbatch is fed into the extruder, the head temperature of the extruder is 200°C, the sheet is extruded and calendered. The carbon-plastic conductive composite material bipolar plate can be prepared.

Embodiment 3

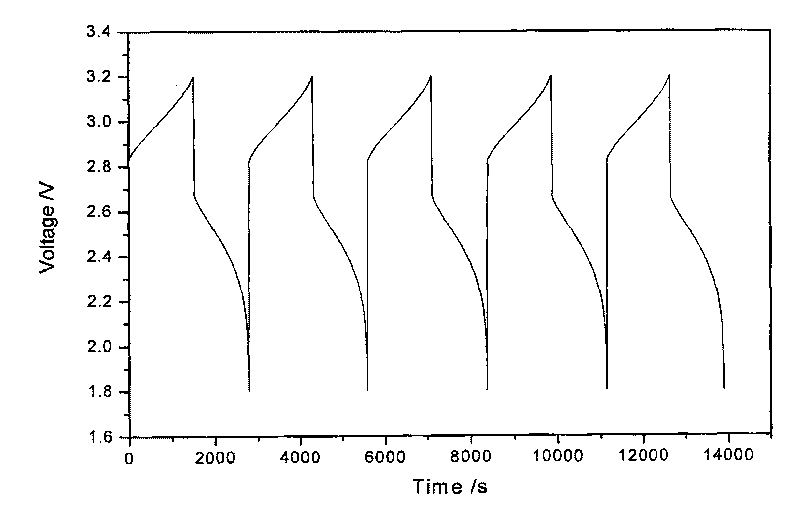

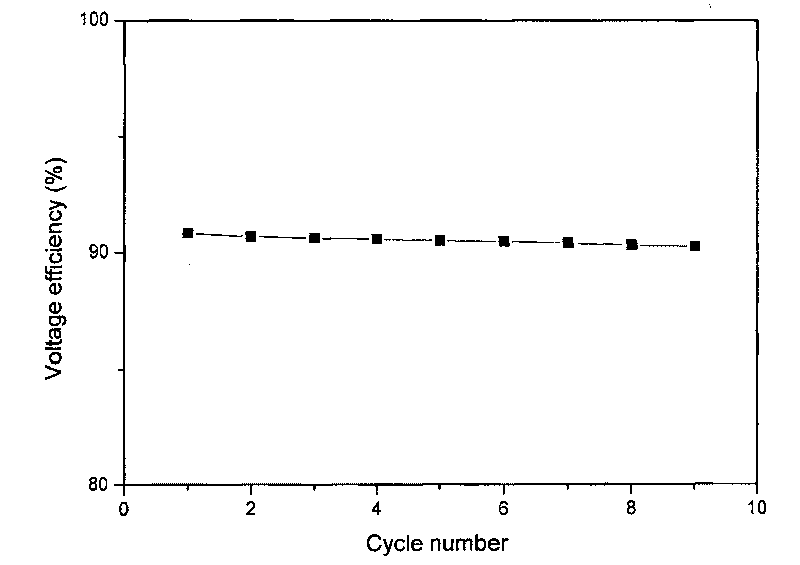

[0039] Weigh 8.5kg of polypropylene, 1.5kg of POE elastomer, 7kg of graphite, 5kg of conductive carbon black, 0.1kg of carbon fiber, 0.1kg of aminosilane, and 0.05kg of chlorinated paraffin into a high-speed stirrer, stirring twice, stirring 10 minutes / time, stirring speed 3000 rpm. Then it is sent into a twin-screw extruder for mixing and granulation to obtain a conductive masterbatch. The kneading temperature was 220° C., and the kneading time was 15 minutes. The masterbatch is sent into the extruder, the temperature of the head of the extruder is 220°C, the sheet is extruded and calendered. The carbon-plastic conductive composite bipolar plate can be obtained, the thickness of the bipolar plate is 1mm, the length is 700mm, the width is 500mm, and the area is 3500cm 2 . Use this bipolar plate to assemble an all-vanadium flow energy storage battery stack. The battery stack is composed of 15 cells, and the positive electrolyte is 1.5MVO. 2+ 40l of 3M sulfuric acid solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com